Yarn breakage alarm device of yarn pretension regulating mechanism of computer-based flat knitting machine

A technology for adjusting mechanisms and alarm devices, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as relapse and increase labor intensity of workers, and achieve the effect of ensuring reliability and avoiding increased work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

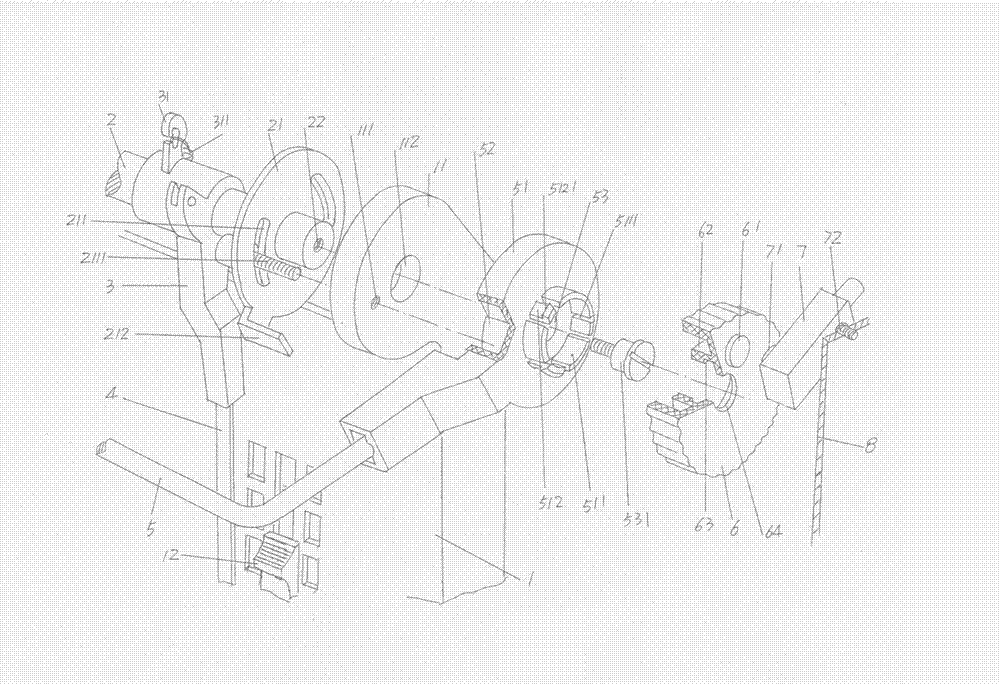

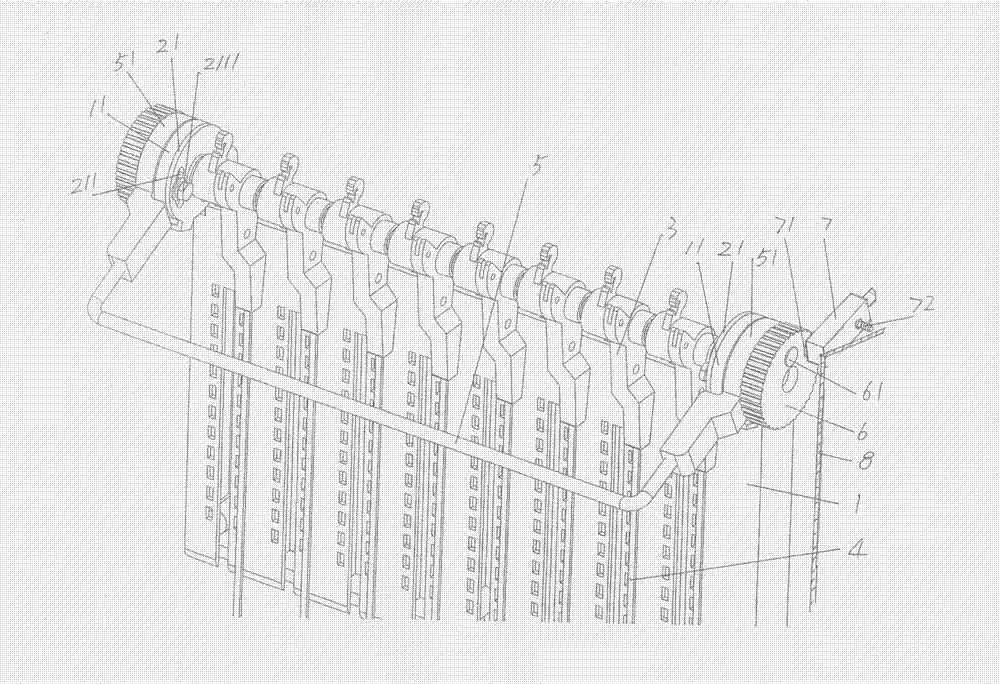

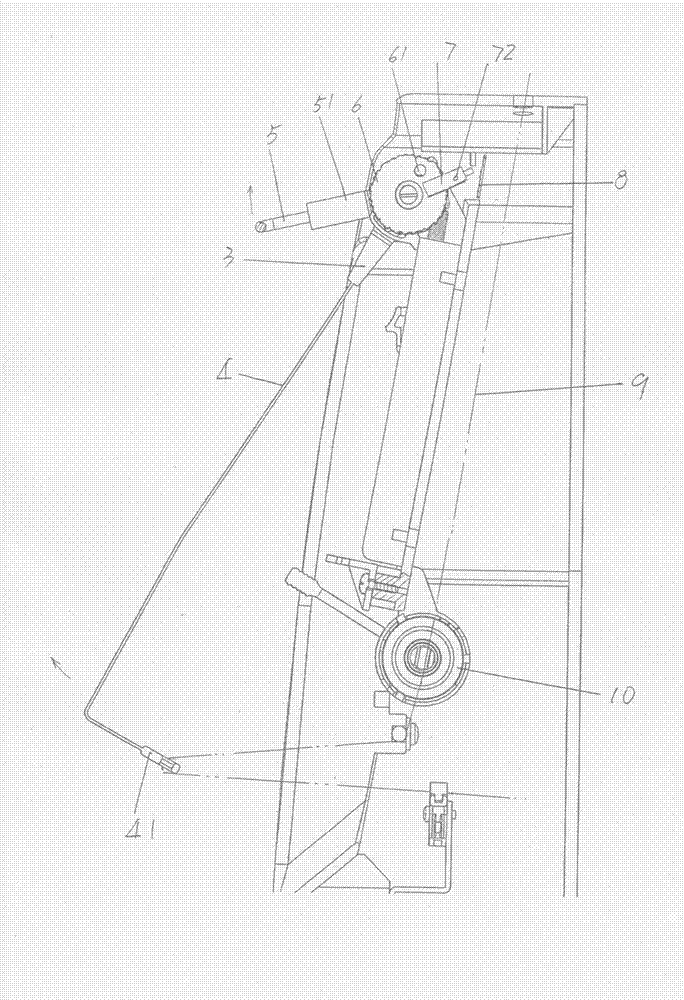

[0022] please see figure 1 , the yarn pretension adjustment mechanism of the computerized flat knitting machine is given. The yarn pretension adjustment mechanism includes a base plate 1, a fixed shaft 2, a set of yarn guide arms 3 and a set of yarn guide arms 3 equal in number to The yarn guide rod 4 and the two ends of the substrate 1 facing the fixed shaft 1 each extend with a fixed ear 11, the fixed ear 11 is fixed to the fixed shaft 2 through the fixed ear hole 112 thereon, and the body of the substrate 1 is movable. There is a group of tension spring tension adjustment sliders 12 (8 in this embodiment), one end of a group of yarn guide arms 3, that is, the base, is rotatably sleeved on the fixed shaft 2, and the ends of each yarn guide arm 3, that is, the base An extension spring hanging foot 31 is extended, one end of an extension spring 311 is fixed on the extension spring hanging foot 31, and the other end of the extension spring 311 corresponds to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com