Indirect torque control method for cage-rotor brushless doubly-fed machine (BDFM)

A doubly-fed motor, torque control technology, applied in torque ripple control, estimation/correction of motor parameters, etc., can solve problems such as large torque ripple and large winding current harmonics, and achieves less motor parameters and more efficient solutions. The effect of large harmonic current of control winding and simple system control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is described in further detail below:

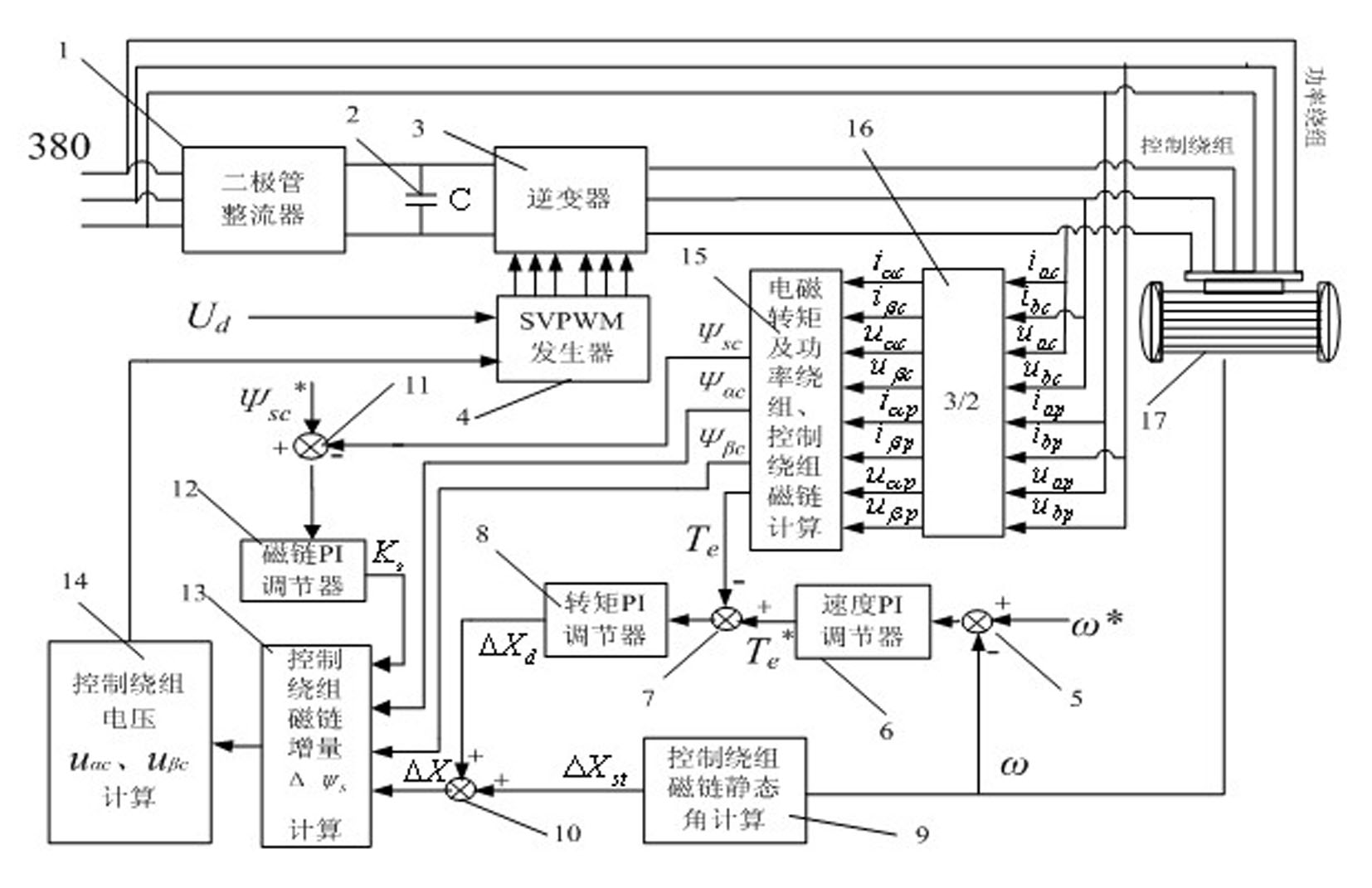

[0018] Such as figure 1 , to realize a method for indirect torque control of cage-type rotor brushless doubly-fed motors according to the present invention is based on the device of brushless doubly-fed motor indirect torque control system, the device is composed of diode rectifier 1, filter capacitor 2. Inverter 3, SVPWM generator 4, comparator 5, speed PI regulator 6, comparator 7, torque PI regulator 8, control winding flux linkage static angle calculation 9, adder 10, comparator 11, Flux linkage PI regulator 12, controlling winding flux linkage increment Calculation 13, Control Winding Voltage , Calculation 14, electromagnetic torque and power winding, control winding flux calculation 15, 3 / 2 converter 16, brushless double-fed motor 17 constitute; six output terminals of SVPWM generator 4 are connected to the control terminal of inverter 3, Output of speed PI regulator 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com