Modular surface cleaning device for permanent magnet ferrite-tile-shaped magnet mould

A permanent magnet ferrite and cleaning device technology, applied in the manufacture of tools, presses, etc., can solve problems affecting the quality of cycle products and difficulties in the automatic production of magnetic tile products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

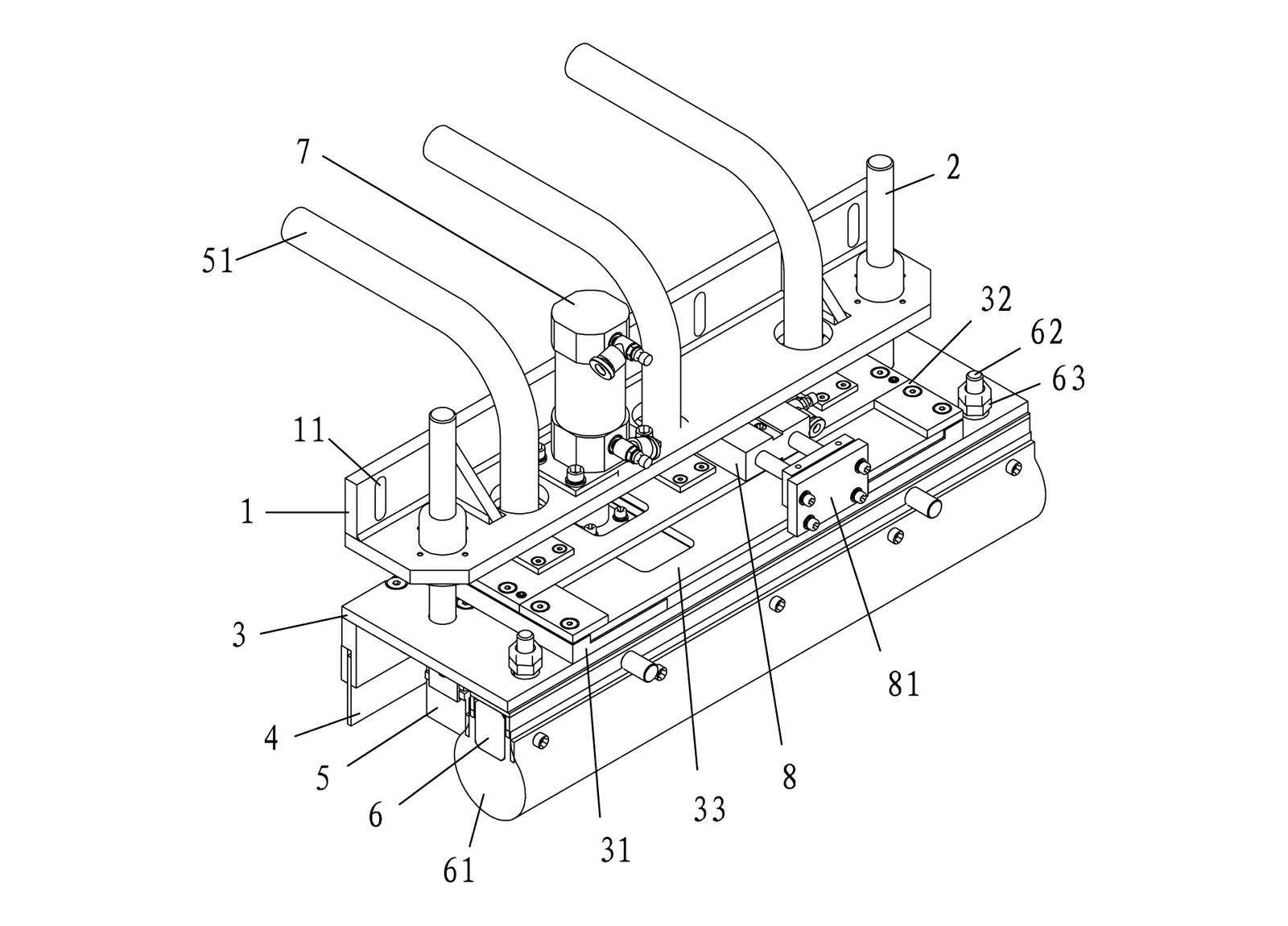

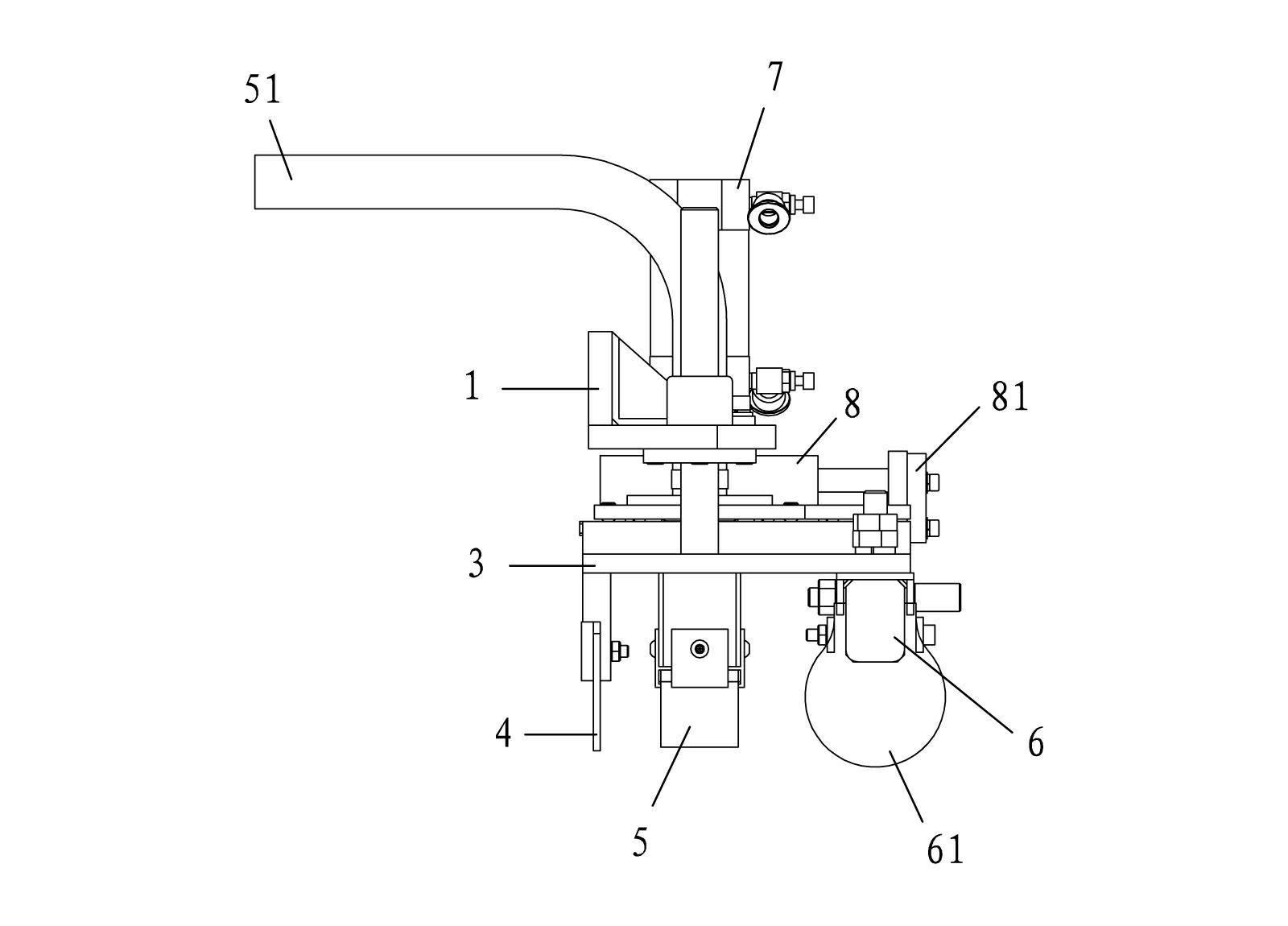

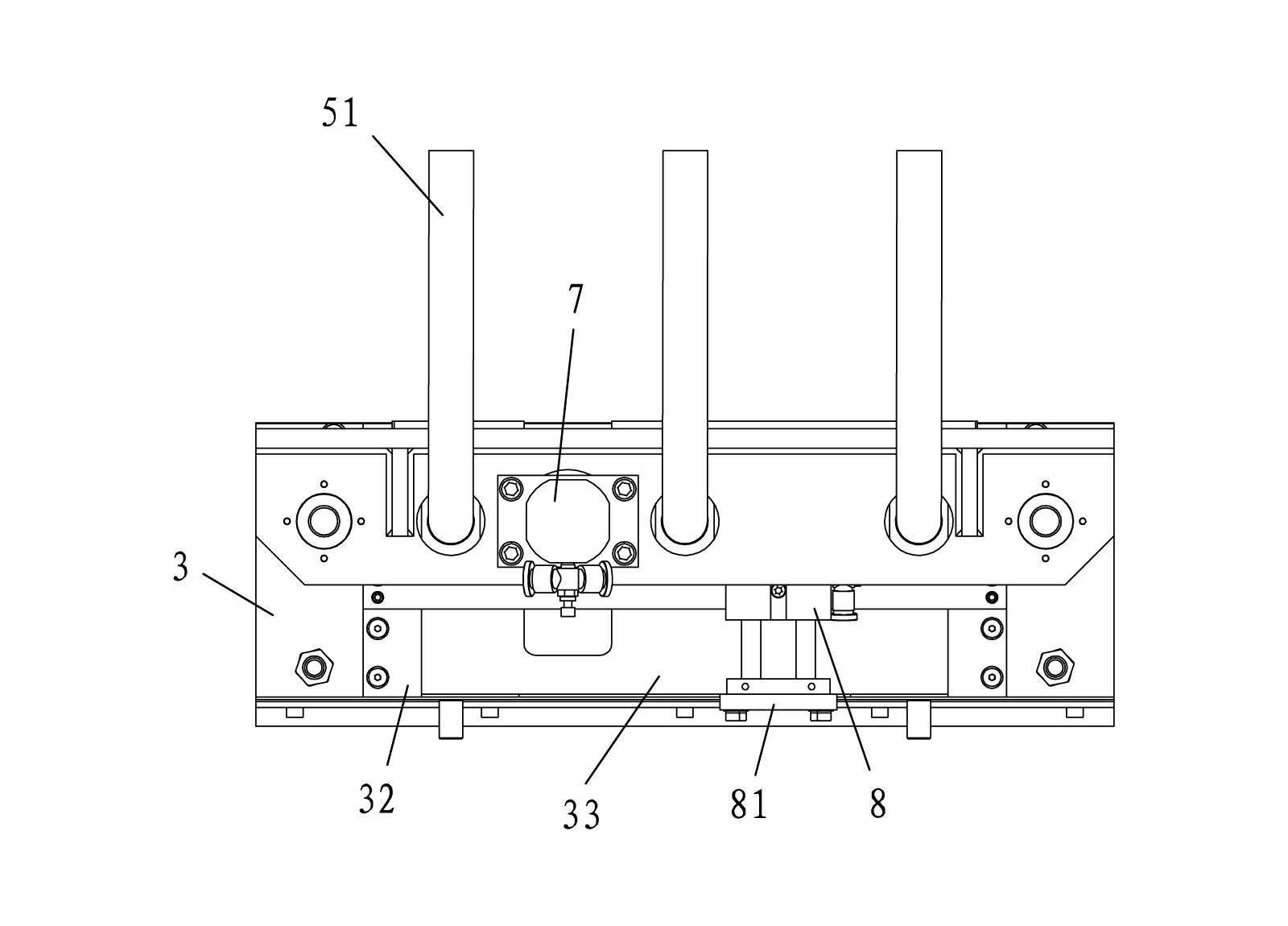

[0017] refer to Figure 1 to Figure 4 , a mold surface cleaning device for permanent magnet ferrite-tile magnet molds of the present invention, including a cleaning fixed seat 1 fixed on the reclaiming trolley, and a cleaning fixed seat 1 that is movably connected with the cleaning fixed seat 1 through bearings 2 Clean the supporting plate 3, the cleaning fixed seat 1 is preferably an L-shaped plate, and several elliptical through holes 11 for connecting the reclaiming trolley are arranged on the vertical surface; the cleaning supporting plate 3 can be lifted along the bearing 2 Movement, the bottom of the cleaning support plate 3 is provided with a scraper 4, a vacuum cleaner seat 5, and a sponge fixing seat 6 sequentially from front to back, and a sponge 61 is installed on the sponge fixing seat 6. Since the mold surface cleaning device of the present invention is fixed on the feeding trolley, when the trolley withdraws after taking the billet, the scraper 4 scrapes loose th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap