Air knife of coated glass cleaning machine

A glass cleaning and coating glass technology, which is applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of residual water marks on the side of the glass, poor air-drying effect, the size and width of the air outlet Difficult to adjust and other problems, to achieve the effect of enhancing the air-drying effect, ensuring linearity, and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] What the present invention protects is an air knife for a coated glass cleaning machine. As long as those skilled in the art understand the embodiment of the present invention, without creative work, only equivalent technical replacements are within the scope of protection of the present invention.

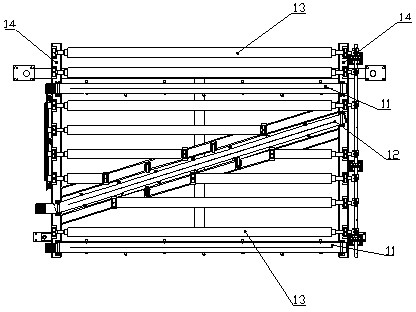

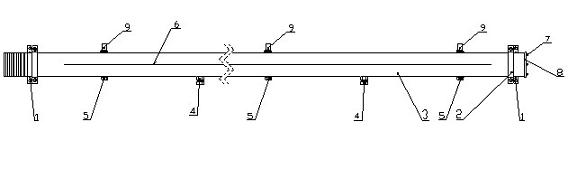

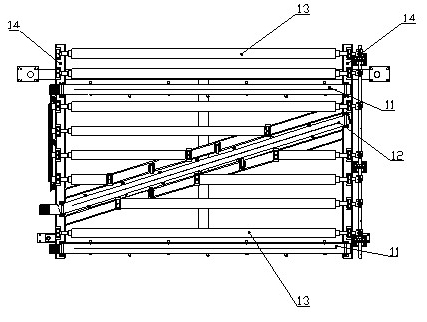

[0019] refer to Figure 1~2 shown, said figure 1 It is a top view of the air knife of the washing machine, in which only the structural schematic diagram of the upper air knife is shown. figure 2 It is a schematic diagram of the clamping structure of the air knife of the washing machine, wherein the lower air knife and the upper air knife are symmetrically arranged on the upper and lower sides of the glass, and the upper air knife includes at least two straight air knives 11 and oblique air knives. 12. A number of transmission rollers 13 and brackets 14. The oblique air knives 12 are arranged at the opposite corners of the two straight air knives 11. Wherein, both the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com