Belt press filter for superfine and strong viscous materials

A filter and viscous technology, applied in filtration and separation, moving filter element filter, dewatering/drying/concentrating sludge treatment, etc., can solve the problem of unsuitability of ultra-fine and viscous materials, and increase the loosening of sludge. high stability, increased shear force, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

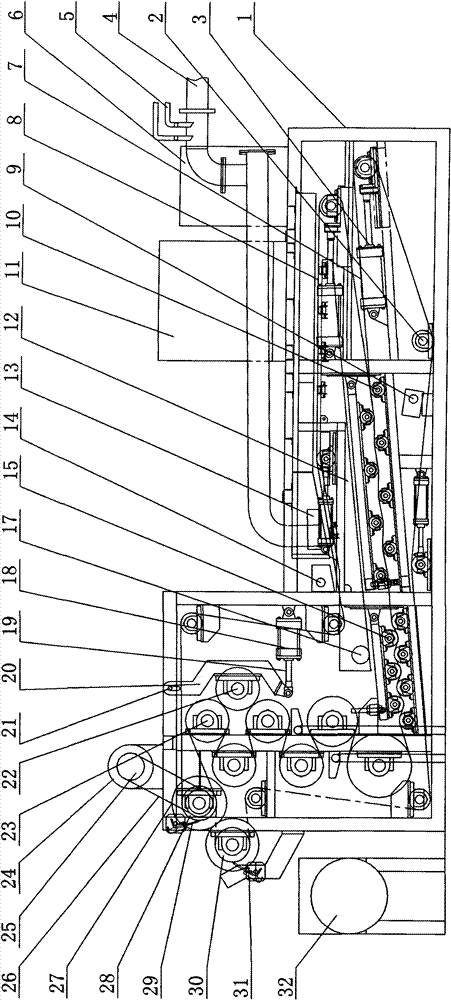

[0011] The present invention includes a frame 1, an electric control box 11 and a pneumatic control box 6 are arranged on the frame 1, the upper part of the frame 1 is a sludge conveying pipe 4 with a medicine inlet 5, and the side of the frame 1 is provided with an upper and lower A pair of meshing identical gears 27, the gears 27 are driven by the chain 26 on the sprocket 25 on the motor 24, the shafts of the pair of gears 27 are respectively provided with an upper press roll 28 and a lower press roll 30; The upper filter belt 8 passes through the output port 13 of the sludge conveying pipe 4 in the frame 1 in turn, and bypasses a total of 12 to 20 small-diameter pre-pressing rolls 10, small-diameter pressing rolls 15, and strong pressing rolls 23. Return to the upper press roll 28; the lower filter belt 7 on the lower press roll 30 bypasses the intermediate roll 2, overlaps the upper filter belt 8 on the small-diameter pre-press roll 10, and then passes through the small-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com