Heat sink assembly and electronic device applying the same

A technology of a heat sink and a joint, which is applied to circuits, electrical components, electrical solid devices, etc., can solve problems such as short circuits, burning electronic components, and increasing production costs, reducing material costs and assembly costs, and assembling simple and firm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

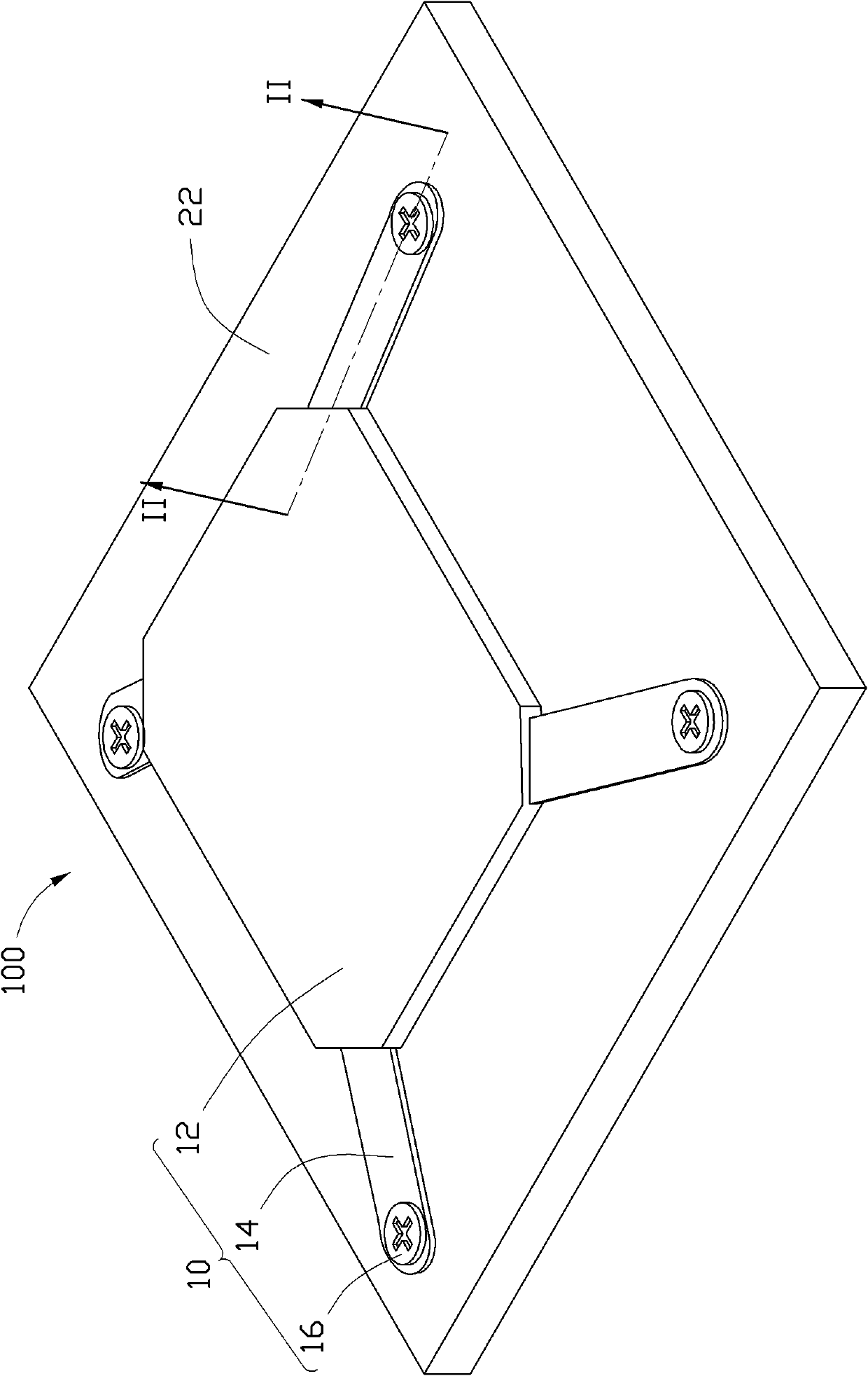

[0030] see figure 1 and figure 2 , which is an assembly diagram of an electronic device 100 of the present invention. The electronic device 100 includes a heat sink assembly 10 and an electronic component 20 . The heat sink assembly 10 attaches the electronic component 20 to dissipate heat from the electronic component 20 .

