Testing system and method for high-efficiency integrated optical fiber gyroscope

A technology of fiber optic gyroscope and test system, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of complex operation and long time, and achieve the effect of short time, providing speed and improving signal processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

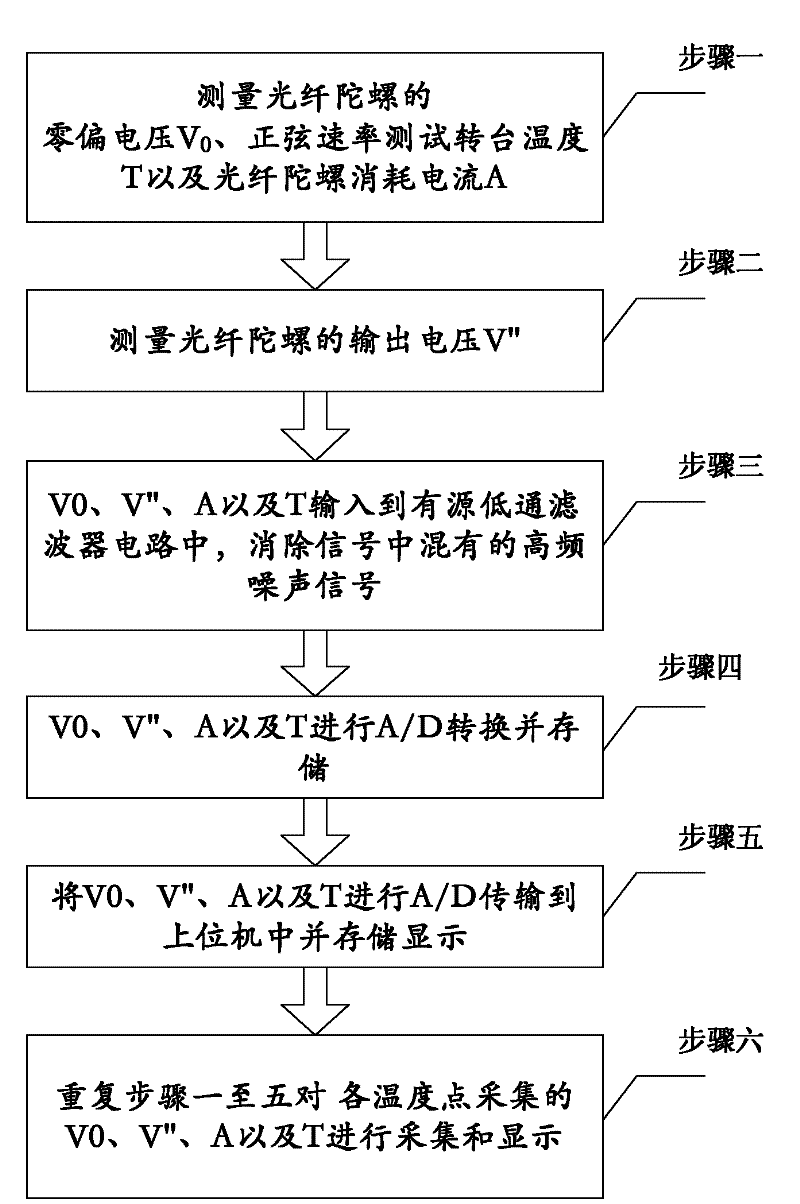

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

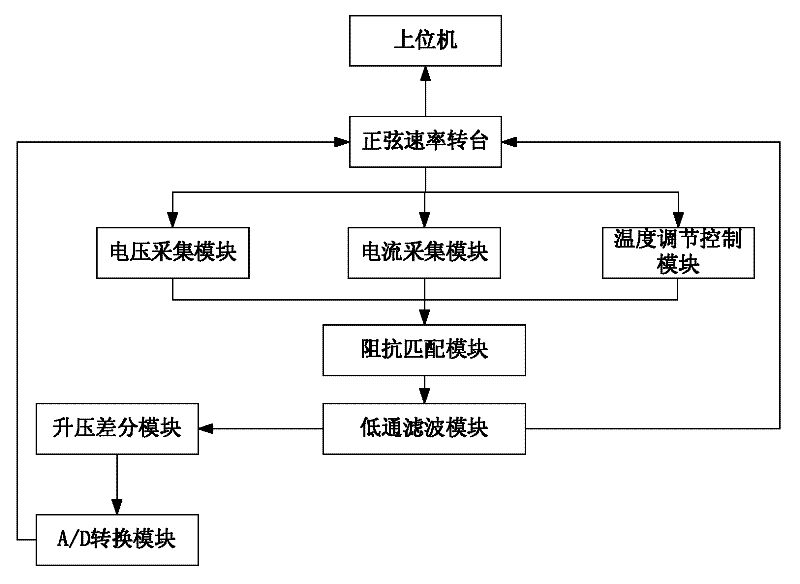

[0030] The high-efficiency integrated fiber optic gyroscope test system of the present invention includes a sine rate turntable, a liquid nitrogen cup, a heating film, a voltage acquisition module, a current acquisition module, a temperature adjustment control module, a low-pass filter module, a boost differential module, and a high-precision A / D Conversion module and upper computer;

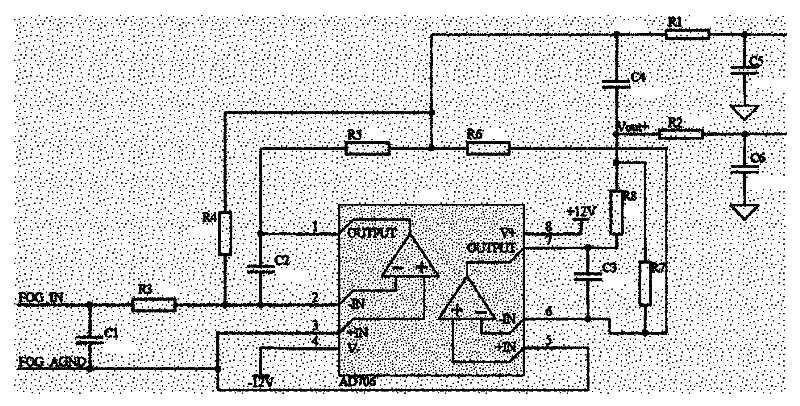

[0031] The sine rate turntable is used to provide a sine rate for the fiber optic gyroscope, including a built-in A / D converter and a memory, wherein the A / D converter and the memory are all located in the main control chip inside the sine rate turntable, and the main control chip is used for To receive the command of the host computer, realize the control of the sine rate turntable; the heating film is located at the bottom of the sine rate test turntable, and the liquid ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com