Nanometer filter plate forming mould special for filter press and forming method thereof

A technology of nano-filtration and forming molds, which is applied in the field of filter plate forming molds for filter presses. It can solve the problems that nano-filter plates cannot be formed, and achieve good anti-fouling properties, superior acid resistance, and simple and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

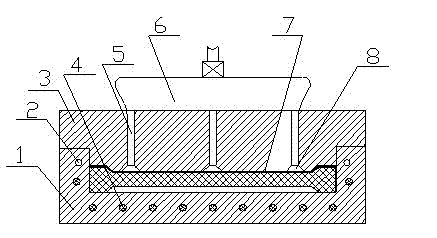

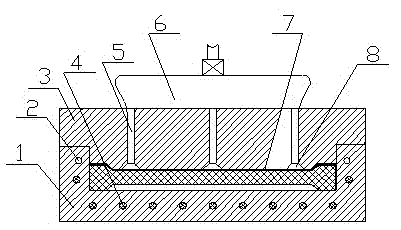

[0009] Embodiment 1: with reference to attached figure 1 . A special nano-filter plate forming mold for filter presses, which includes an upper mold 3 and a lower mold 1. There are multiple heating channels around the lower mold 1 and heating elements 4 are built in the heating channels. The molding surface of the upper mold 3 A plurality of nozzles 8 are provided and the nozzles 8 communicate with the nano pressurizer 6 through the fluid channel 5 in the upper mold 3 body. The manufacture of the upper mold 3 and the lower mold 1 is a prior art, and will not be described here. Nano pressurization (jet) device 6 is prior art, does not describe at this.

[0010] The heating element 4 is an electric heating tube or an electric heating wire, and the installation of the electric heating tube or the electric heating wire and the heating channel in the lower mold 1 and the design of the electric heating tube or the electric heating wire terminal connected to the power control end of...

Embodiment 2

[0013] Embodiment 2: On the basis of embodiment 1, the molding method of the special nano-filter plate molding die for filter press, first the filter plate plate material after forming is placed in the lower membrane 1 after heating, when the filter plate in the lower mold cavity When the plate material has just passed the critical point of melting, start the nano pressurizer 6, and the multiple nozzles 8 on the forming die surface of the upper mold 3 above the lower mold 1 spray the nano material onto the surface of the filter plate material, and then pressurize Close the upper mold 3, force the nano-layer sprayed on the filter plate to merge into the surface of the filter plate to form a nano-layer 7, and obtain the nano-filter plate after cooling. The pressure ejected from the nozzle 8 is greater than or equal to the pressure exerted by the upper die on the filter plate. The nano material is nano ceramic powder, nano metal material. The nanolayer is larger than 0.1 microns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com