Segmented heating type thermocouple liquid level sensor

A liquid level sensor and segmental heating technology, which is applied in the direction of liquid level indicators for physical variable measurement, can solve the problems of liquid droplets interfering with accurate liquid level measurement, affecting the response speed of surrounding media, and false liquid level signals, etc., to achieve shortening Measuring the effect of response time, small inertia, and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

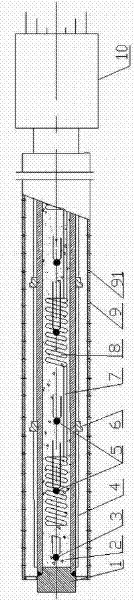

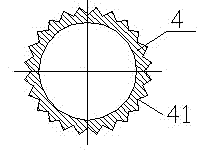

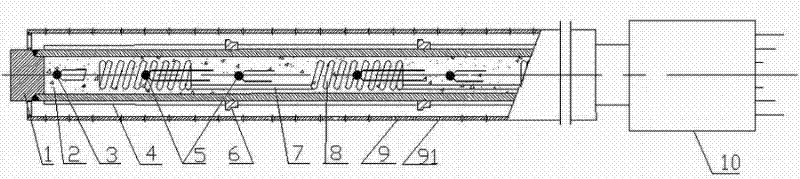

[0016] like figure 1 , 2 As shown, a segmented hot-end heating thermocouple liquid level sensor used in high-reliability occasions consists of hot-end plug 1, insulating material 2, bottom temperature-measuring thermocouple 3, and armored casing with triangular grooves on the surface 4. N pairs of differential thermocouples 5, liquid film blocking cover 6, N segment conductor 7, N segment heating wire 8, porous splash guard 9, and cold end sealing tube 10.

[0017] There are 4 sections of connecting conductor 7 and heating wire 8, 4 pairs of differential thermocouples 5, and the distance between the two nodes is 25mm. ; The insulating material 2 is high-purity MgO.

[0018] Bottom temperature measuring thermocouple 3, 4 pairs of differential thermocouple 5, 4 sections of conductor 7, 4 sections of heating wire 8, insulating material 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com