Rubber diaphragm circulation forming device

A rubber diaphragm and molding device technology, which is applied in the field of rubber diaphragm cycle molding devices for automobile brake chambers, can solve the problems of low production efficiency, long production cycle, and low equipment utilization rate, and achieve less space occupation and lower labor intensity , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the examples.

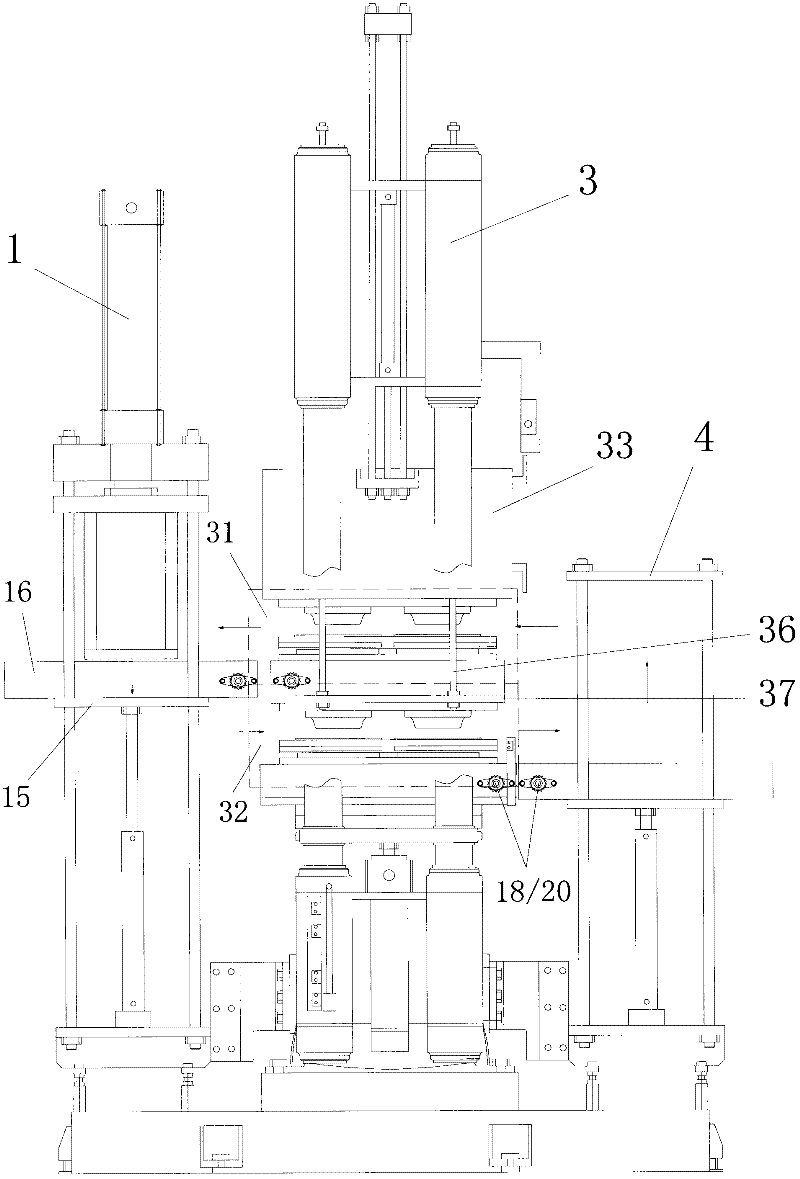

