Fogging surface silky wax feel finishing agent for synthetic leather and preparation method thereof

A technology of synthetic leather and treatment agent, applied in fiber treatment, textile and papermaking, etc., can solve problems such as difficulty, and achieve the effects of simple process, increased cost, and good matte matte effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

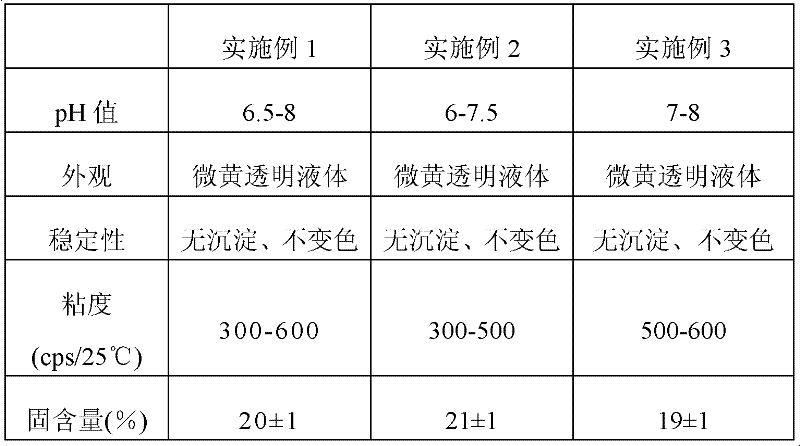

Embodiment 1

[0022] The matte silky waxy feeling treatment agent for synthetic leather consists of 40 parts by weight of modified polyurethane resin, 20 parts by weight of DMF, 20 parts by weight of butyl acetate, 4 parts by weight of silica matting powder, and 2 parts by weight of modified aminosiloxane , 2 parts by weight of dimethyl silicone oil, 3 parts by weight of erucamide, 3 parts by weight of polyurethane color beads, and 1 part by weight of silicone leveling agent.

[0023] The preparation method of the above-mentioned matte silky waxy feeling treatment agent for synthetic leather is: under normal temperature and pressure, 10 parts by weight of modified polyurethane resin, 20 parts by weight of DMF, 20 parts by weight of butyl acetate and 4 parts by weight of silicon dioxide Mix the matting powder thoroughly, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 2 parts by weight of modified aminosiloxane, 2 parts by weight of dimethyl silicone oil, ...

Embodiment 2

[0026] The matte silky waxy feeling treatment agent for synthetic leather consists of 30 parts by weight of modified polyurethane resin, 30 parts by weight of DMF, 30 parts by weight of butyl acetate, 5 parts by weight of silica matting powder, and 1 part by weight of modified aminosiloxane , 3 parts by weight of dimethyl silicone oil, 1 part by weight of erucamide, 5 parts by weight of polyurethane color beads, and 2 parts by weight of silicone leveling agent.

[0027] The preparation method of the above-mentioned matte silky waxy feeling treatment agent for synthetic leather is: under normal temperature and pressure, 12 parts by weight of modified polyurethane resin, 30 parts by weight of DMF, 30 parts by weight of butyl acetate and 5 parts by weight of silicon dioxide Mix the matting powder thoroughly, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 1 part by weight of modified aminosiloxane, 3 parts by weight of dimethyl silicone oil, 1 ...

Embodiment 3

[0030] The matte silky waxy feeling treatment agent for synthetic leather consists of 35 parts by weight of modified polyurethane resin, 25 parts by weight of DMF, 25 parts by weight of butyl acetate, 4.5 parts by weight of silica matting powder, and 4 parts by weight of modified aminosiloxane , 1 weight part of dimethyl silicone oil, 2 weight parts of erucamide, 4 weight parts of polyurethane color beads, and 1.5 weight parts of silicone leveling agent.

[0031] The preparation method of the above-mentioned matte silky waxy feeling treatment agent for synthetic leather is: under normal temperature and pressure, 20 parts by weight of modified polyurethane resin, 25 parts by weight of DMF, 25 parts by weight of butyl acetate and 4.5 parts by weight of silicon dioxide Mix the matting powder thoroughly, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 4 parts by weight of modified aminosiloxane, 1 part by weight of dimethyl silicone oil, 2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com