Beneficiation process of low-grade magnetite and specularite mixed ore

A technology of magnetite and specularite, which is applied in the field of ferrous metal ore mining and dressing, can solve the problems of unsuitable mixed ore dressing process, complicated process flow, and high dressing cost, so as to improve the dressing efficiency, reduce energy consumption, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

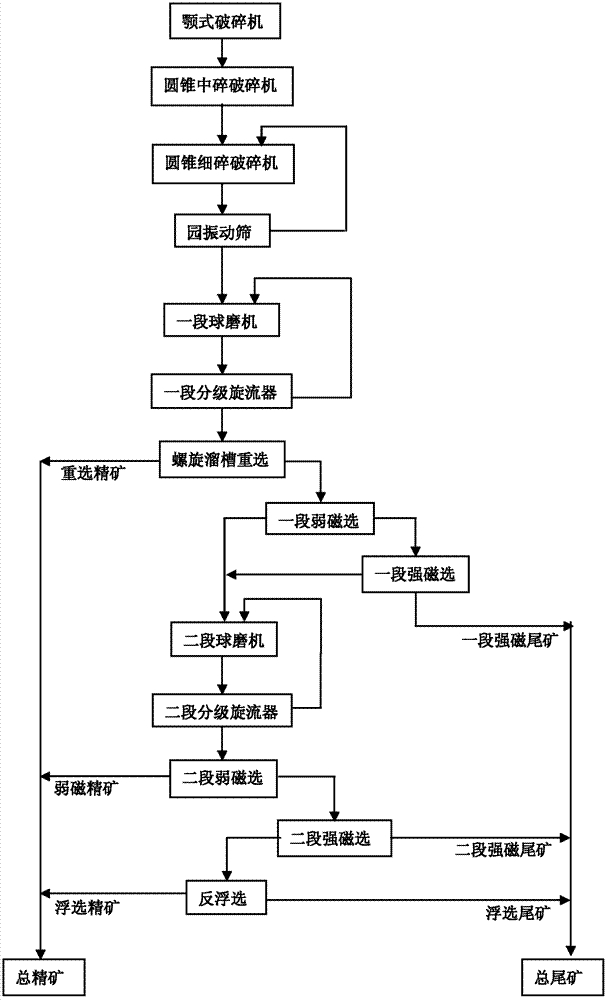

Image

Examples

Embodiment Construction

[0027] The beneficiation process of the present invention is used to beneficiate the Huoqiu Zhouyoufang iron ore in Anhui, and the specific process is as follows:

[0028] Ore crushing process: adopting three-stage one-closed-circuit crushing process. The ore is respectively crushed by Metso C140 jaw crusher and two Metso HP500 cone crushers for coarse crushing, medium crushing and fine crushing, and then through circular vibrating screen. The crushed ore product under the sieve has a particle size of less than 12mm as a qualified particle size, and enters the next process. The coarse particles on the sieve are returned to the crusher to be crushed;

[0029] One-stage grinding and grading process: the above-mentioned crushed ore products enter the first-stage grinding and grading operation, which is composed of an overflow type ball mill and a cyclone to form a closed-circuit grinding cycle. The first stage grading overflow has a particle size of 200 mesh, accounting for about 50-55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com