Efficient coupling energy taking based high-voltage TSC driving device

A technology for coupling energy harvesting and driving devices, applied in flexible AC transmission systems, reactive power adjustment/elimination/compensation, etc., can solve problems such as poor isolation strength and poor anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

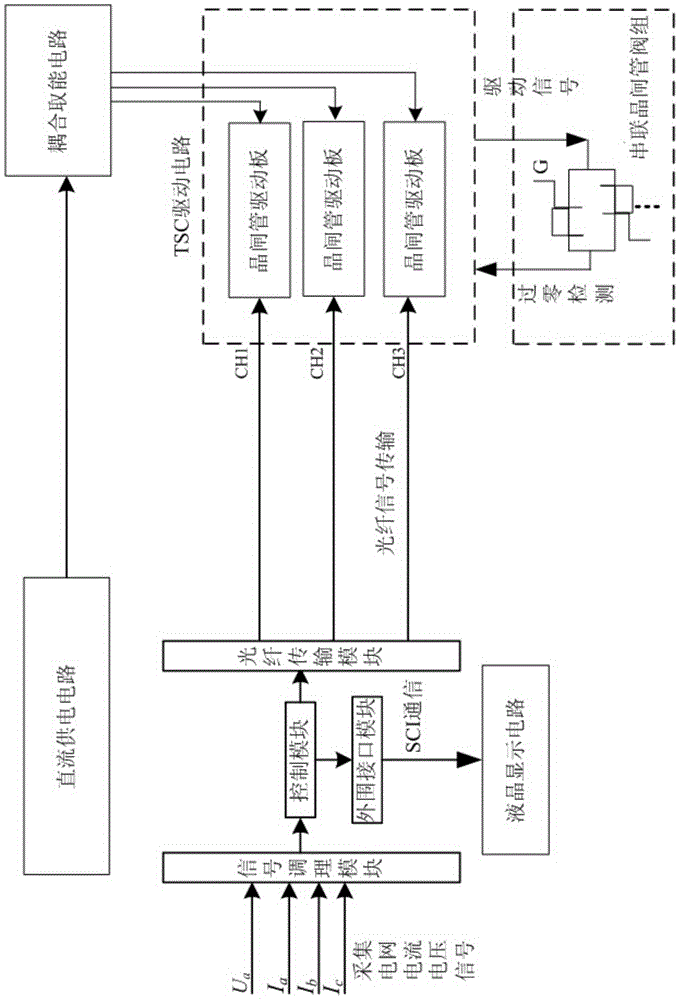

[0043] Specific embodiment one: combination figure 1 To explain this embodiment, the high-voltage TSC driving device based on high-efficiency coupling and energy extraction described in this embodiment includes a signal conditioning module, a control module, an optical fiber transmission module, a DC power supply circuit, a coupling energy extraction circuit, and a TSC driving circuit. ;

[0044] The three-phase voltage and three-phase current on the load side of the distribution network are input to the signal conditioning module. The voltage and current signal output terminal of the signal conditioning module is connected to the voltage and current signal input terminal of the control module. The switching signal output terminal of the control module is connected to the optical fiber transmission. The switching signal input end of the module is connected, and the switching signal output end of the optical fiber transmission module is connected to the switching signal input end o...

specific Embodiment approach 2

[0055] Specific implementation manner two: combination image 3 To explain this embodiment, this embodiment is a further limitation of the high-voltage TSC drive device based on high-efficiency coupling and energy extraction described in the first embodiment. The coupling energy circuit includes a plurality of power boards, and the high-frequency current output terminal of the DC power supply circuit At the same time, it is connected to the high-frequency current input terminals of multiple power boards, and each power board provides working power for a thyristor drive board of a TSC drive circuit;

[0056] The power board includes pulse generator, pulse transformer, high frequency rectifier bridge and power conversion circuit;

[0057] The pulse generator outputs a continuous pulse signal to the pulse transformer. The transformer pulse transformer couples the input pulse signal to the high-frequency rectifier bridge. After the high-frequency rectifier bridge is rectified, the pulse...

specific Embodiment approach 3

[0061] Specific implementation mode 3: This implementation mode further defines the high-voltage TSC drive device based on high-efficiency coupling and energy extraction described in specific implementation mode 1. The working process of the control module outputting switching signals includes the following steps:

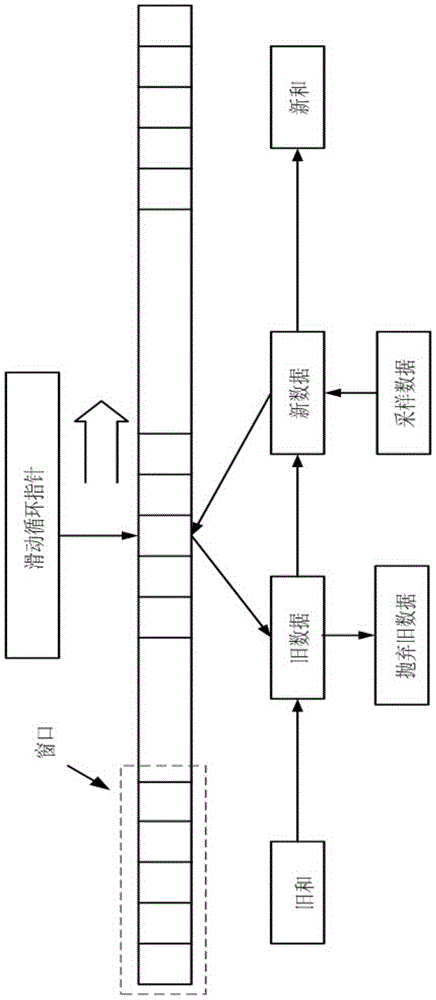

[0062] Step 1: Perform sliding window iterative Fourier transform on the conditioned voltage and current signals to obtain the fundamental wave of the three-phase voltage and three-phase current and the amplitude and phase of each harmonic, and then obtain the real-time active power according to the reactive power theory And reactive power;

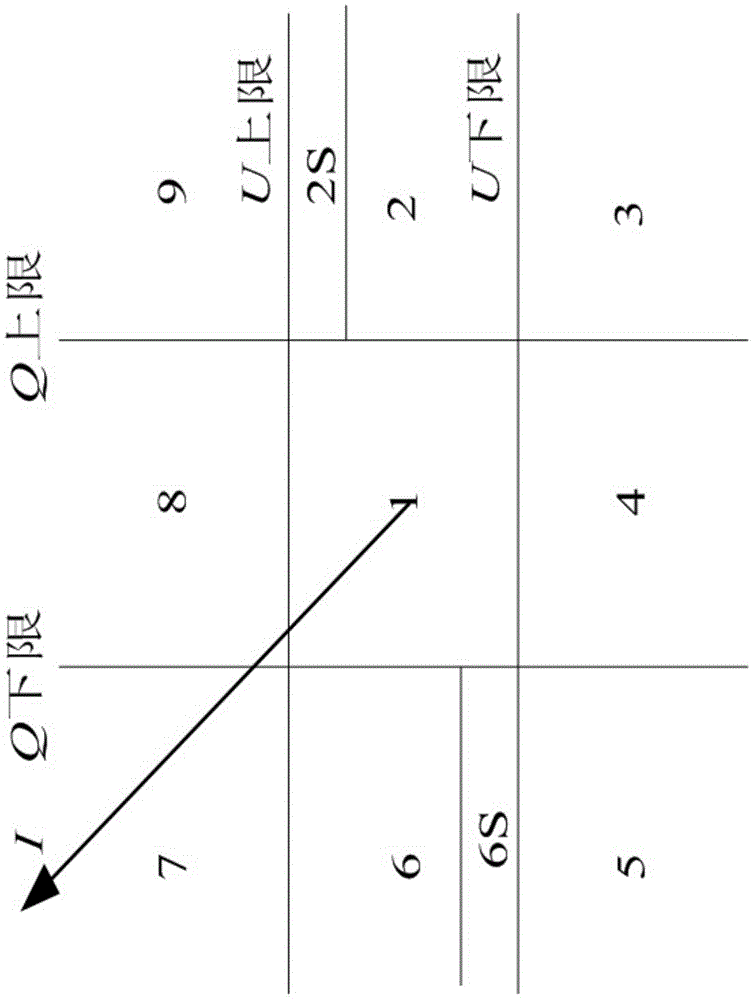

[0063] Step 2: Determine the reactive power and three-phase voltage through the nine-domain method to obtain the switching signal.

[0064] According to the theory of instantaneous reactive power, it is necessary to extract the fundamental wave of the a-phase voltage and other sub-harmonic signals. Compared with the traditional phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com