Chemical vapor deposition furnace

A technology of chemical vapor deposition and furnace body, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high labor intensity and high labor cost, and achieve easy disassembly, high output and large volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

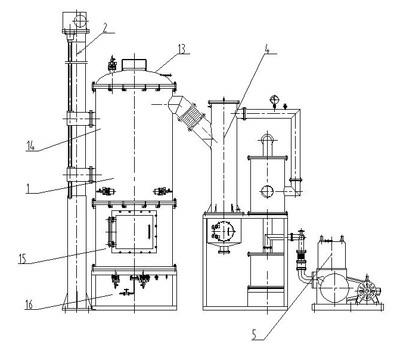

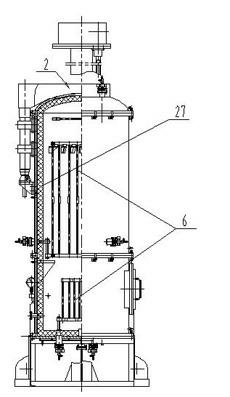

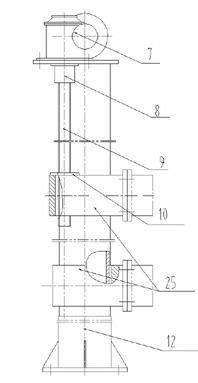

[0021] see figure 1 , 2 , the present invention includes a furnace body 1, a furnace body lifting mechanism 2, a furnace cover lifting mechanism 3, a three-stage filtration system 4, a vacuum system 5, and a heater 6. The heater 6 includes an upper heating body, a middle heating body, and a lower heating body. The heating body, the furnace body 1 adopts a vertical and internal heating structure, including a furnace cover 13, an upper furnace body 14, a lower furnace body 15, and a furnace bottom 16. The upper furnace body 14 and the lower furnace body 15 are cylindrical and double-layer water-cooled structure, the heating body in the lower area is fixed on the bottom of the furnace, and the electrodes are drawn out from the bottom of the furnace; the heating body in the middle area is fixed in the upper furnace body, and the electrodes are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com