Micro channel flat pipe mould for horizontal type hot-extrusion

A technology of hot extrusion and micro-channel, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult forming of precision micro-channel flat tubes, small extrusion force and extrusion ratio, and poor compactness of the product structure, and achieve uniform wall thickness. The effect of good density, complex shape and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

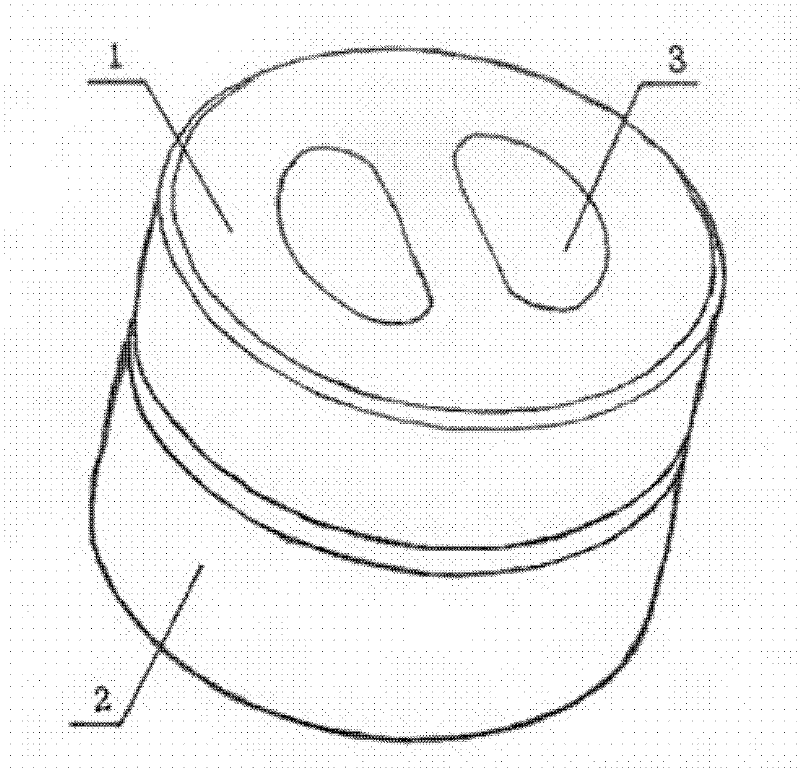

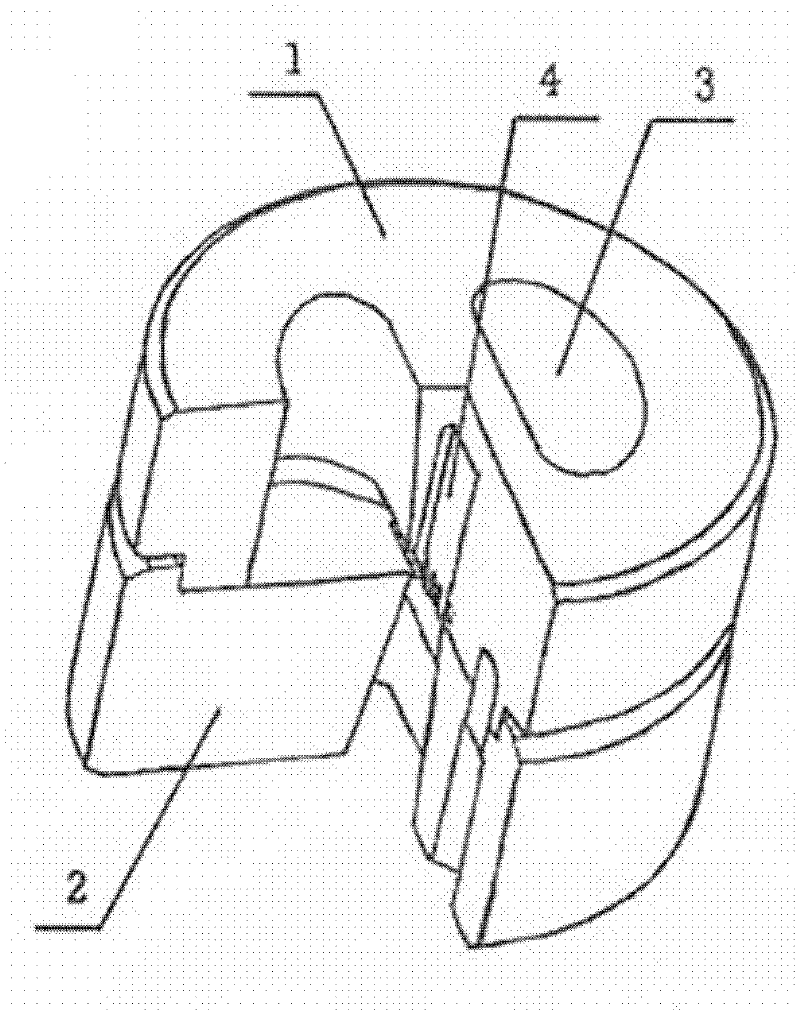

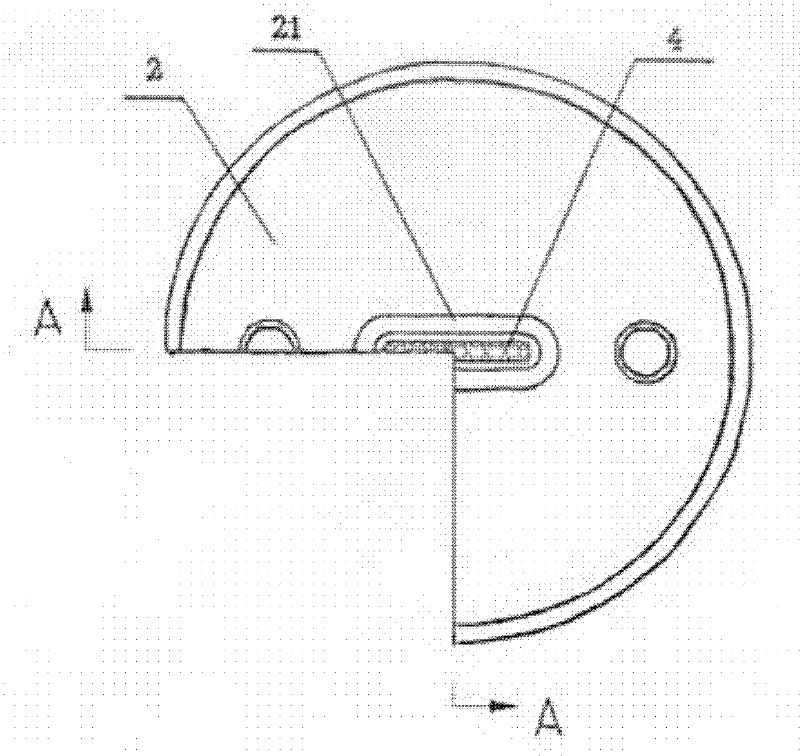

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a microchannel flat tube die for horizontal hot extrusion includes an upper die 1 and a lower die 2, the upper die 1 and the lower die 2 are closely matched, and the upper die 1 is provided with two symmetrical Split hole 3, one side of the split hole 3 is a straight edge, the other side is a circular arc, the straight sides of the two split holes 3 face each other; the middle part of the two split holes 3 in the upper mold 1 is provided with an upper mold core groove, and the upper mold core A mold core 4 is inserted in the mold core groove, and a welding chamber 12 is provided at the position corresponding to the split hole 3 at the bottom of the upper mold 1; The mold core 4 can be concentrically matched with the lower mold core 21; the end of the upper mold core 4 is provided with a plurality of equidistant mold pins 41 side by side.

[0012] Using the horizontal hot extrusion method, the aluminum mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com