Automatic welding connector device

An automatic welding and connector technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing quality and efficiency, insufficient precision, time-consuming, etc., and achieve the effect of improving welding efficiency and high welding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

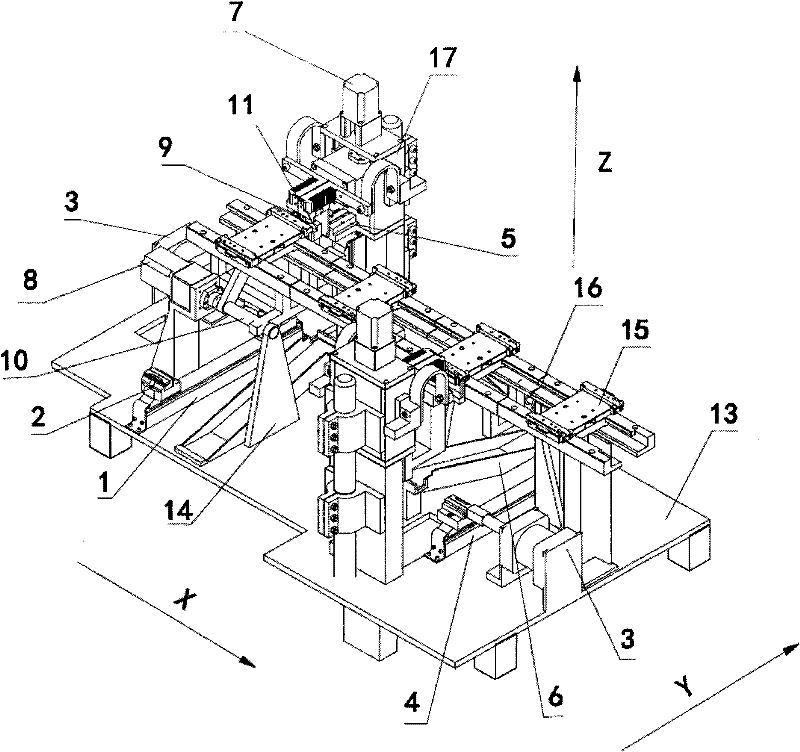

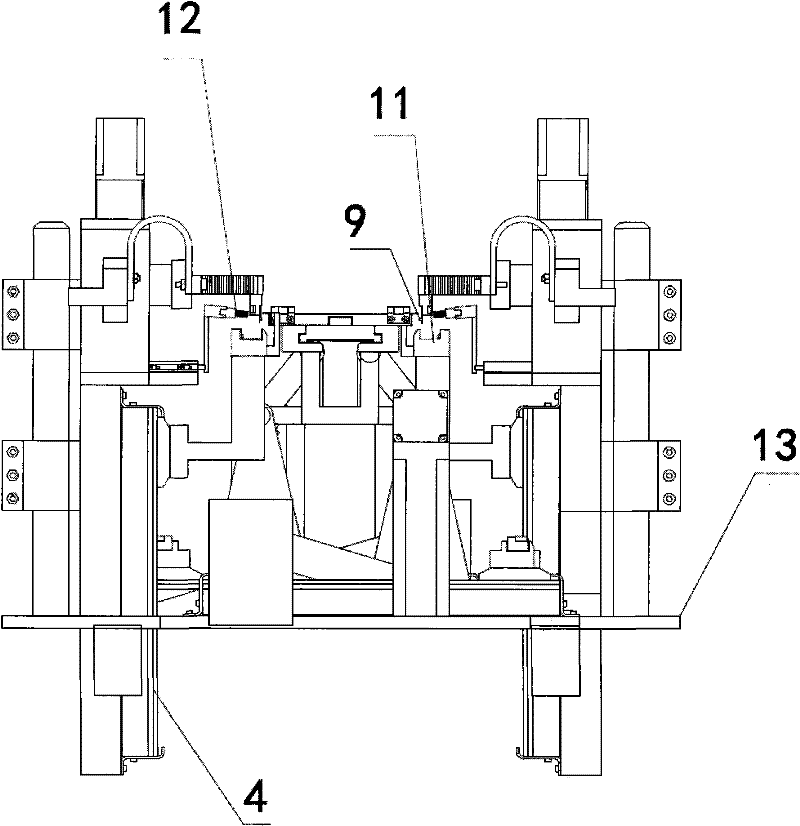

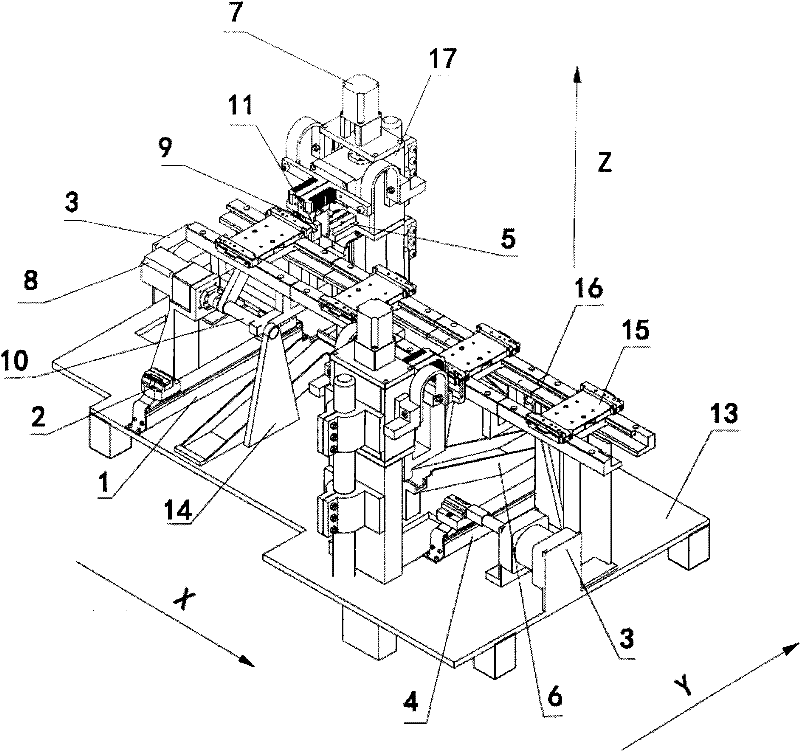

[0019] like Figure 1-2 The shown automatic welding connector device includes a workbench 13. Two supports 14 are arranged on the workbench 13. A rotating shaft 10 is pivotally connected to the two supports 14. A first servo motor 8 is connected to one end of the rotating shaft 10. The first servo motor 8 can drive the rotating shaft 10 to rotate. A strip-shaped transmission track 15 is also erected on the workbench 13, and the transmission track 15 is connected to the rotating shaft 10. By rotating the rotating shaft 10, the transmission track 15 can be driven together. Rotating, at least one carrier 16 for loading core wires to be welded is slidably connected to the transmission track 15 .

[0020] On the workbench 13, both sides of the transmission track 15 are alternately provided with two welding assemblies and two second transmission assemblies, the welding assembly includes a frame 17 arranged on the workbench 13, and a second Servo motor 7, a welding head 9 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com