Filtering cloth woven from monofilaments and multifilaments

A single multifilament machine and filter cloth technology, applied in filtration and separation, fabric, textile and other directions, can solve the problems of high cost, easy breeding of bacteria, difficulty, etc., and achieve the effect of prolonging the service life, good filtering effect and good interception effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

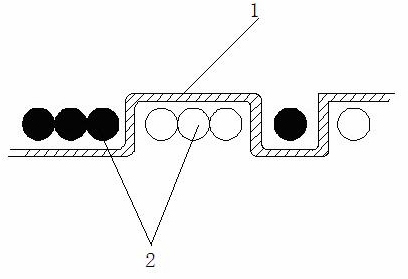

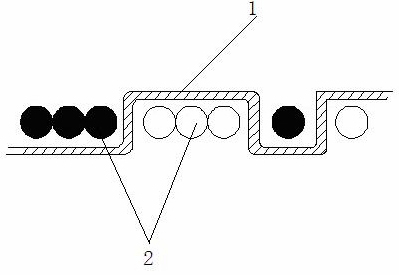

[0009] For an in-depth understanding of a monofilament woven filter cloth, combined with figure 1 , figure 2 described as follows:

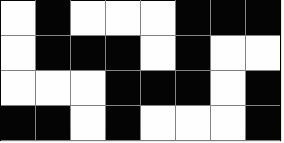

[0010] Single multifilament woven filter cloth, which is woven by warp 1 and weft 2, is characterized in that: warp 1 is made of multifilament, weft 2 is monofilament, and warp 1 and weft 2 are woven into a 3 / 1 1 / 3 composite organizational structure. The warp 1 is composed of polypropylene multifilament, and the specification of the multifilament is 1400D. The weft thread 2 is composed of polypropylene monofilament, and the specification of the monofilament is 0.3 mm in diameter. The multifilaments are concentrated on the upper surface of the filter cloth, and the monofilaments are concentrated on the lower surface of the filter cloth, forming a trumpet-shaped hole with a smooth surface, a small top and a large bottom.

[0011] The filter cloth is interwoven with monofilament and multifilament, and the multifilament completely floats on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com