High-pressure bidirectional miniature power-driven air pump

An electric air pump and micro technology, applied in the direction of pumps, piston pumps, machines/engines, etc., can solve the problems of limited capacity, large volume and large volume of high-pressure gas cylinders, and achieve good starting performance under pressure, simple and simplified transmission mechanism. The effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

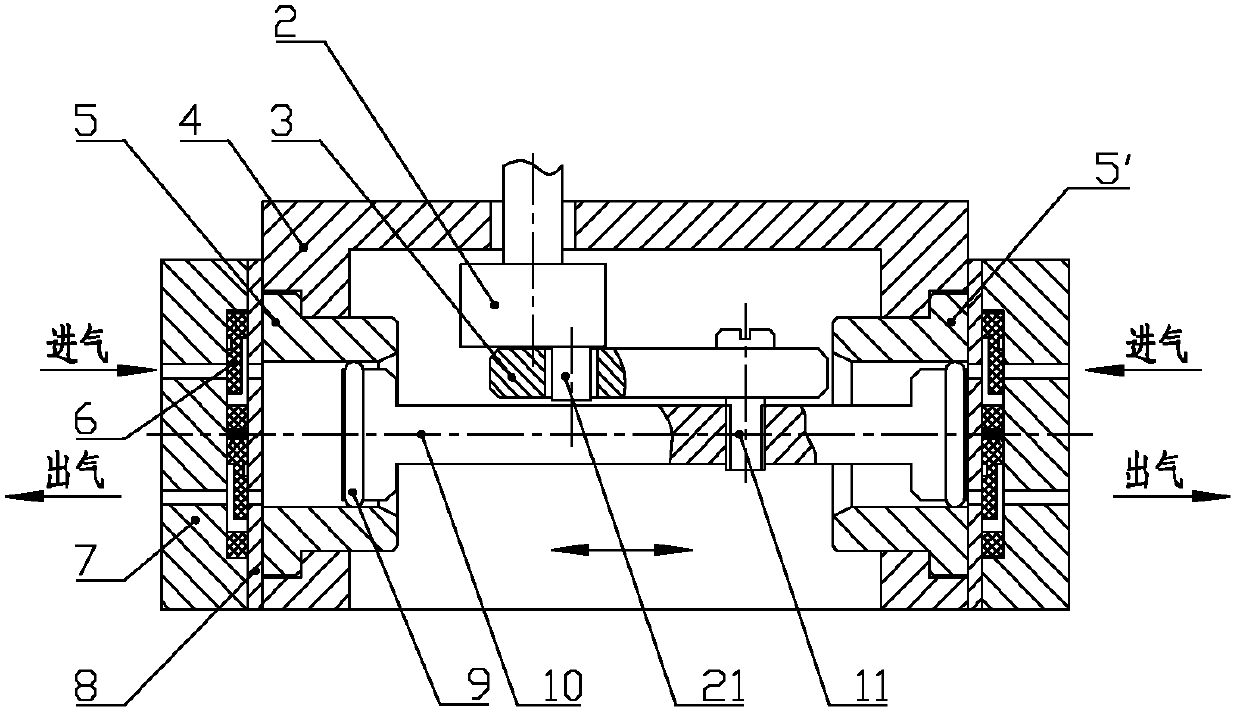

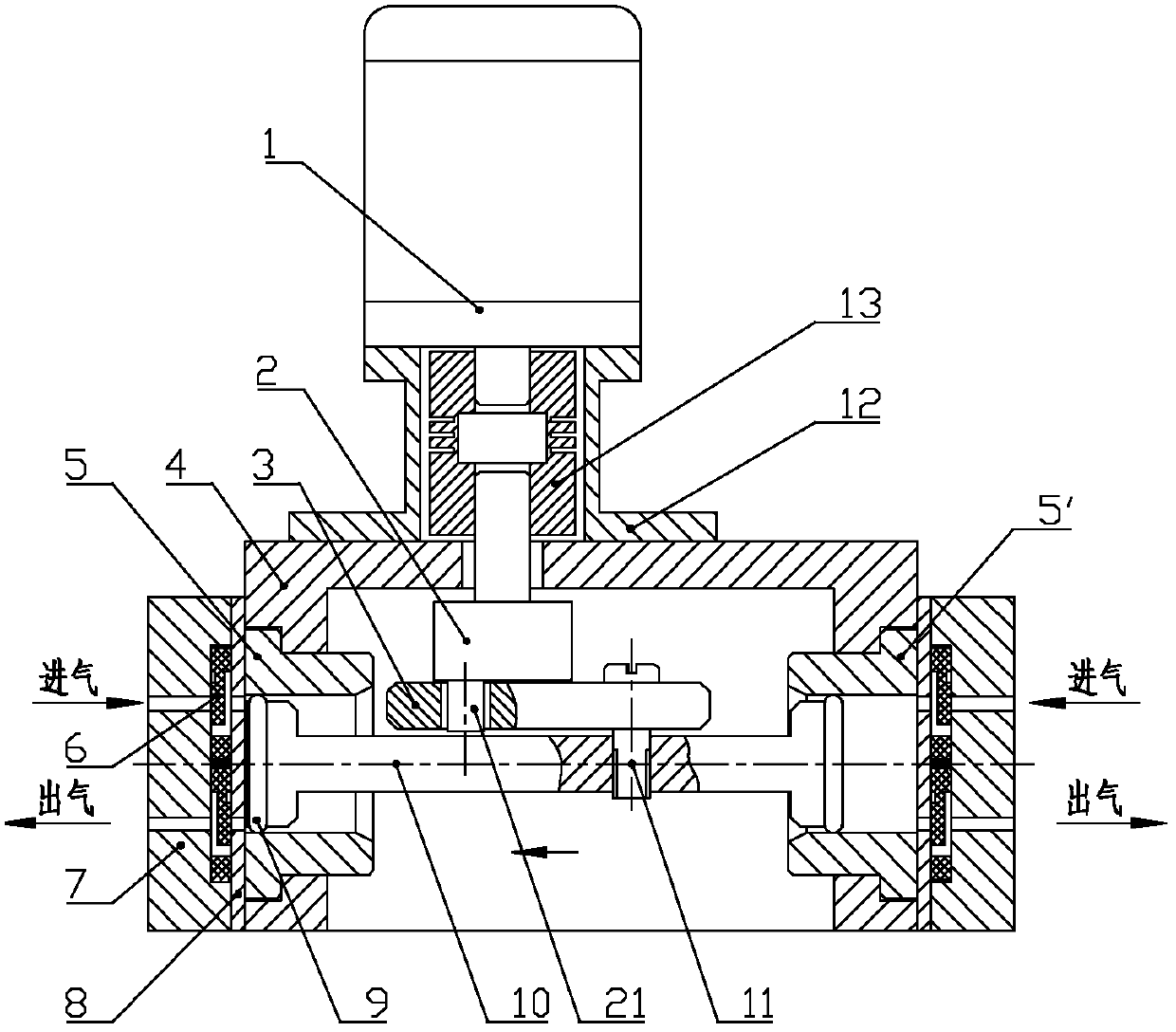

