Non-contact laser detecting instrument for displaying roughness of steel ball

A non-contact, detector technology, applied in the field of measurement, can solve the problems of high loss of laser light source, difficult movement, large space occupation, etc., to achieve the effect of increasing effective photosensitive ability, high moving accuracy, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

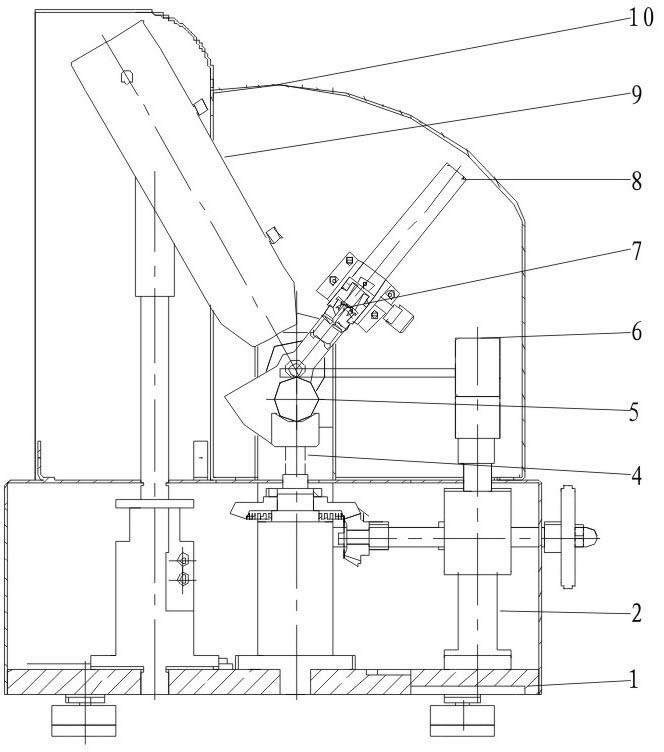

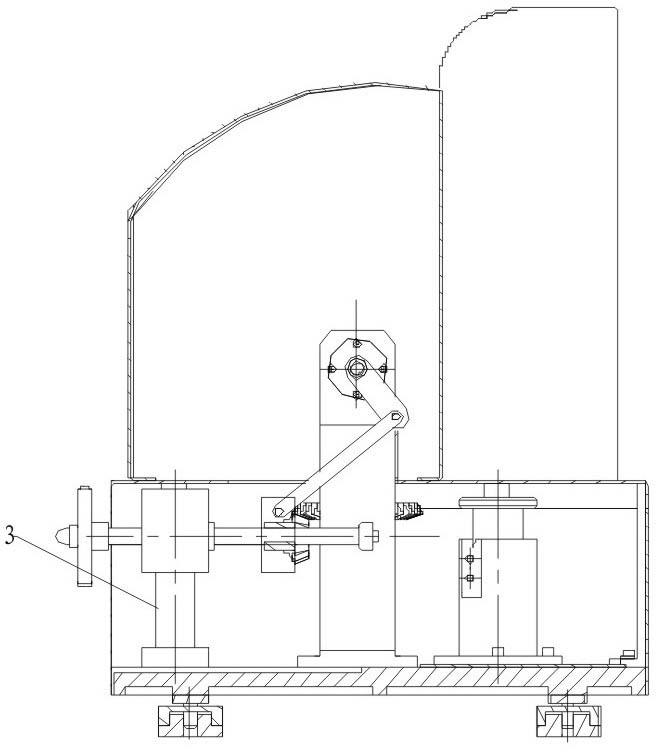

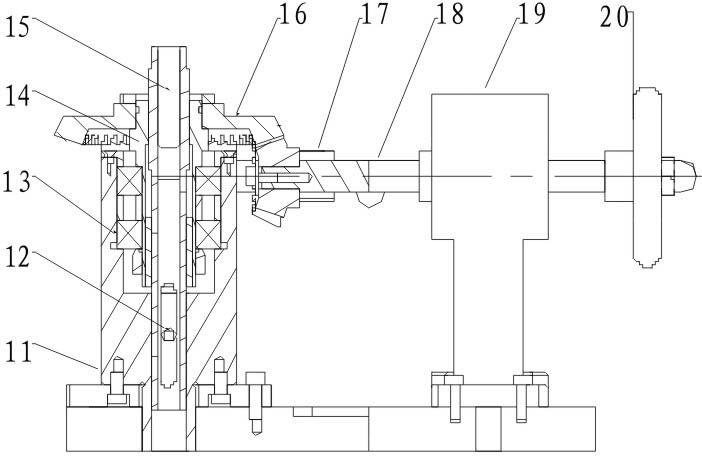

[0033] The detector of the present invention adopts the principle of laser speckle in the measurement principle. The key to the mechanical structure of the detector is to adjust the incident light spot of the laser tube, the top of the steel ball and the center of rotation of the sensor adjustment device to one point, that is, the three points are on the same line. , at the same time, the reflected light spot just falls on the very center of the optical nuclear sensor, and the entire optical path is well protected by a dark room. In this case, the error can be minimized and the measurement standard can be met.

[0034] Such as figure 1 , 2Shown: steel ball adjustment device (2), swing adjustment device (3), laser tube and adjustment device (9) are fixed on the base (1), steel ball adjustment device (2) is fixed in the middle of the base (1), measure The mandrel (4) is installed on the lifting shaft (15) in the steel ball adjustment device (2), and the measured steel ball (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com