Cold extrusion die for double end pipe joint

A cold extrusion, double-ended tube technology, applied in metal extrusion dies and other directions, can solve problems such as time-consuming and labor-intensive, inability to complete product demoulding, and failure to meet precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

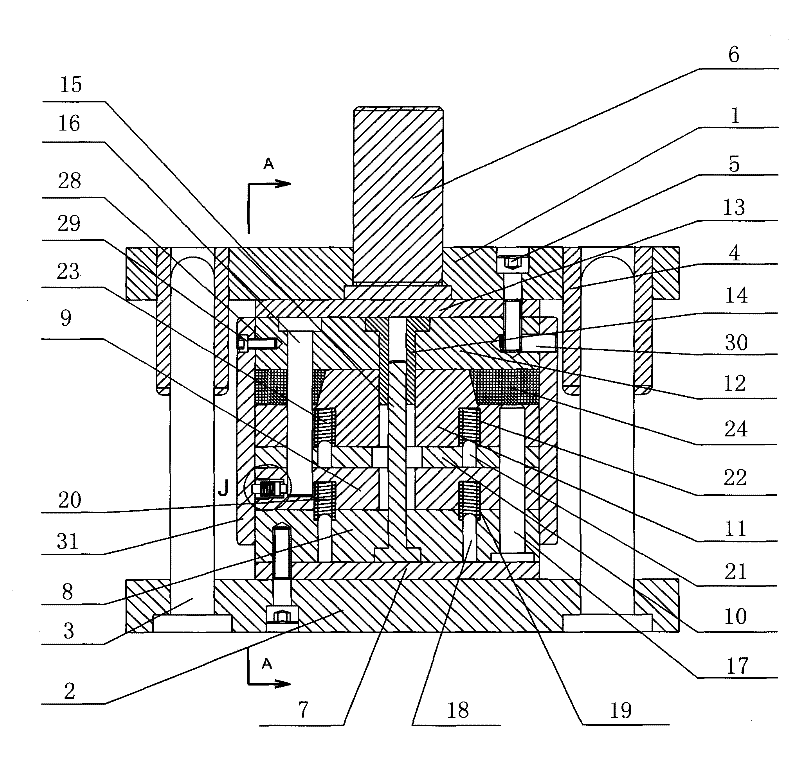

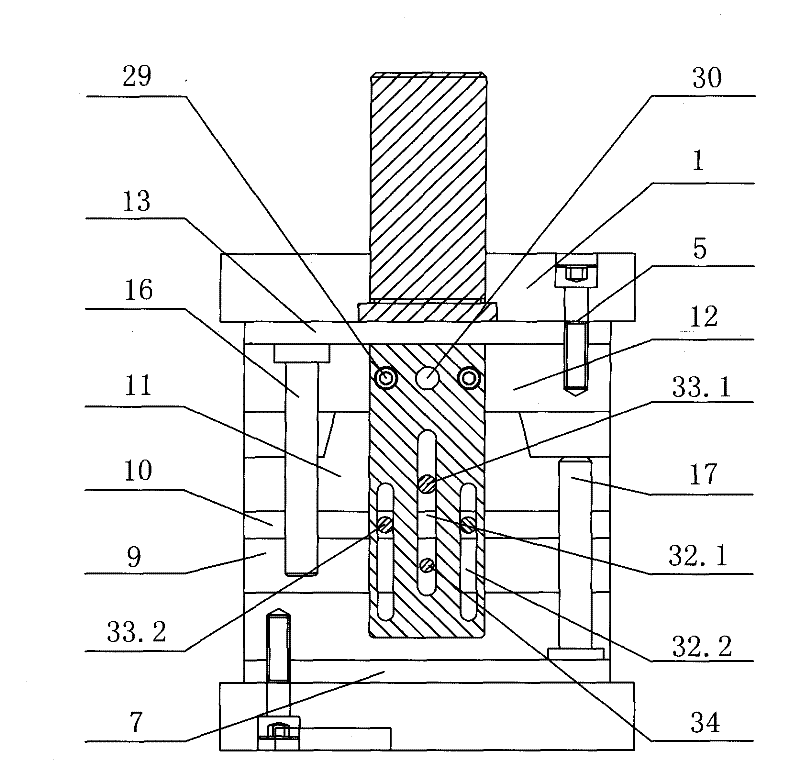

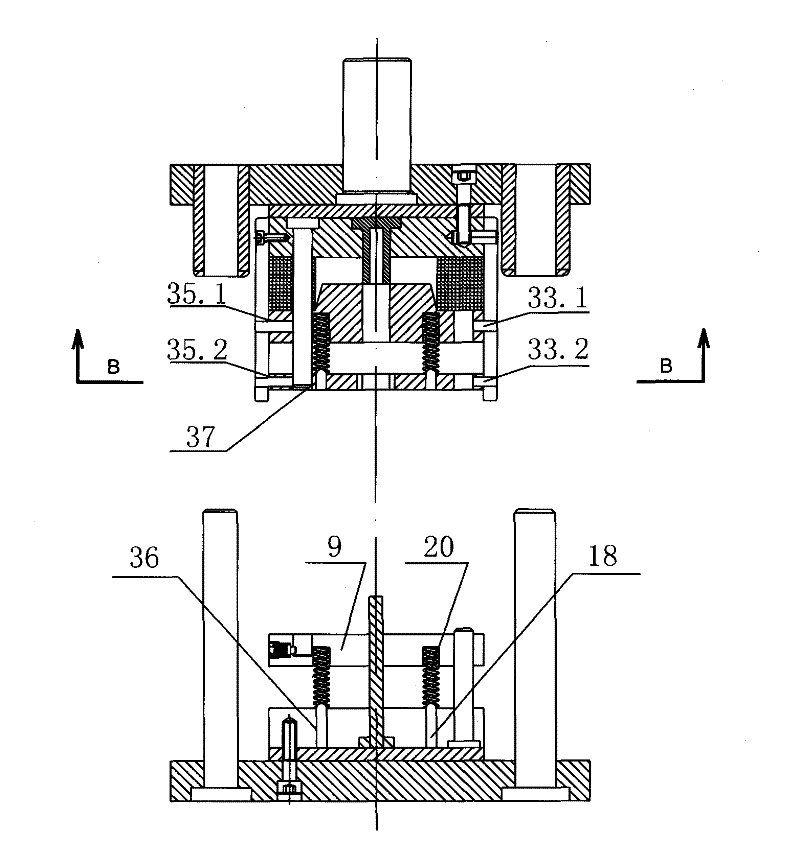

[0022]The cold extrusion die for the twelve-corner double-head pipe joint includes an upper template 1, a lower template 2, two guide posts 3, two guide sleeves 4, four hexagon socket bolts 5, and a die handle 6. The mold frame, the mold handle 6 is embedded in the center position of the upper template 1, and the lower end of the mold handle 6 is supported on the upper mold backing plate 13. It also includes the upper end of the following template 2 as the base surface, and there are a lower mold backing plate 7, a lower mold fixing plate 8, a lower mold sleeve 9, a middle mold sleeve 10, and an upper mold sleeve 11 from bottom to top. , a patrix fixed plate 12, a patrix backing plate 13; Wherein the upper formwork 1, the patrix backing plate 13, the patrix fixed plate 12 are fastened and connected with bolts 5 to form a whole; wherein the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com