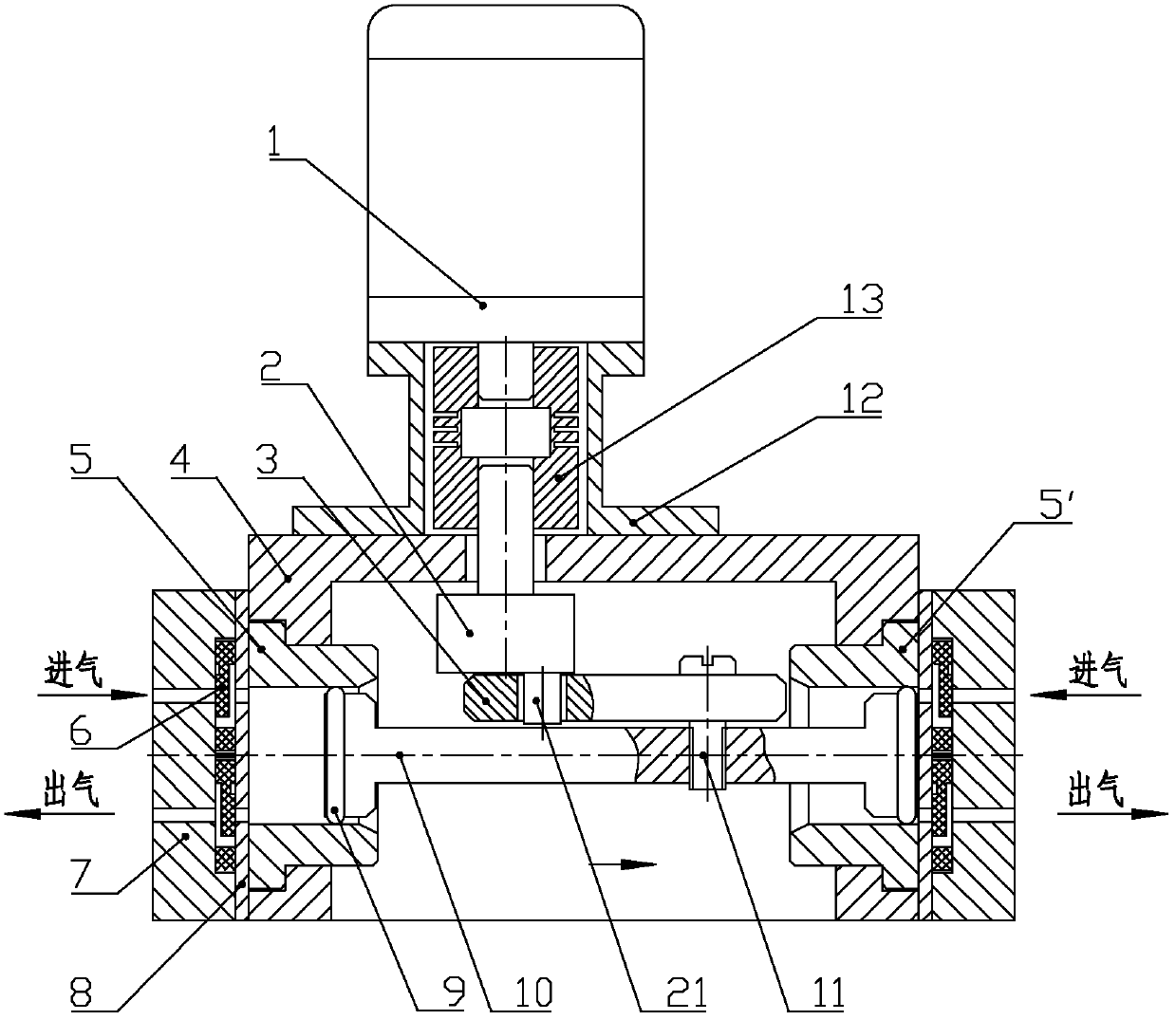

[0014] For the specific structure of the high-pressure bidirectional miniature electric air pump of the present invention, see Figure 1-Figure 3 shown, where figure 1 The main components are shown; figure 2 It shows the limit working position of the left piston in the compression state and the right piston in the suction state; image 3 It shows the limit working position where the right piston is in the compression state and the left piston is in the suction state.

[0015] see Figure 1-Figure 3 , the high-pressure two-way miniature electric air pump of the present invention includes a motor 1, an eccentric shaft 2, a swing rod 3, a pump body 4, a left cylinder body 5 and a right cylinder body 5', a one-way valve body 6, a cylinder head 7, a cylinder Pad 8, sealing ring 9, piston rod 10 and screw 11, motor bracket 12, coupling 13. in:

[0016] Pump body 4 is the connection part of this electric air pump, and motor 1 is fixed on the pump body 4 by motor support 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com