Lamp sealing method

A technology of lamps and sealing rings, which is applied to lighting devices, components of lighting devices, pre-treated surfaces, etc., can solve problems such as poor sealing, weak connection, water leakage of lamps, etc., to achieve a guaranteed sealing effect, not easy to fall off, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

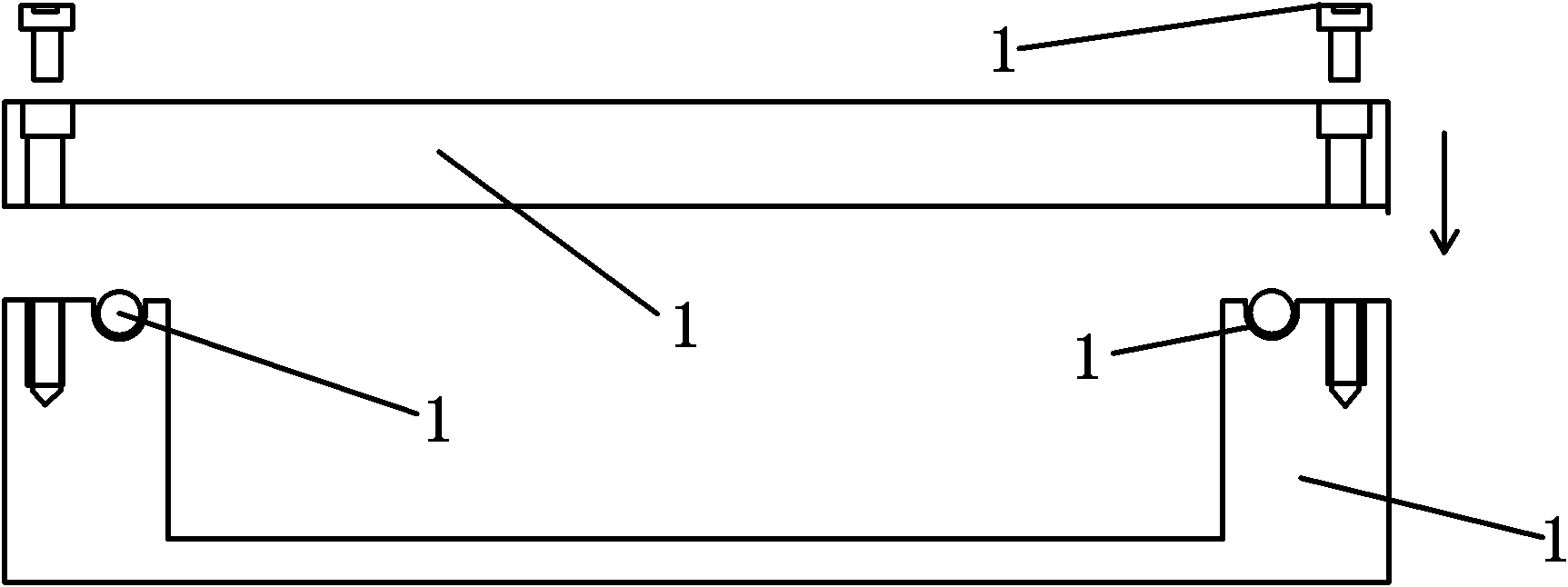

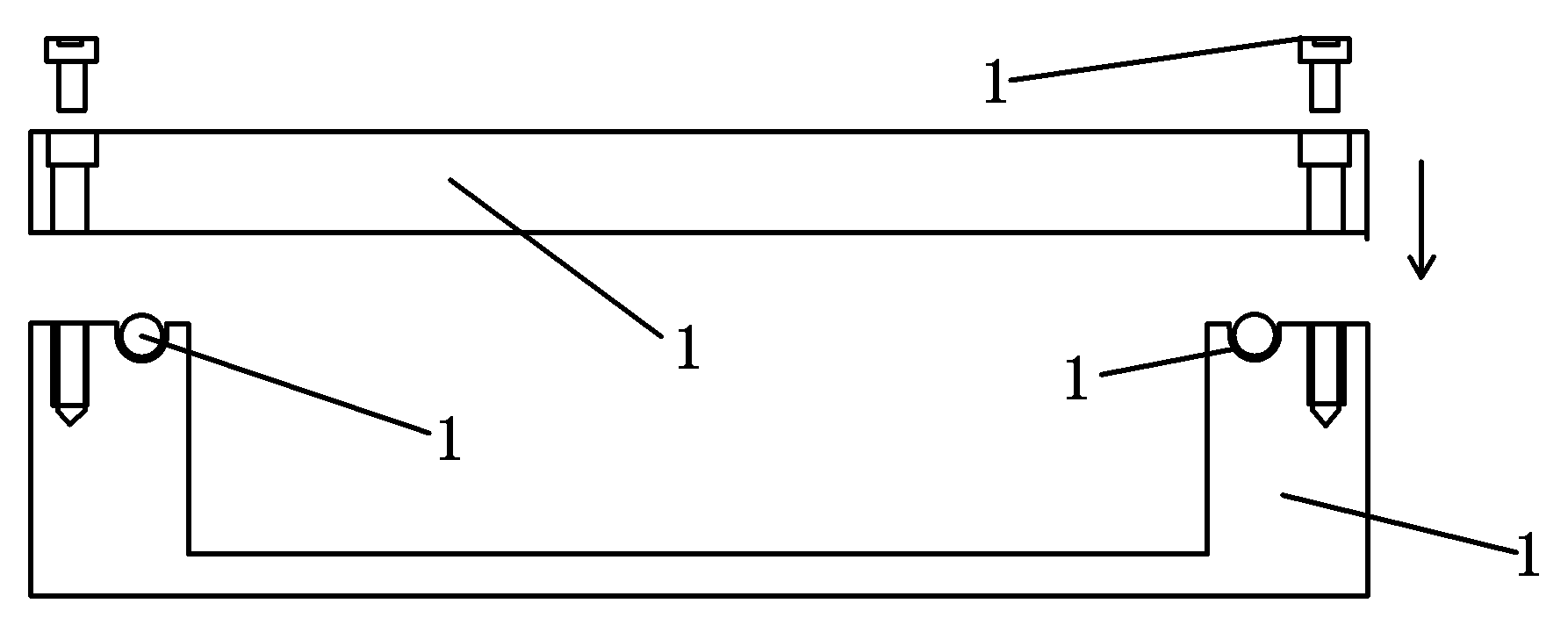

[0011] A lamp sealing method, characterized in that: a groove 2 is set on the base 1 of the lamp, a circle of colloid is injected into the groove 2 by automatic gluing, and a sealing ring 3 without seams is formed after the colloid is cured. Cover the lamp cover plate 4 again, and press it with the screw 5 to achieve the sealing effect. The colloid utilizes surface tension, and the highest point is full of grooves. The colloid is Dow Corning PV-8301 quick-drying glue. Dow Corning PV-8301 (Dow PV-8301Fast CureSealant) quick-drying glue is formed after the main colloid of Dow Corning PV-8300 and Dow Corning PV-8301 catalyst are mixed with the mass ratio of 10 to 1 (that is, in the form of AB glue). , to cure after 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com