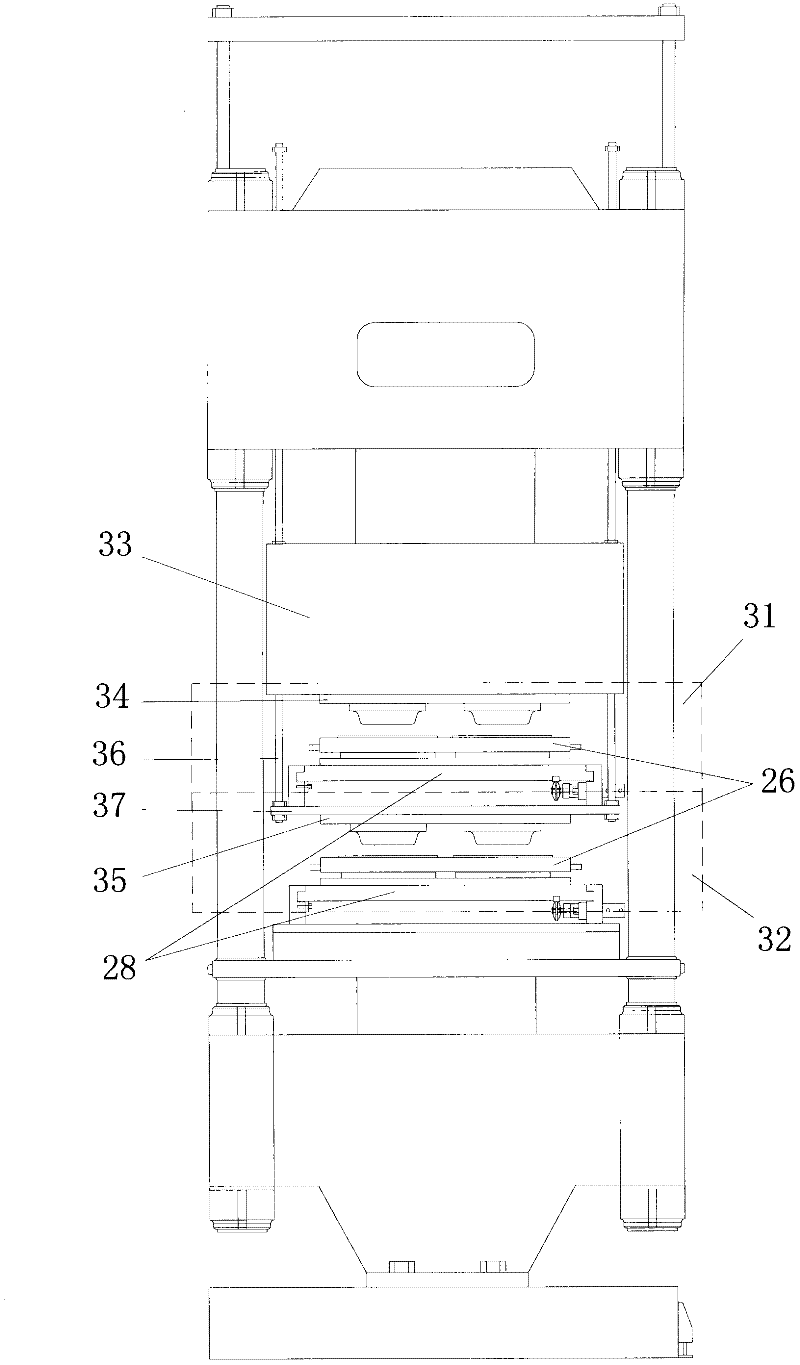

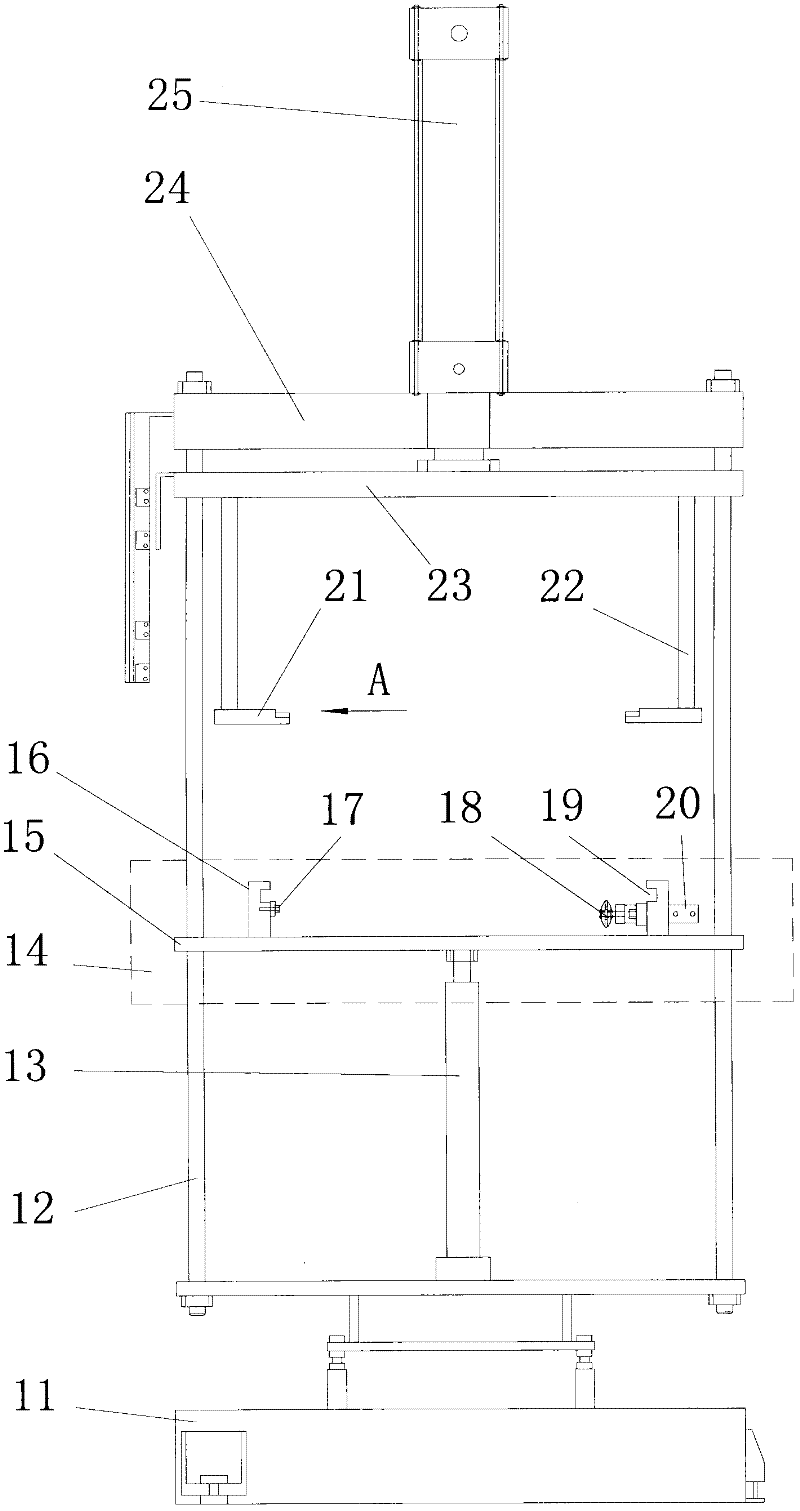

[0030] Figure 1-Figure 7 Be embodiment 1 of the present invention.

[0031] like figure 1 As shown, the rubber diaphragm cycle molding device of the present invention includes a mold separation mechanism 1, a vacuum vulcanization press 3, a worktable lifting mechanism 4 and a rubber diaphragm vulcanization molding mold; see figure 2 , Figure 9 , wherein, the rubber diaphragm vulcanization molding mold is a compound mold structure that includes 4 sets of vulcanization molding mold units, including a lower template, a middle template 26, a first upper template 35, a second upper template 34, the lower mold in each unit, the pressure The ring, the upper die for primary vulcanization and the upper die for secondary vulcanization are respectively arranged on the lower die plate, the middle die plate 26, the first upper die plate 35 and the second upper die plate 34.

[0032] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com