Motor assembly special for six-roller invertible rolling mill

A technology for special motors and rolling mills, which is applied in the structural field of special motor units for rolling mills, can solve problems such as slow rolling speed, high motor current, and affecting equipment production capacity, and achieve the goals of increasing operating speed, reasonable structure, and increasing rolling output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

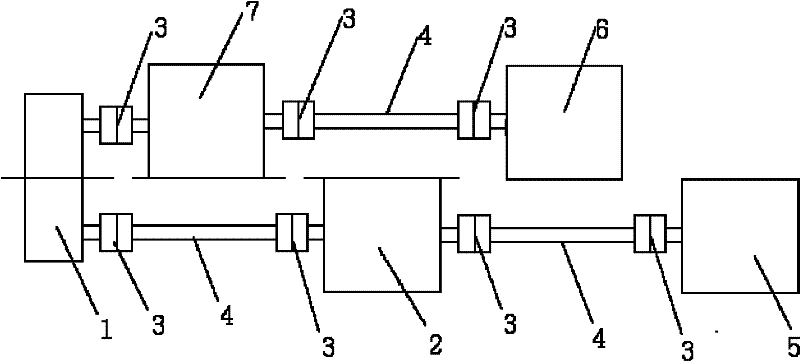

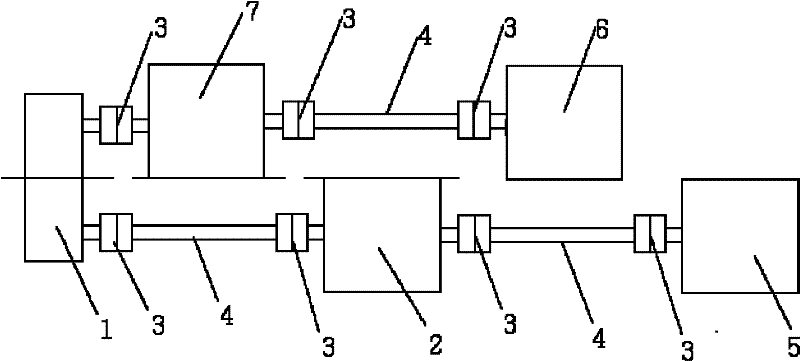

[0010] refer to figure 1 , the main reducer 1 is connected with the main motor 7 of the lower roller through the coupling 3, the main motor 7 of the lower roller is connected with the combination of the transmission shaft 4 and the coupling 3 through the coupling 3, and the coupling 3 and the transmission shaft 4 The combined connection with the coupling 3 is connected with the slave motor 6 of the lower roller, and the main reducer 1 is connected to the main motor 2 of the upper roller through the combination of the coupling 3 and the transmission shaft 4 and the coupling 3, and the main motor 2 of the upper roller passes through The coupling 3 and the combination of the power transmission shaft 4 and the coupling 3 are connected to the upper roller slave motor 5 and assembled into one body.

[0011] The adoption of the present invention realizes that the upper and lower rollers of the motor unit have two motors operating together at the same time, which increases the power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com