High-speed precision cutting machine head

A cutting machine and precise technology, applied in metal processing and other directions, can solve the problems of few functions, inability to use flexible materials for cutting, unreasonable structure, etc., and achieve the effect of cost saving, favorable for mass production and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

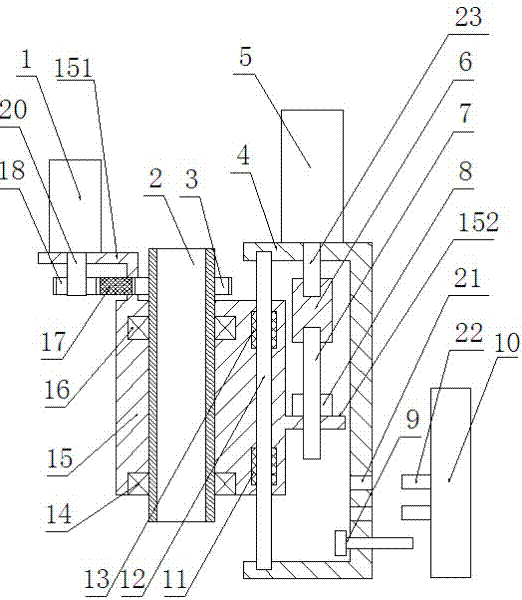

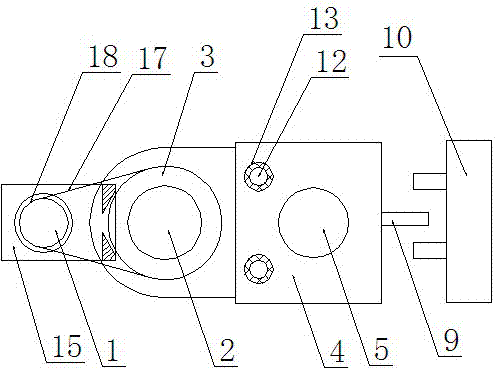

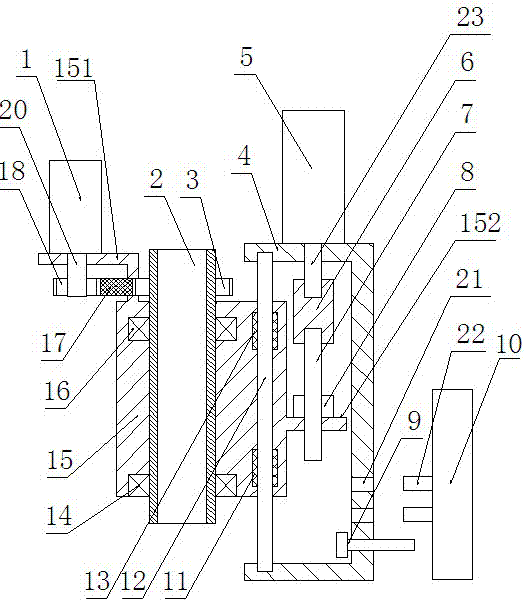

[0017] see Figure 1 ~ Figure 2 , this embodiment takes a single cutter head as an example for illustration.

[0018] The present invention includes a first motor 1, a second motor 5, a sleeve seat 15, a sleeve 2, a sleeve timing pulley 3, a bracket 4, a shaft coupling 6, a screw mandrel 7, a screw mandrel nut 8, a guide post 12, Base 10, motor synchronous pulley 18 and synchronous belt 17. Among them: the sleeve 2 is a hollow structure, the guide post 12 is linear, the sleeve 1 is parallel to the guide post 12; the sleeve seat 15 is fixedly connected with two parallel sleeve seat platforms 151, 152, The first motor 1 and the screw nut 8 are respectively fixed on the platforms 151, 152; the first motor 1 and the second motor 5 are located at the upper end of the whole machine head, the center line of the first motor shaft 20, the center of the second motor shaft 23 The line and the center line of the sleeve 2 are all parallel to each other; the base 10 is connected to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com