Hybrid intelligence soft measuring method of overflow granularity index in wet grinding process

A soft measurement and particle size technology, applied in the direction of measuring devices, particle size analysis, particle and sedimentation analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

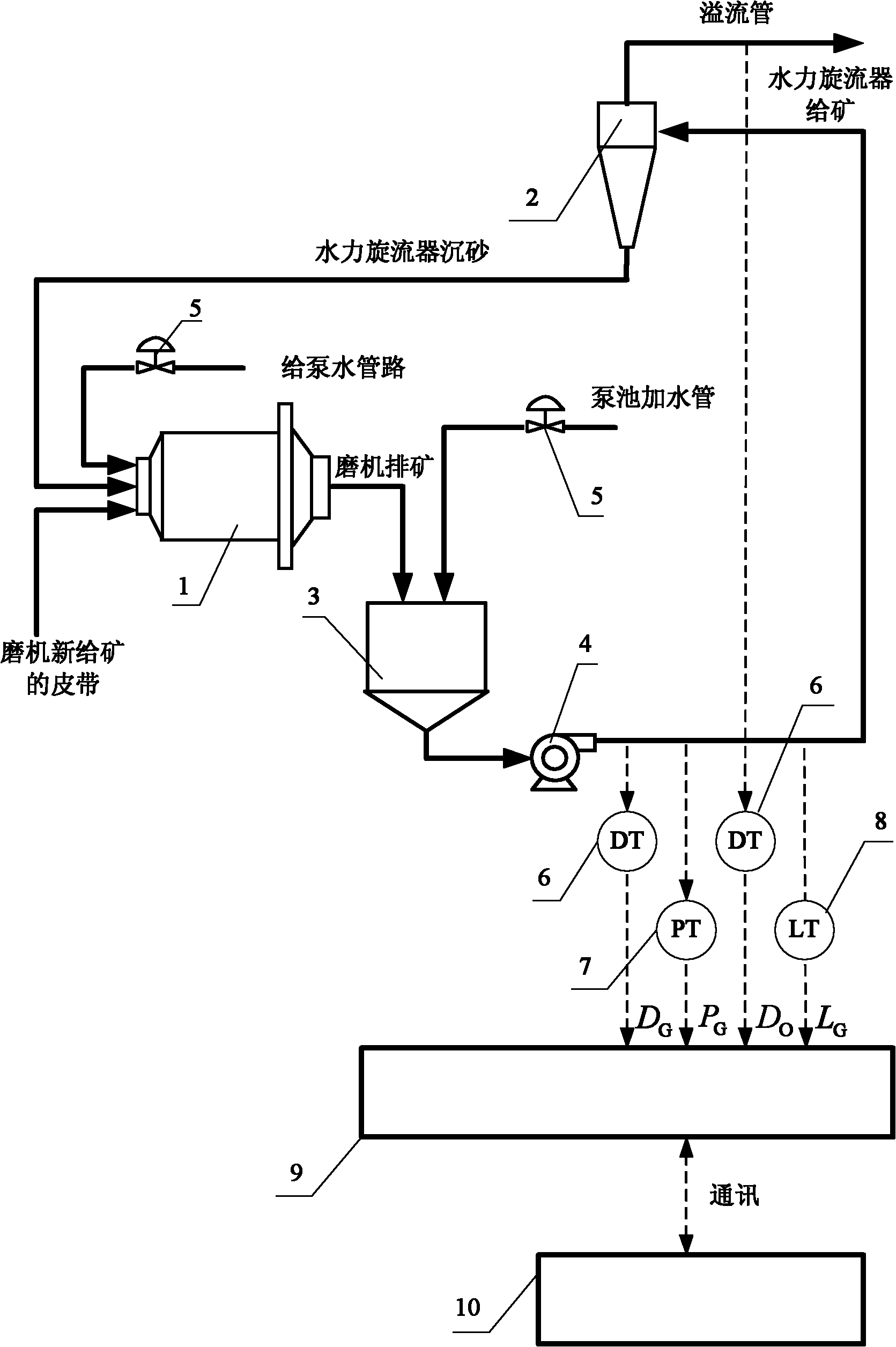

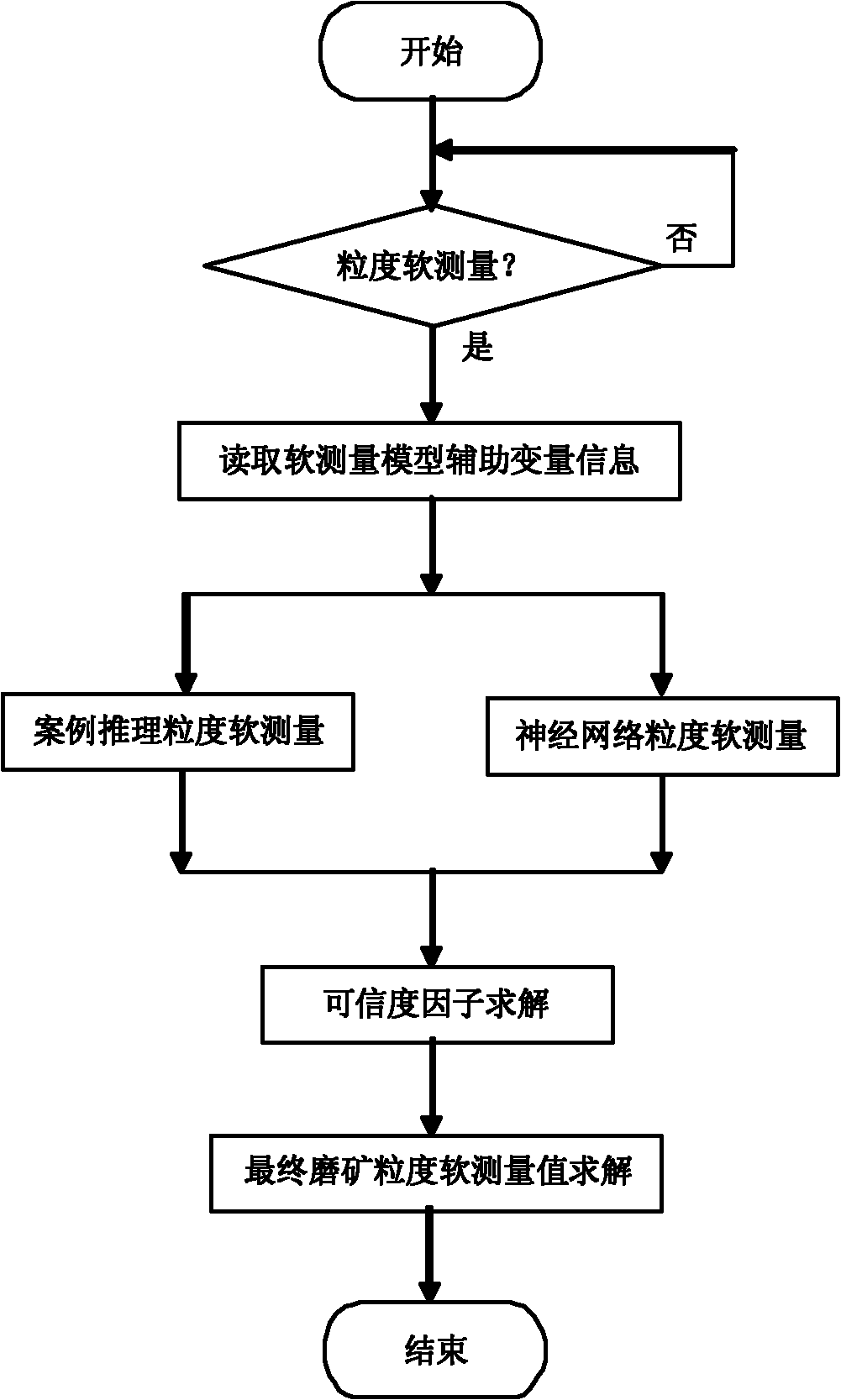

[0116] Taking the grinding and classification section of a hematite dressing plant as an implementation case, the specific process of the grinding process of the dressing production is as follows figure 1 As shown, wherein, the solid line arrow represents the logistics (raw ore, water and pulp), and the dotted line represents the signal flow,

