Gelatinization and solidification stabilization treatment system for waste incineration fly ash

A waste incineration fly ash and stabilization treatment technology, which is applied in the field of environmental engineering, can solve the problems of fly ash heavy metal stabilization effect and poor weather resistance, poor fly ash ratio adjustment, poor mixing uniformity, etc., to ensure the effect of stable disposal , high adjustability and expandability, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

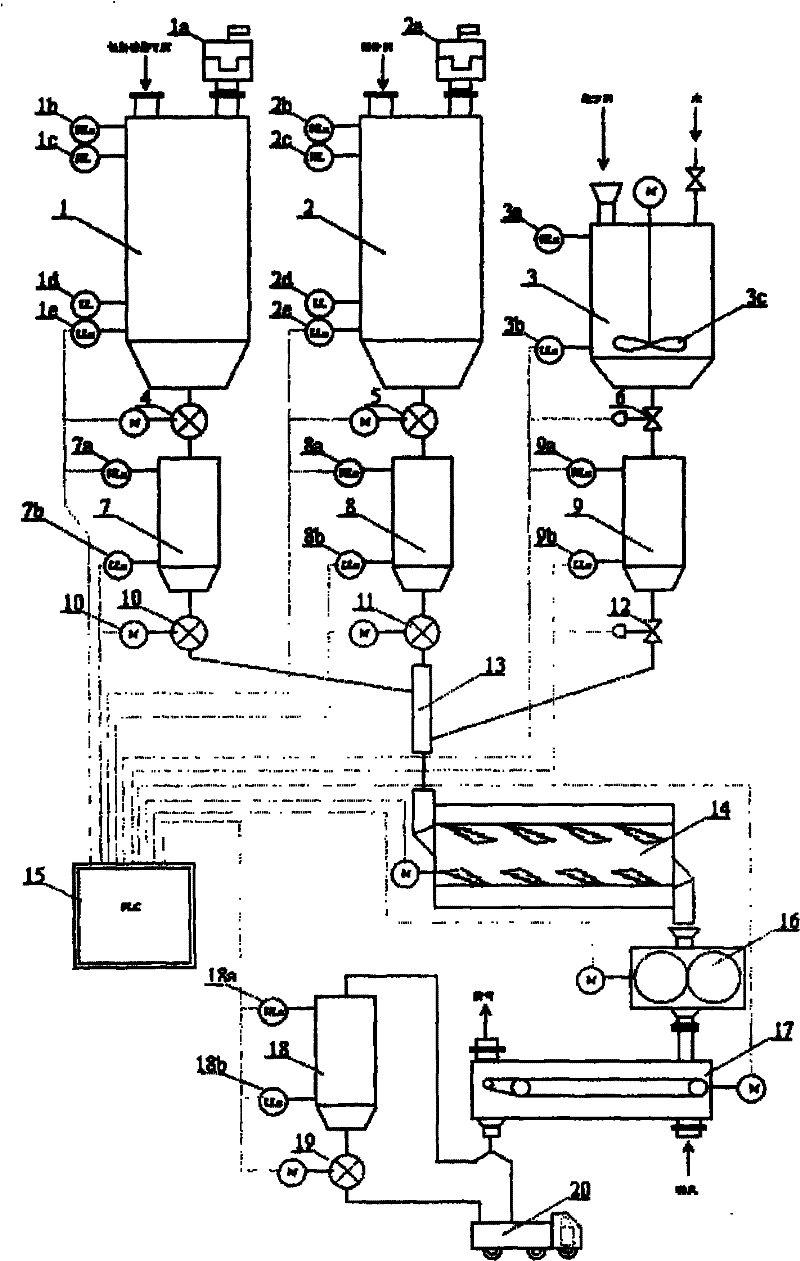

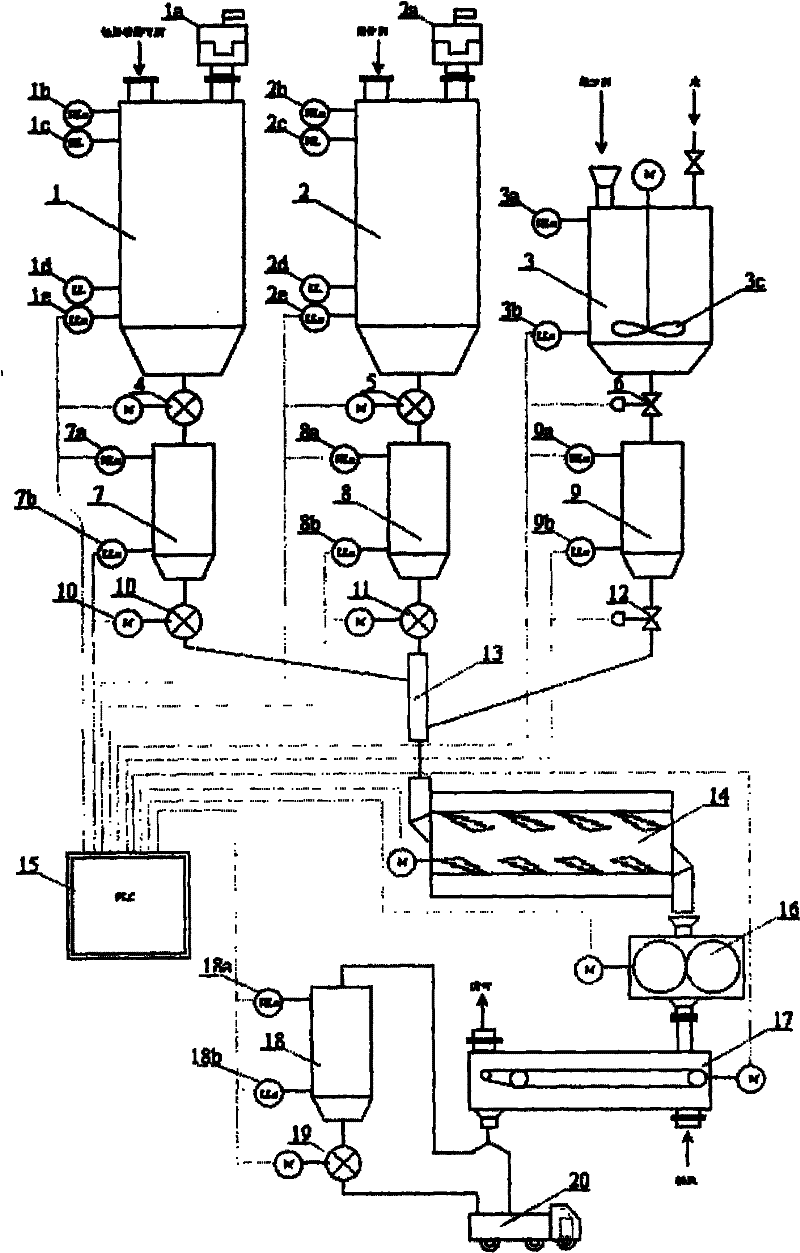

[0013] The following is a detailed description of a gelling, solidifying and stabilizing treatment system for waste incineration fly ash of the present invention in conjunction with the accompanying drawings:

[0014] see Attachment.

[0015] A gelling, consolidating and stabilizing treatment system for waste incineration fly ash. The treatment system is composed of a fly ash storage and metering device, a curing agent storage and metering device, a stabilizer storage and metering device, and a homogeneous mixing and extrusion granulation treatment device.

[0016]Among them, the garbage fly ash storage and metering device consists of a fly ash storage bin 1, a fly ash metering tank 7, a first high-level controller 1b, a fourth high-level controller 7a, a first low-level controller 1e, and a fourth low-level controller 7b , the first high-level alarm 1c and the first low-level alarm 1d, the first electric control valve 4 and the fourth electric control valve 10, the waste inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com