[0031] The heat sink assembly 10 includes a square substrate 12, four extension arms 14 extending horizontally from the four corners of the substrate 12, and four turnbuckles that cooperate with the extension arms 14 to fix the substrate 12 on the electronic component 20. Tool 16.

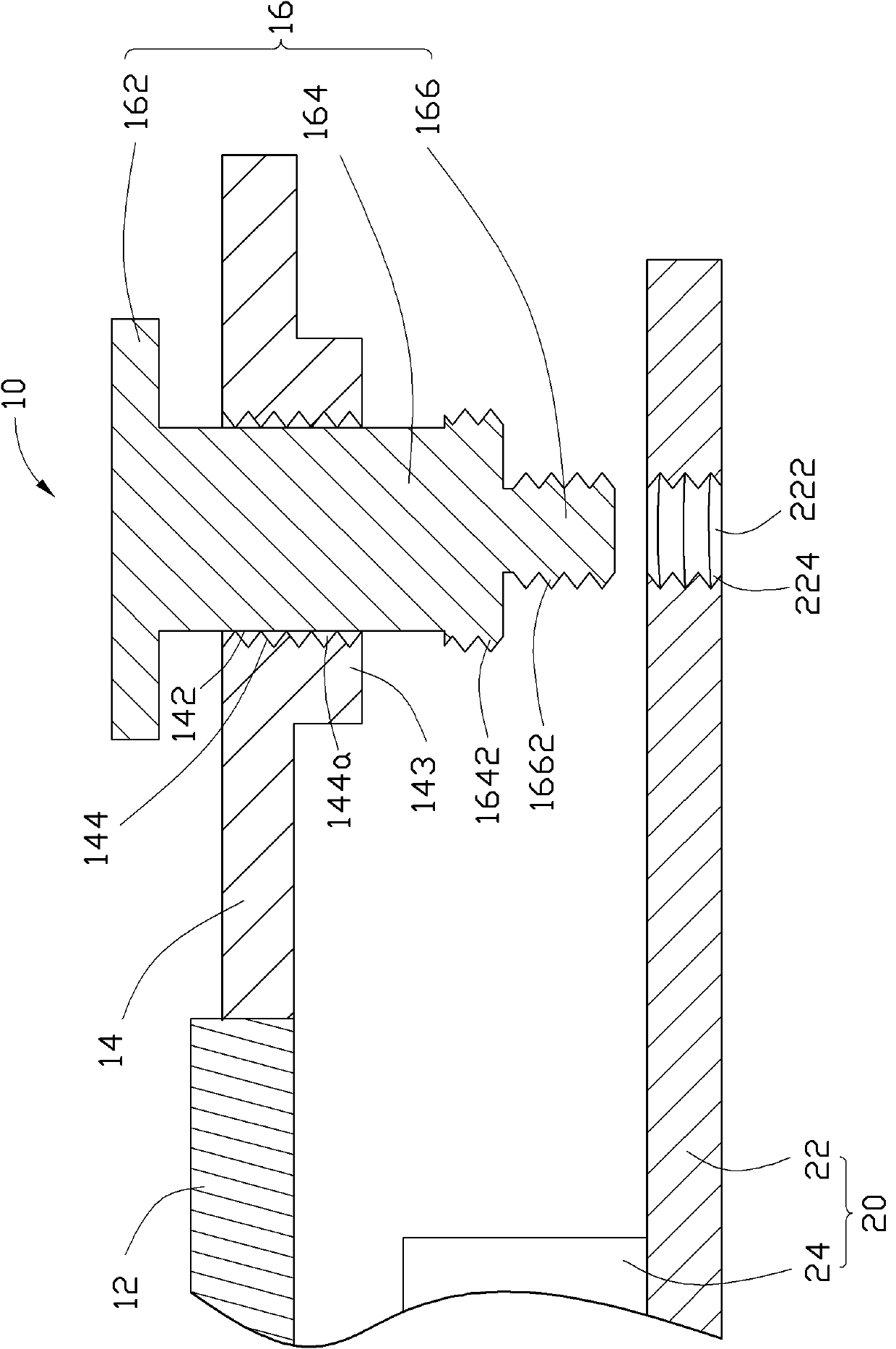

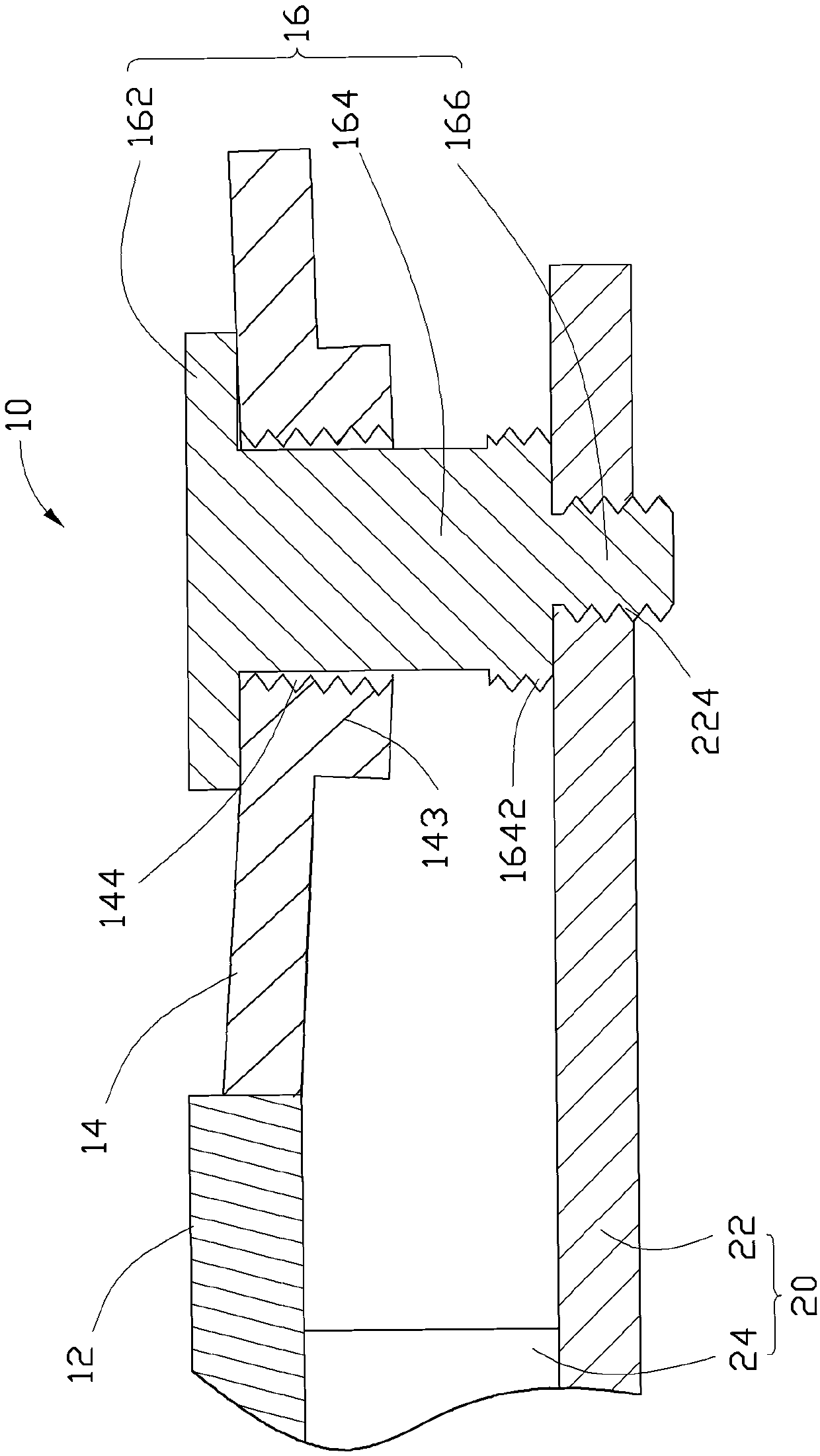

[0032] The substrate 12 is made of a material with good thermal conductivity, such as aluminum, copper, etc., and is used for contacting with the electronic component 20 to absorb its heat. Each of the extension arms 14 is a longitudinal elastic sheet thinner than the base plate 12. The end of each extension arm 14 is provided with a first through hole 142, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com