Vertical-flow type settling pond

A technology of vertical flow sedimentation tank and tank top, which is applied in the direction of settling tank, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Flushing cycle, good biological treatment effect, strong dirt holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

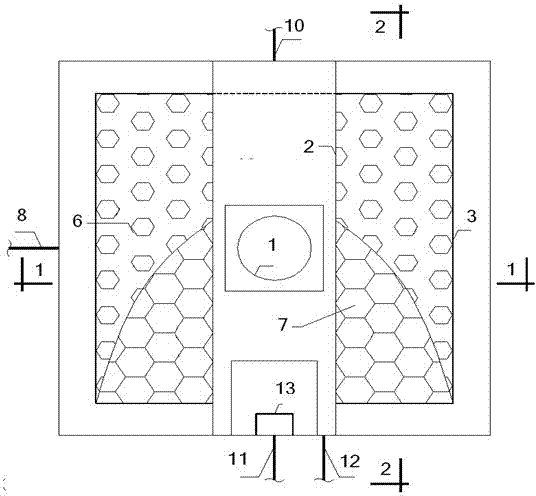

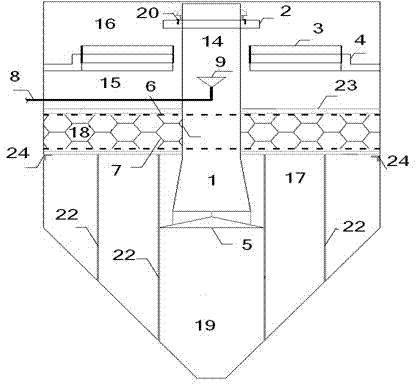

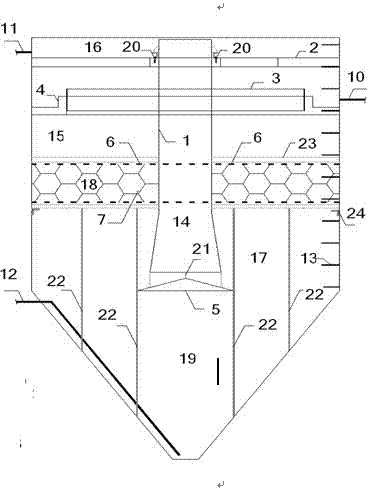

[0034] In the vertical flow sedimentation tank provided by the present invention, the whole tank body is square, and can also be designed as a circle. The vertical flow sedimentation tank includes a water inlet area 14 extending from the top of the pool to the lower part of the pool, the water inlet area 14 is provided with a water inlet pipe 8, and the vertical flow sedimentation tank also includes a circle from top to bottom The overhaul area 16, catchment area 15, filter area 18 and sedimentation area 17 that described water inlet area 14 is provided with, the bottom of described sedimentation area is communicated with mud collecting area 19, is provided with in described water collection area 15 and can according to A water collecting device for adjusting the water level, the water collecting device communicates with the outlet pipe 10 , and the water collecting area 15 also includes a filtered water buffer section arranged at the lower part of the water collecting area 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com