Method and improved device for argonoxygen refining of low-carbon ferrochrome

An argon-oxygen refining and low-carbon chromium technology is applied in the field of refining high-carbon ferrochromium alloys into low-carbon ferrochromium alloys, and can solve the problems of carbon reduction difficulties, increased difficulty of chromium oxide reduction, and increased refining costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

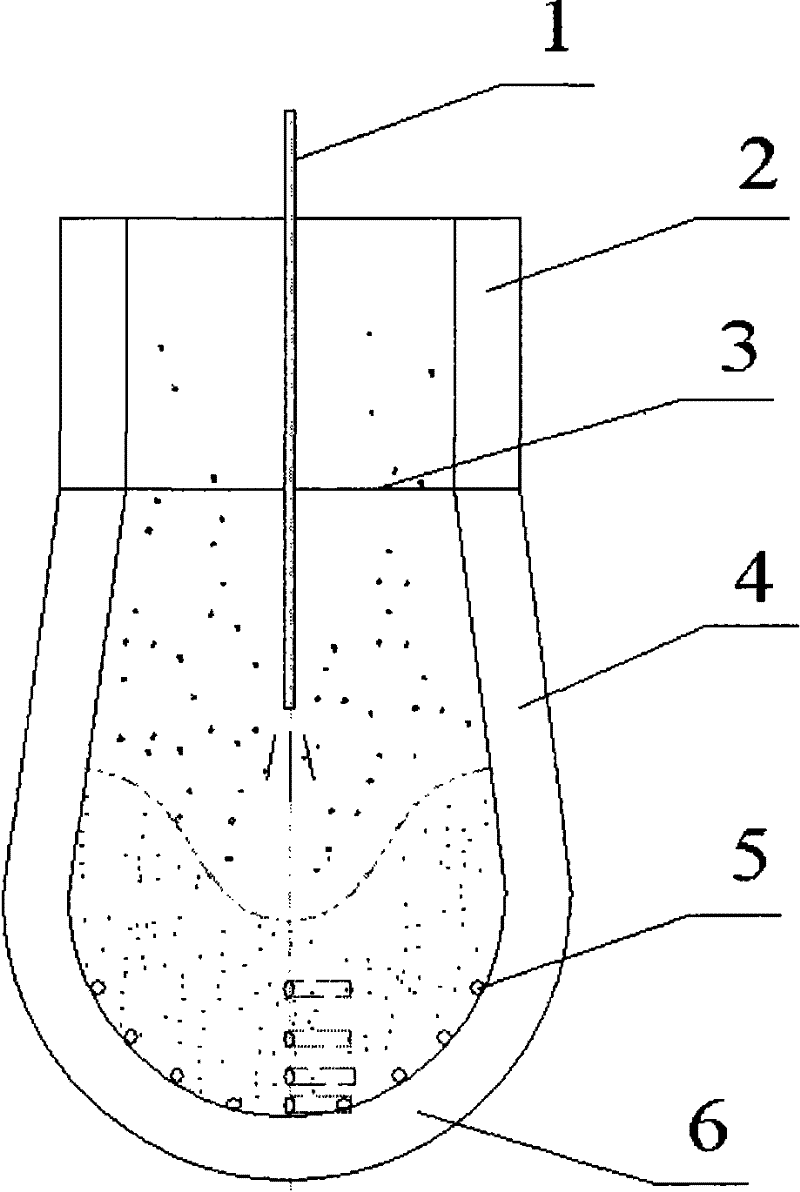

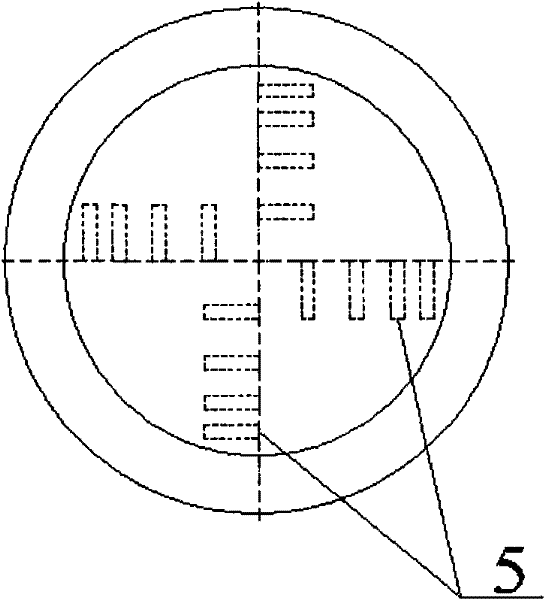

[0058] In the experiment, a top-bottom double-blown converter with a production capacity of 5 tons was used as the refining furnace. The top lance 1 was composed of 3 water-cooled nozzles arranged in a triangle; Auxiliary furnace body 2 with a height of 1.5 meters can be removed; an exhaust channel that can move up and down is installed above the auxiliary furnace body 2. Pa (Pa) exhaust fan.

[0059] 4 tons of carbon content (wt.%) is 8.2%, chromium content (wt.%) is 70% primary smelt to transfer in the converter, measure its temperature to be 1575 ℃, add 35 kilograms of light calcined calcium oxide powder and Add 1.5 kg of iron oxide and 1.5 kg of manganese oxide, then top and bottom blowing argon (nitrogen) / oxygen to start pre-oxidation of the melt.

[0060] Start the top-blowing argon (nitrogen) / oxygen, first set the top-blowing flow rate to 8.0 cubic meters per minute, the top-blowing argon (nitrogen) / oxygen mixing ratio to 6:4, and set the height between the nozzle of t...

Embodiment 2

[0070] Still using the above-mentioned 5 tons of top and bottom double-blown converters, 4 tons of carbon content (wt.%) is 7.9%, chromium content (wt.%) is 68% of the primary smelt into the converter, and its temperature is measured as 1570°C, after adding 20 kg of lightly burned calcium oxide powder, start blowing argon (nitrogen) / oxygen at the top and bottom again, set the flow rate of top blowing to 6.0 cubic meters per minute, and the mixing ratio of top blowing argon (nitrogen) / oxygen to 5: 5. The height of the nozzle of the top lance from the still liquid level of the melt is set to 0.25 meters, the flow rate of the bottom blowing is set to 1.8 cubic meters per minute, and the mixing ratio of the bottom blowing argon (nitrogen) / oxygen is 3:7.

[0071] After 20 minutes, the melt temperature was measured to be 1680°C, the top blowing flow rate was adjusted to 9.5 cubic meters per minute, the top blowing argon (nitrogen) / oxygen mixing ratio was adjusted to 3:7, and the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com