Redundant pitch system

A technology of pitch system and pitch drive, which is applied in the control of wind turbines, engine functions, engines, etc., which can solve the problems of insufficient redundancy and achieve reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

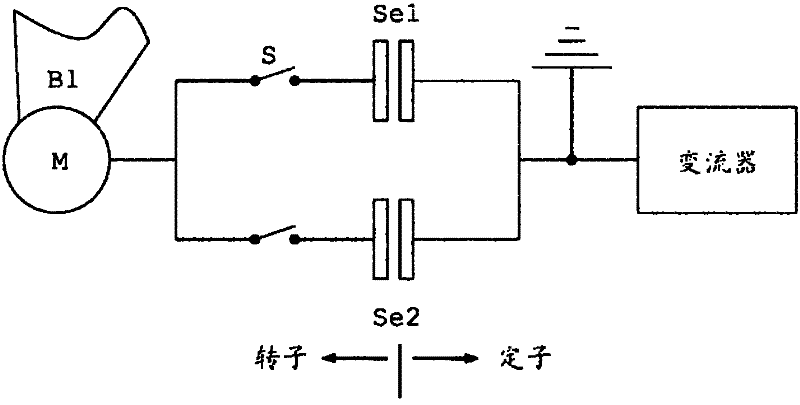

[0041] Depend on Figure 1a It can be seen that the pitch drive of the pitch system according to the first embodiment of the present invention, wherein the motor M mechanically coupled with the rotor blade B1 can pass through a first series circuit composed of a switch S and a first conductive slip ring Se1 Electrically connected to a converter. The motor M can also be electrically connected to the converter through a second series circuit composed of a switch and a second conductive slip ring Se2, wherein the second series circuit is connected in parallel with the first series circuit. Therefore, the motor M can be electrically connected to the converter through the first conductive slip ring Se1 or through the second conductive slip ring Se2 by means of the switch. The conductive slip rings Se1 and Se2 are preferably each designed as a slip ring unit. The electrically conductive slip ring forms in particular a slip ring arrangement.

[0042] If one conductive slip ring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com