[0117] Hydrocyclone feeding pressure——P G

[0118] Hydrocyclone feeding flow rate——L G

[0119] Hydrocyclone feeding concentration——D G

[0120] Hydrocyclone overflow concentration——D O

[0121] Hydrocyclone overflow concentration——D O

[0122] Auxiliary variable information set for soft sensor model - O C

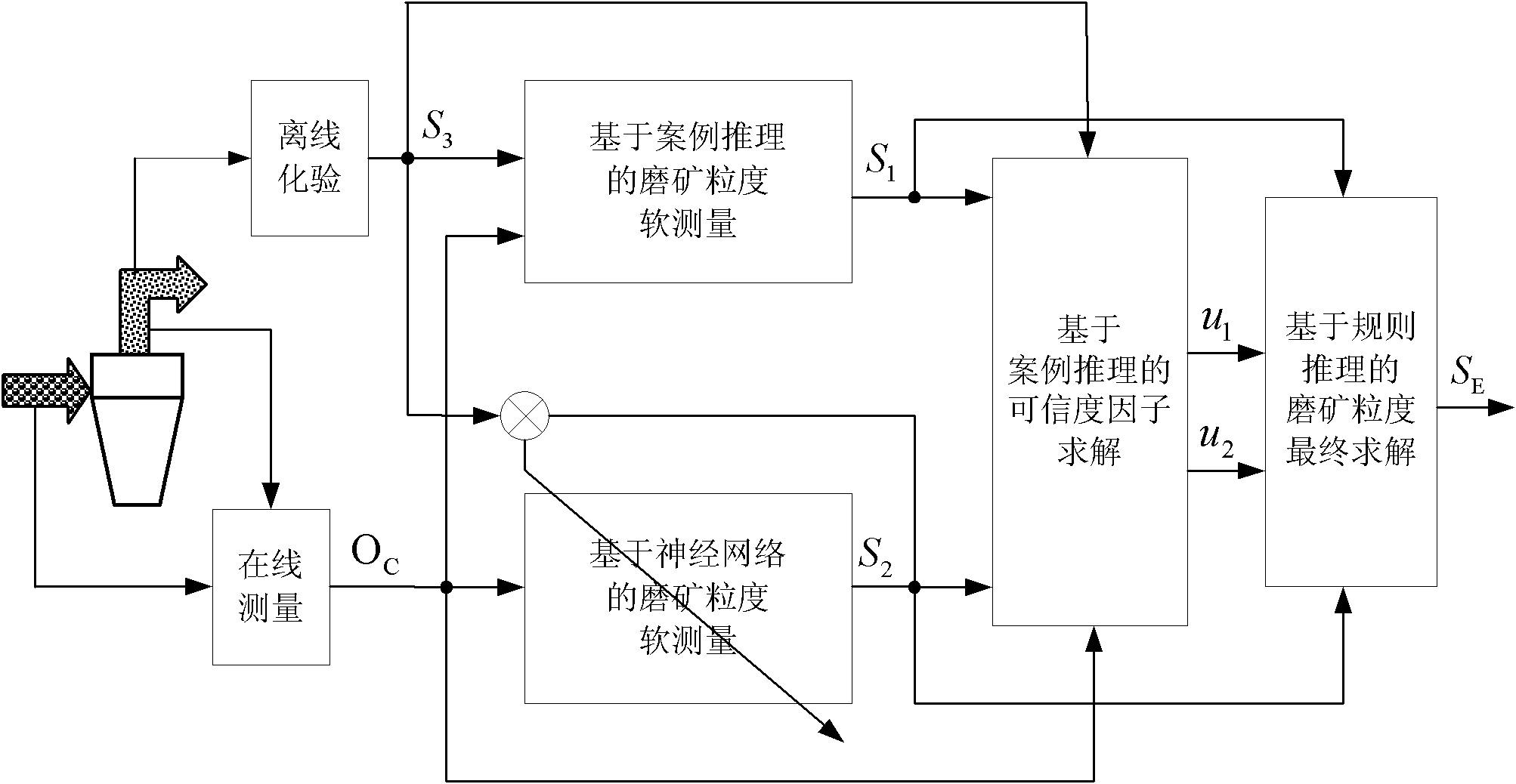

[0123] Granularity Estimation for Case-Based Reasoning Soft-Sensor Models - S 1

[0124] Granularity Estimation for Neural Network Soft-Sensor Models——S 2

[0125] The actual test value of grinding particle size——S 3

[0126] (final) soft measure of grinding particle size - S E

[0127] Confidence Factors for Granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com