High-power optical burn-in

A light-aging, high-power technology, applied in optics, light guides, lasers, etc., can solve problems such as inability to properly screen out lasers, unreliable structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

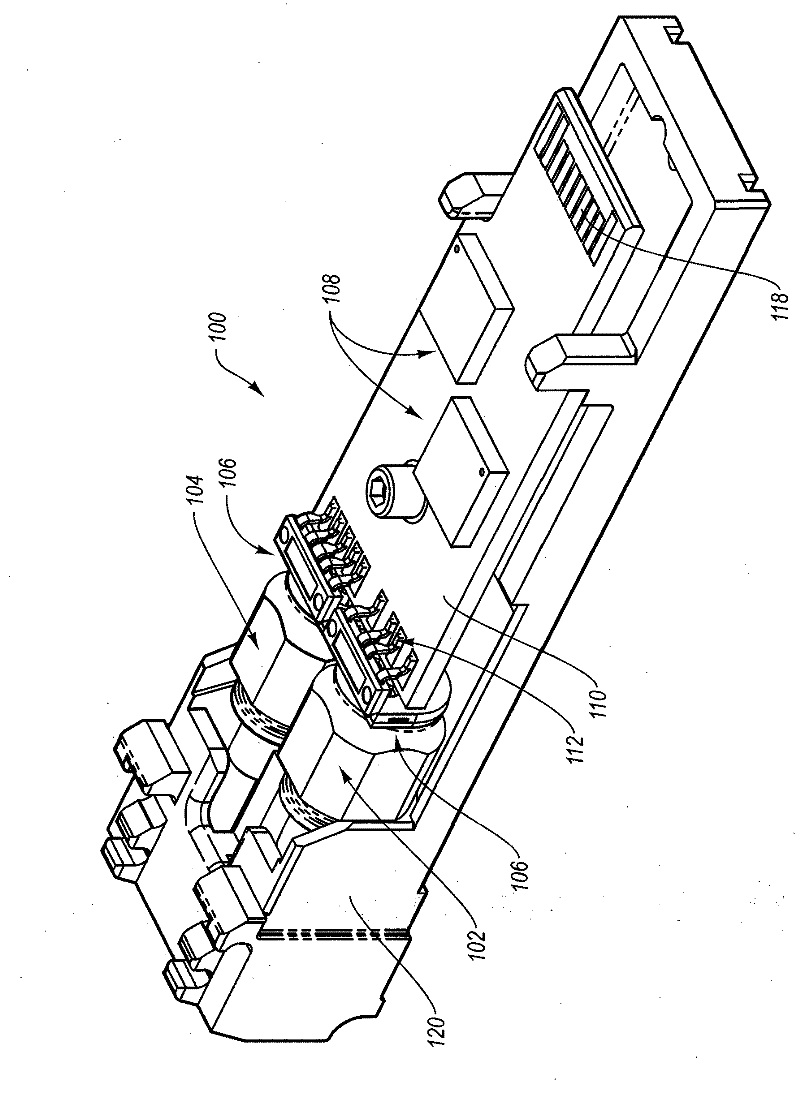

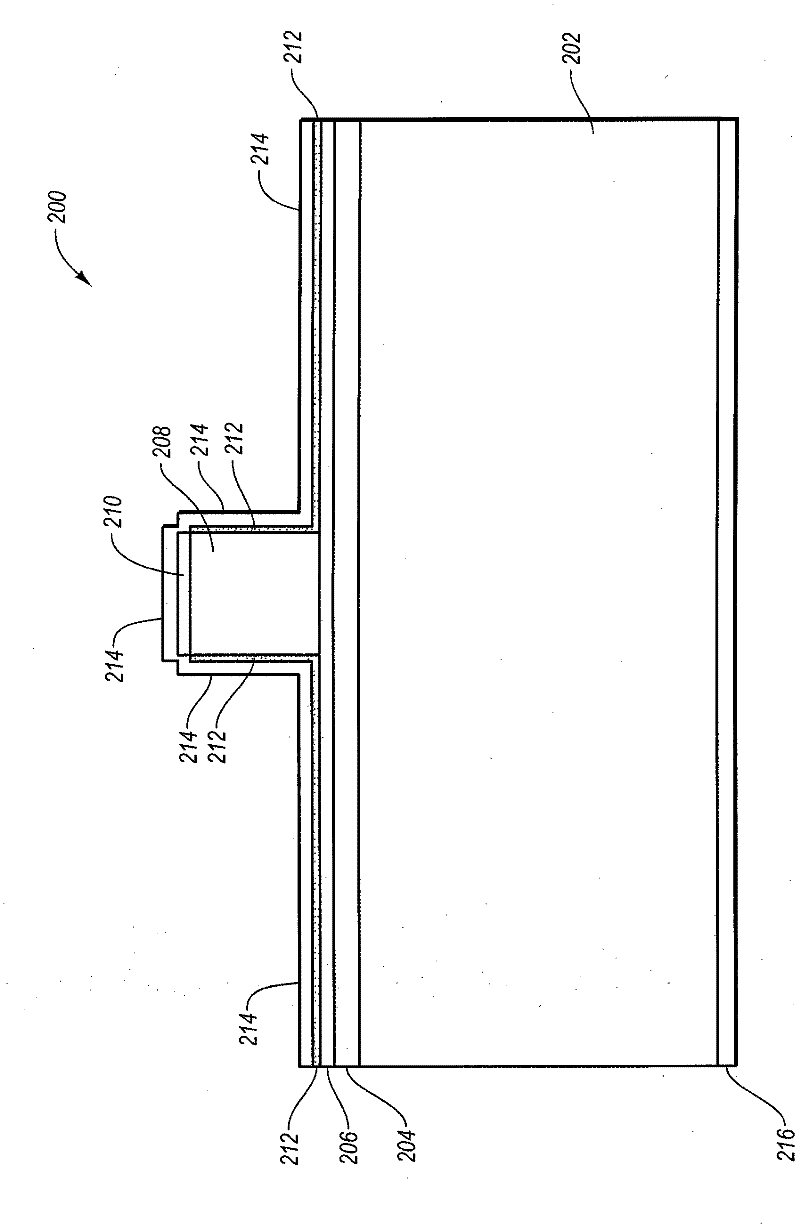

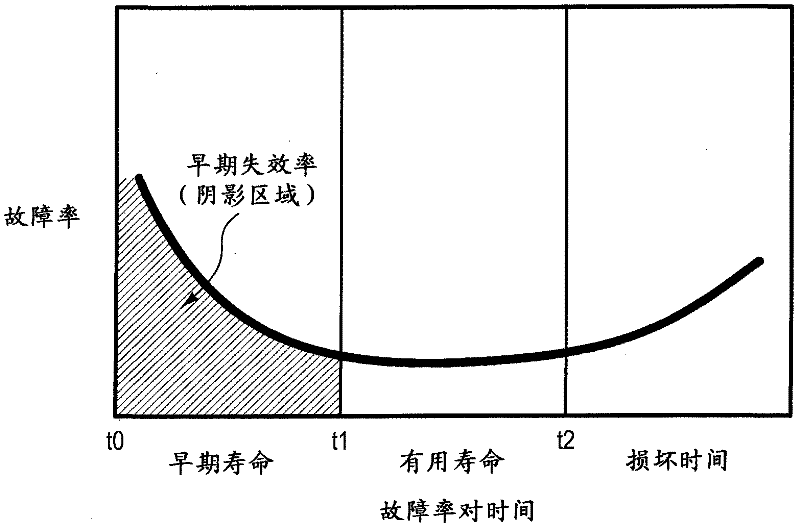

[0019] Embodiments of the present invention relate to methods and systems for testing optoelectronic devices such as, but not limited to, laser diodes. The methods and systems of the present invention provide identification of defective and / or unreliable laser diodes that cannot be identified by conventional TBI methods. In contrast to traditional TBI burn-in, embodiments of the present invention include operating at relatively large drive currents (such as three to four times the normal operating bias current at elevated temperatures) and relatively low temperatures, such as room temperature Device aging treatment. Embodiments of the present invention may help to identify problematic optoelectronic devices to improve the reliability of the devices ultimately sold to the laser manufacturer / seller's customers.

[0020] Reference will now be made to the drawings, wherein like structures will be designated with like reference numerals. It is to be understood that the drawings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com