Angle cutting mould for unfolded material of carriage trough girder

A technology of grooved beam and unrolling material, applied in the field of blanking die, can solve the problems of poor machining accuracy, affecting product quality, and high labor intensity, so as to improve machining accuracy, reduce parts turnover and positioning processes, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

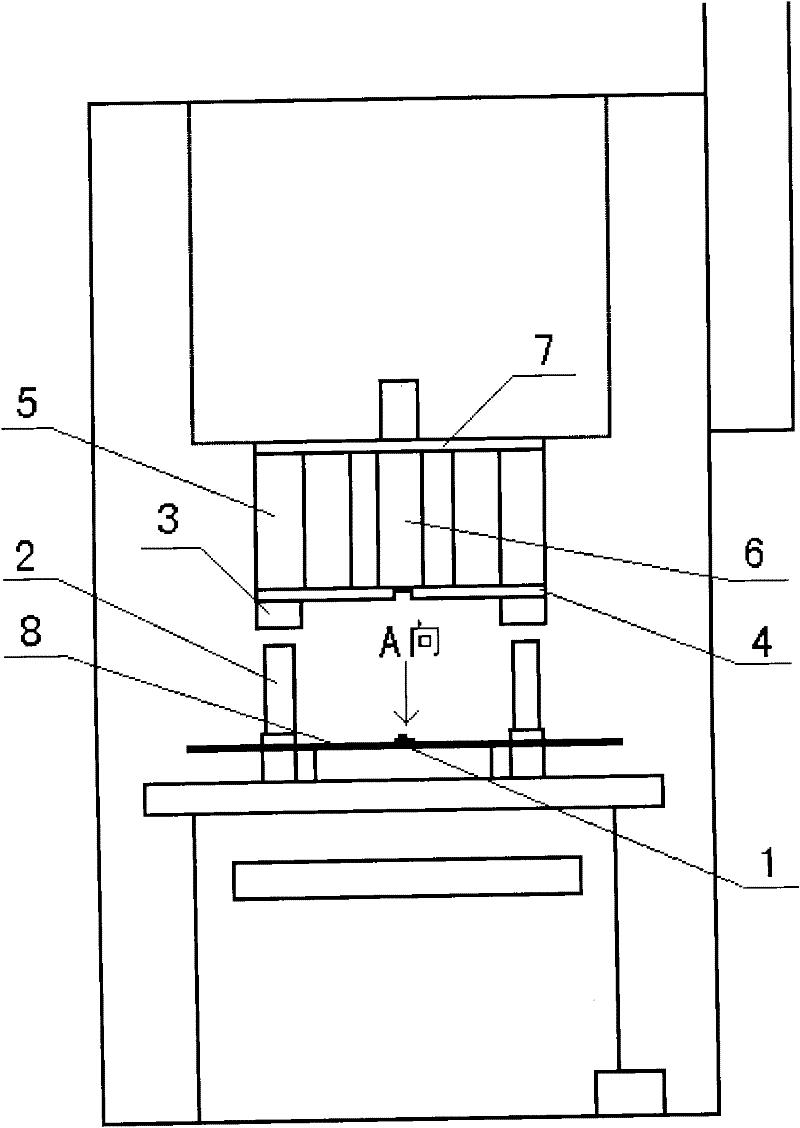

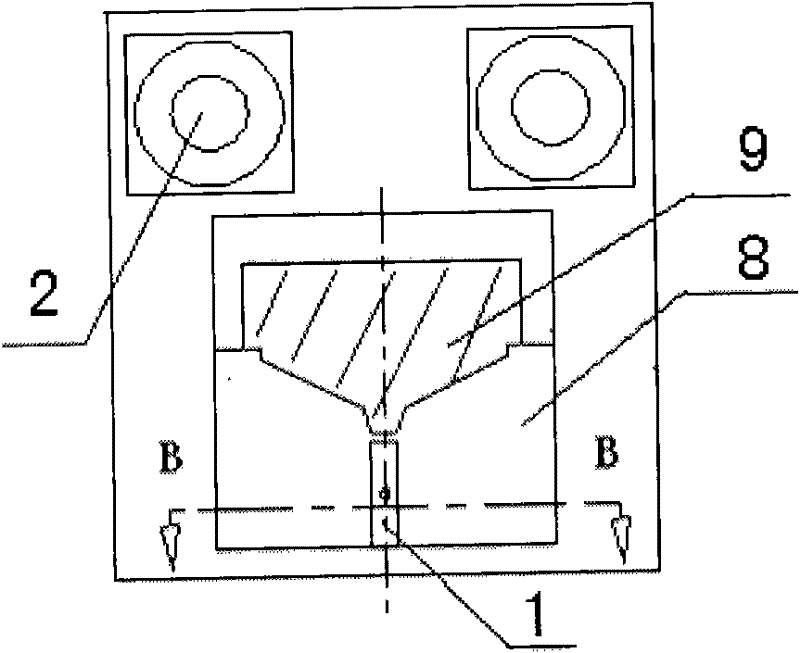

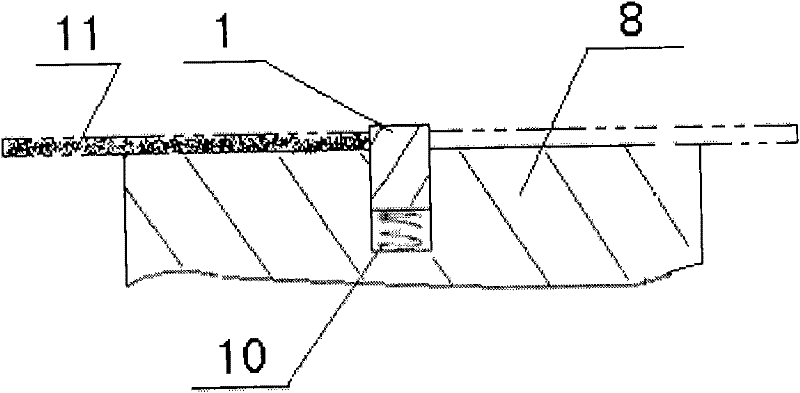

[0016] refer to Figure 1-Figure 3 , the carriage channel beam of the present embodiment expands the material angle cutting die, and it comprises upper mold base 7, lower mold base 8, is provided with the punch 6 of double edge, near the blanking opening 9 at the centerline position of lower mold base 8 There is a positioning block 1 that can be stretched up and down. The lower mold base 8 is provided with a groove corresponding to the positioning block 1. The bottom of the groove is provided with a spring 10. The positioning block 1 is embedded in the groove of the lower mold base. The spring 10 The upper end connects the positioning block 1.

[0017] The lower mold base 8 is provided with a guide column 2, corresponding to it, the upper mold base 7 is provided with a guide sleeve 3, and when the upper mold base falls, the guide column 2 is just inserted into the guide sleeve 3.

[0018] It also includes a discharge plate 4 and a polyurethane discharge rubber block 5. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com