AFM (Atomic Force Microscope)-based device for performing nanoindentation measurement on surface of microparticle

An atomic force microscope and nanoindentation technology, which is used in measurement devices, scanning probe microscopy, instruments, etc., can solve the problem that the sample position is not easy to fix, the particle size is small, and the needle process and indentation position of the nanoindentation needle are affected. choice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

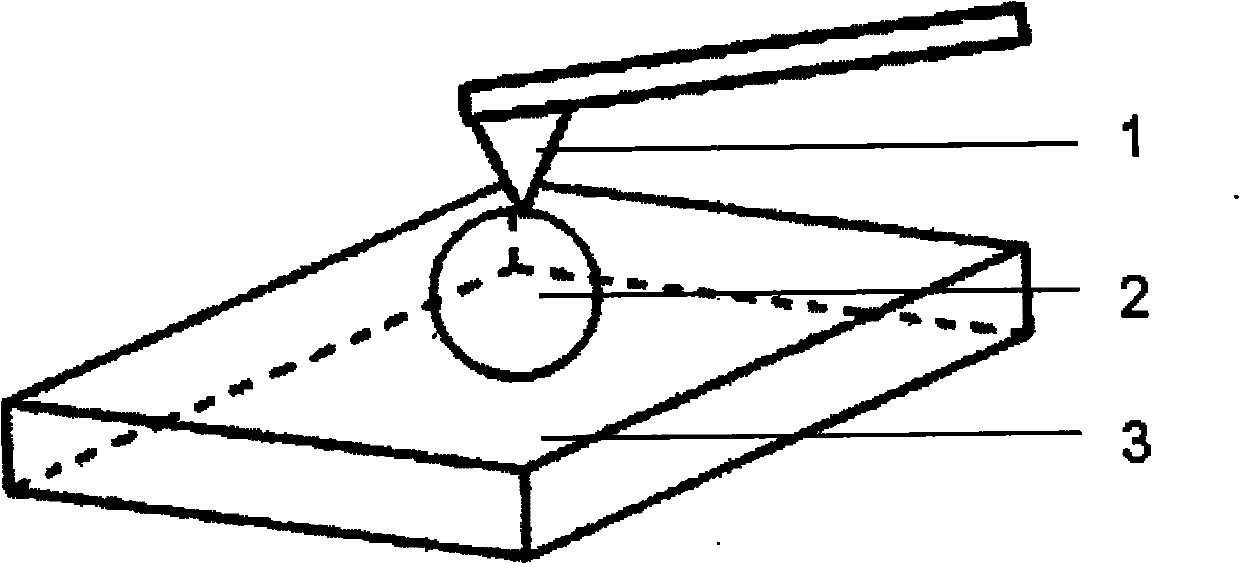

[0025] Embodiment 1: a kind of measurement device based on the nano-indentation of the surface of microparticles of atomic force microscope (see figure 1 ), which is composed of an atomic force microscope system, including a scanning controller, a scanning probe microscope main body, a magnifying glass display system, a computer host, a monitor, a keyboard and a mouse, wherein the scanning probe microscope main body includes a base, a scanning tube, a needle tip holder, Electronic circuit connection unit, laser optical path and magnifying glass system, characterized in that there is a sheet plane (3) on which the sample to be tested (2) is placed on the sample stage on the top of the scanning tube, and the sheet plane (3) is bonded and fixed to be tested. The double-sided adhesive tape of the sample (2) is fixed in the tip holder, and the nano-indentation tip (1) for scanning and nano-indentation operations is arranged, and the nano-indentation tip (1) is placed above the sampl...

Embodiment 2

[0040] Embodiment 2: a kind of measurement device based on the nano-indentation of the surface of microparticles of atomic force microscope (see figure 1 ), which is composed of an atomic force microscope system, including a scanning controller, a scanning probe microscope main body, a magnifying glass display system, a computer host, a monitor, a keyboard and a mouse, wherein the scanning probe microscope main body includes a base, a scanning tube, a needle tip holder, Electronic circuit connection unit, laser optical path and magnifying glass system, characterized in that there is a sheet plane (3) on which the sample to be tested (2) is placed on the sample stage on the top of the scanning tube, and the sheet plane (3) is bonded and fixed to be tested. The double-sided adhesive tape of the sample (2) is fixed in the tip holder, and the nano-indentation tip (1) for scanning and nano-indentation operations is arranged, and the nano-indentation tip (1) is placed above the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com