Optical lens for light-emitting diodes (LEDs)

An optical lens and LED chip technology, applied in the field of lenses, can solve the problems of uneven LED light, limited illumination area, and reduced brightness, and achieve the effects of improving LED luminous efficiency, increasing illumination area, and improving brightness and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

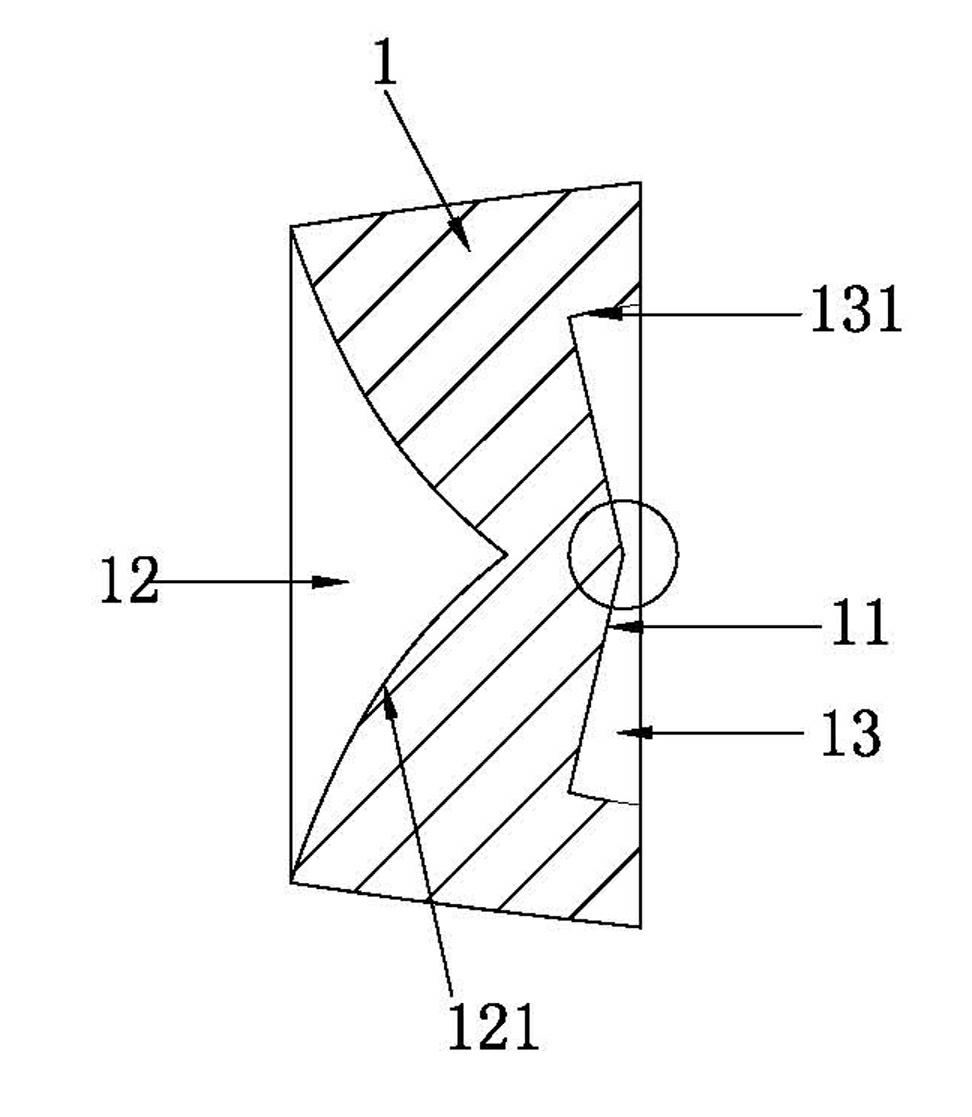

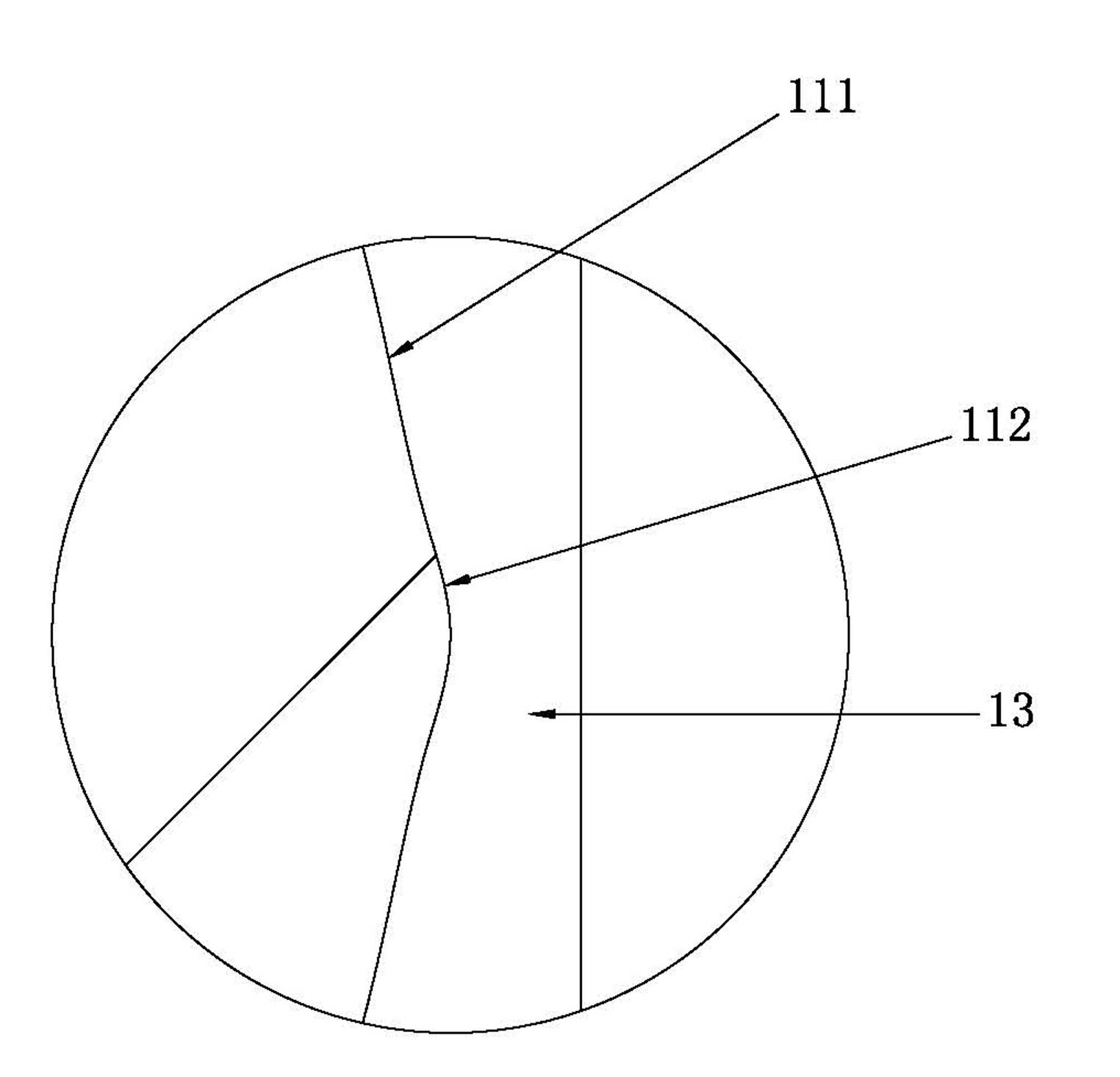

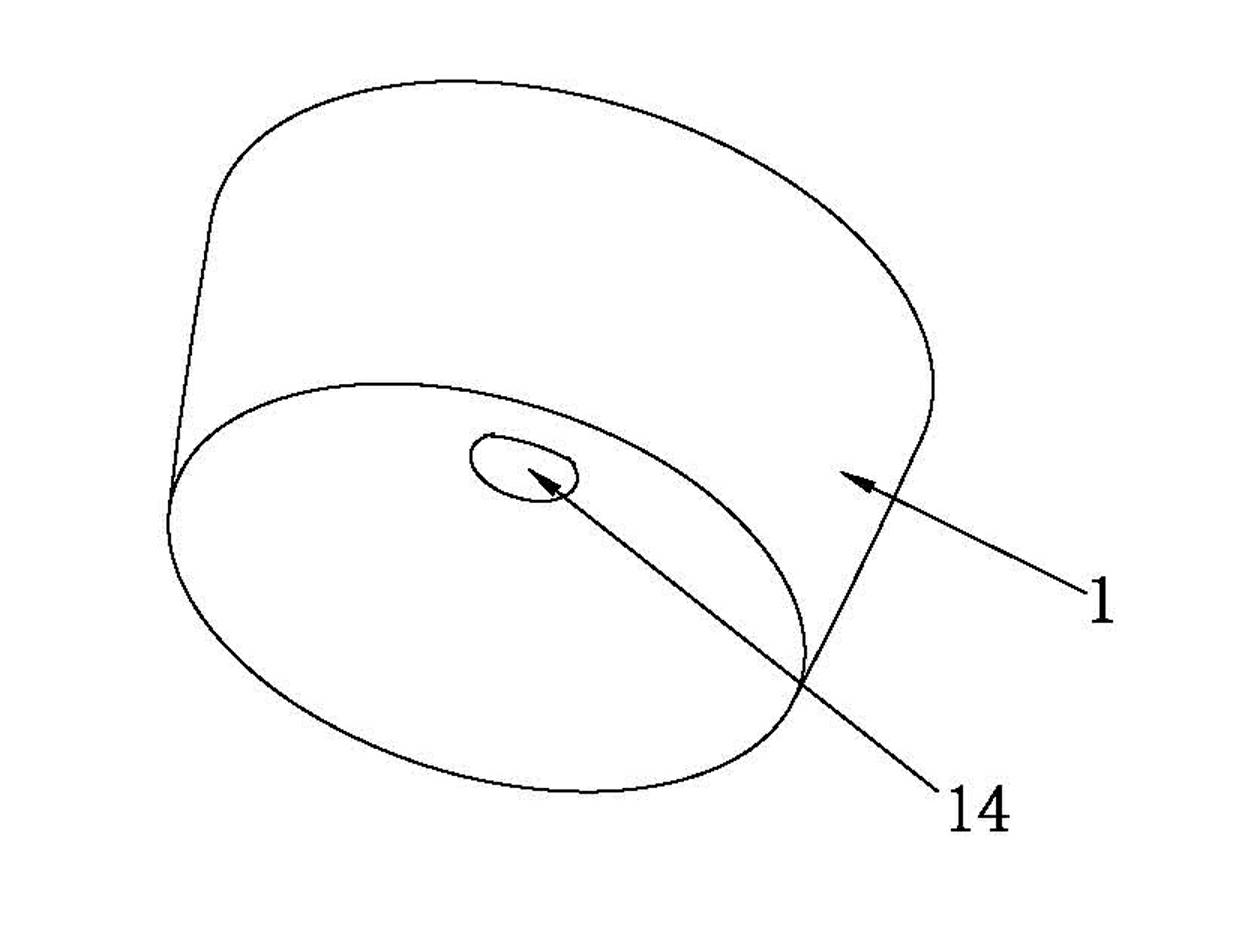

[0017] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of the first embodiment of the present invention. The optical lens for LED shown in the figure includes a cylindrical lens body 1. The cylindrical lens body 1 can be in the shape of a cone or a cylinder. The cylindrical lens The height of body 1 can be determined according to actual needs, certainly, cylindrical lens body also can be other polygonal cylinder shapes, and this lens body 1 has a convex incidence surface 11 and an inner space 12, and this inner space 12 has the structure that makes The light that enters from this incident surface reflects the internal reflection surface 121 of this lens body, and this internal space 12 can be conical shape, also can be other shapes, as can adopt the shape that generatrix is incurved arc, polygonal pyramid etc. .

[0018] Such as figure 2 As shown, the convex incident surface 11 can be a closed curved surface formed by a straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com