Process for manufacturing dumbbell and barbell products

A manufacturing process, dumbbell technology, applied in the field of bar and dumbbell products manufacturing process, can solve the problems of high production cost, high energy consumption, high scrap rate, etc., and achieve moderate cost and density, high product qualification rate, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

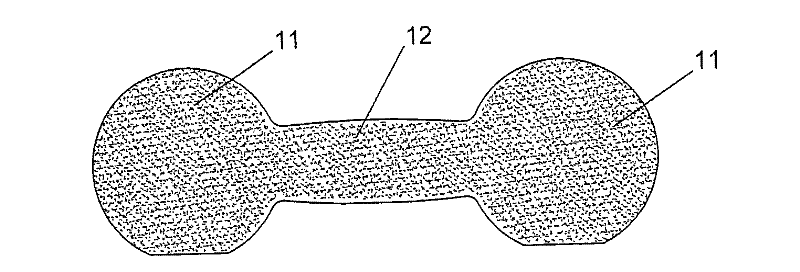

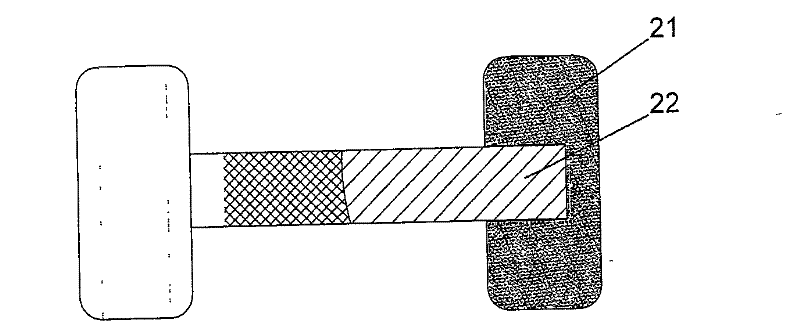

[0032] Such as figure 1 Shown is a kind of integral dumbbell, and the dumbbell head 11 and the dumbbell handle 12 are an integral body, which is formed by pressing a mixed material of mixed iron powder and binder. Of course, the dumbbell head and the dumbbell handle can be molded separately, such as figure 2 , the handle 22 is first prepared, and then pressed into shape with the dumbbell head 21, and the dumbbell head 21 is pressed into shape from a mixed material of mixed iron powder and binder; figure 2 Shown is a dumbbell which may also be a barbell. Such as figure 1 As shown, if the dumbbell head 11 and the dumbbell handle 12 are made into the same size, or the cylindrical shape has just become a kind of weight bar.

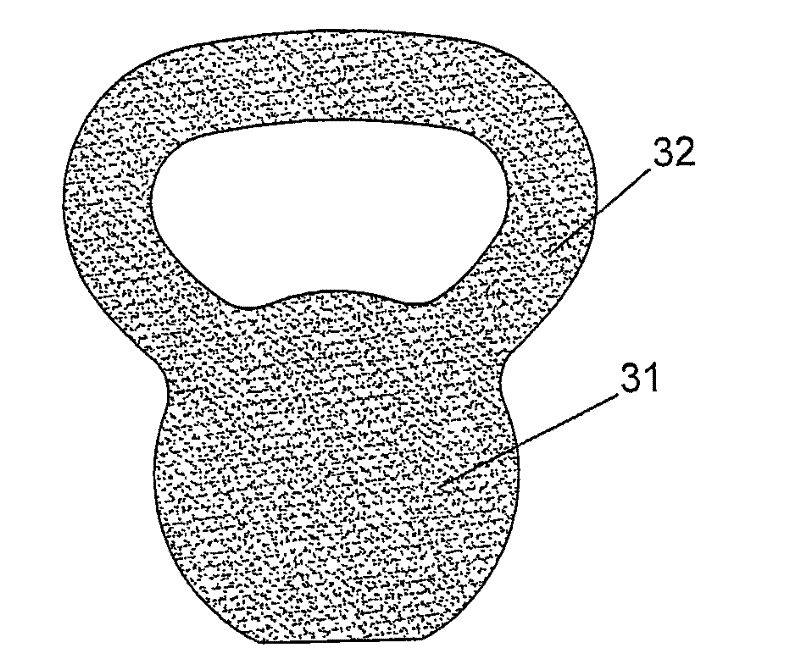

[0033] Such as image 3 Shown is a kettlebell, the kettlebell head 31 and the kettlebell handle 32 are integral, and are formed by pressing a mixed material of mixed iron powder and binder. according to figure 2 Of course, the kettlebell head 31 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com