Permanent calibration method in soft bearing dynamic unbalance test of rigid rotor

A technology of dynamic unbalance and rigid rotor, which is applied in static/dynamic balance test, machine/structural component test, measuring device, etc., and can solve problems such as inability to achieve calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

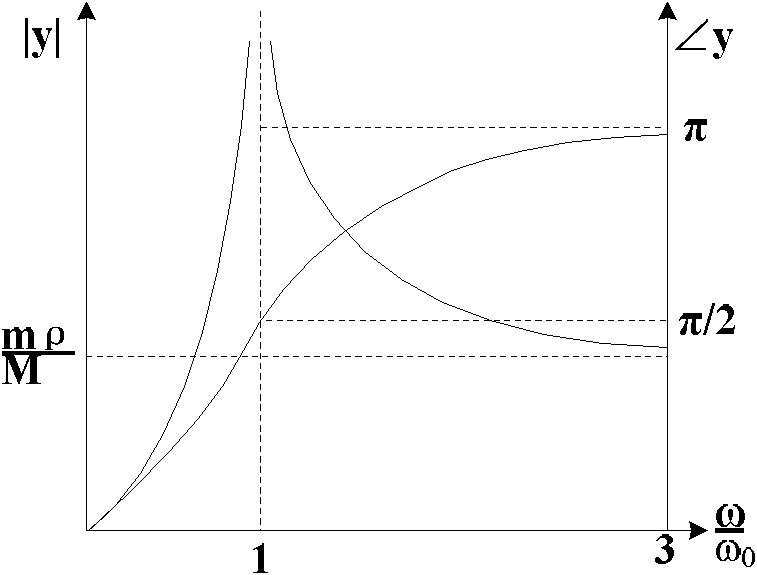

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

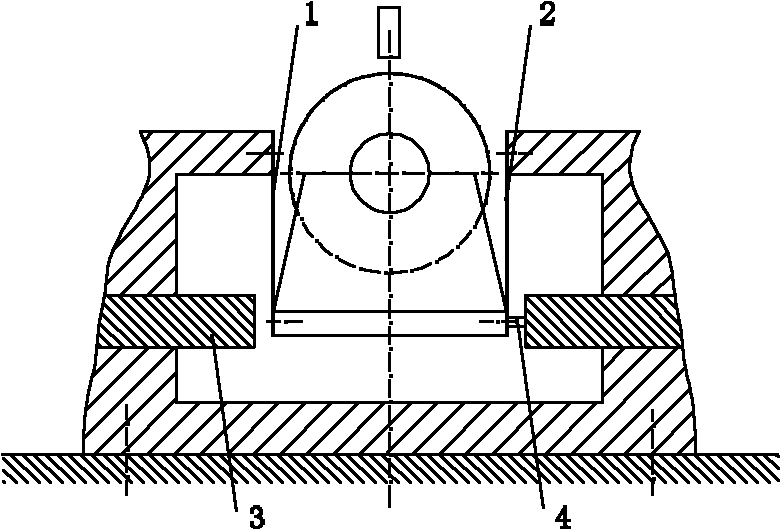

[0025] Such as image 3 As shown, this embodiment includes the following steps:

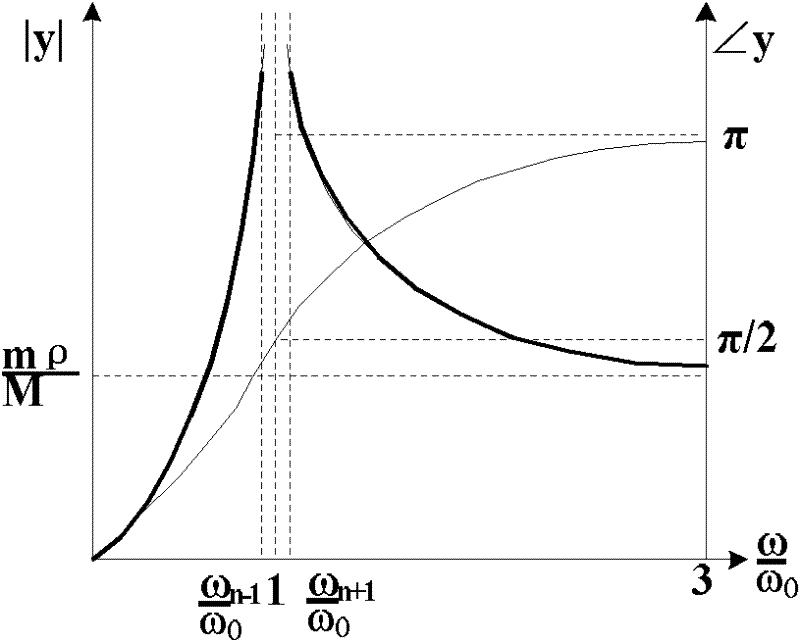

[0026] In the first step, in order to obtain the parameters of the rotor acceleration process more delicately, the balancing machine uses a servo motor with preset speed and acceleration functions to drive the rotor, and the support is started only when the rotor reaches the resonance state (maximum amplitude) to the greatest extent. The locking device of the pendulum system releases the locking device supporting the pendulum immediately after passing the resonance frequency point.

[0027] In the second step, during the acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com