Active sleeve-withdrawing device for hose assembling machine

A technology of assembly machine and sleeve withdrawal, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems that the ferrule cannot put the hose in, does not meet the expected requirements, and the top of the ferrule is aggressive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further elaborate the present invention below in conjunction with embodiment and accompanying drawing:

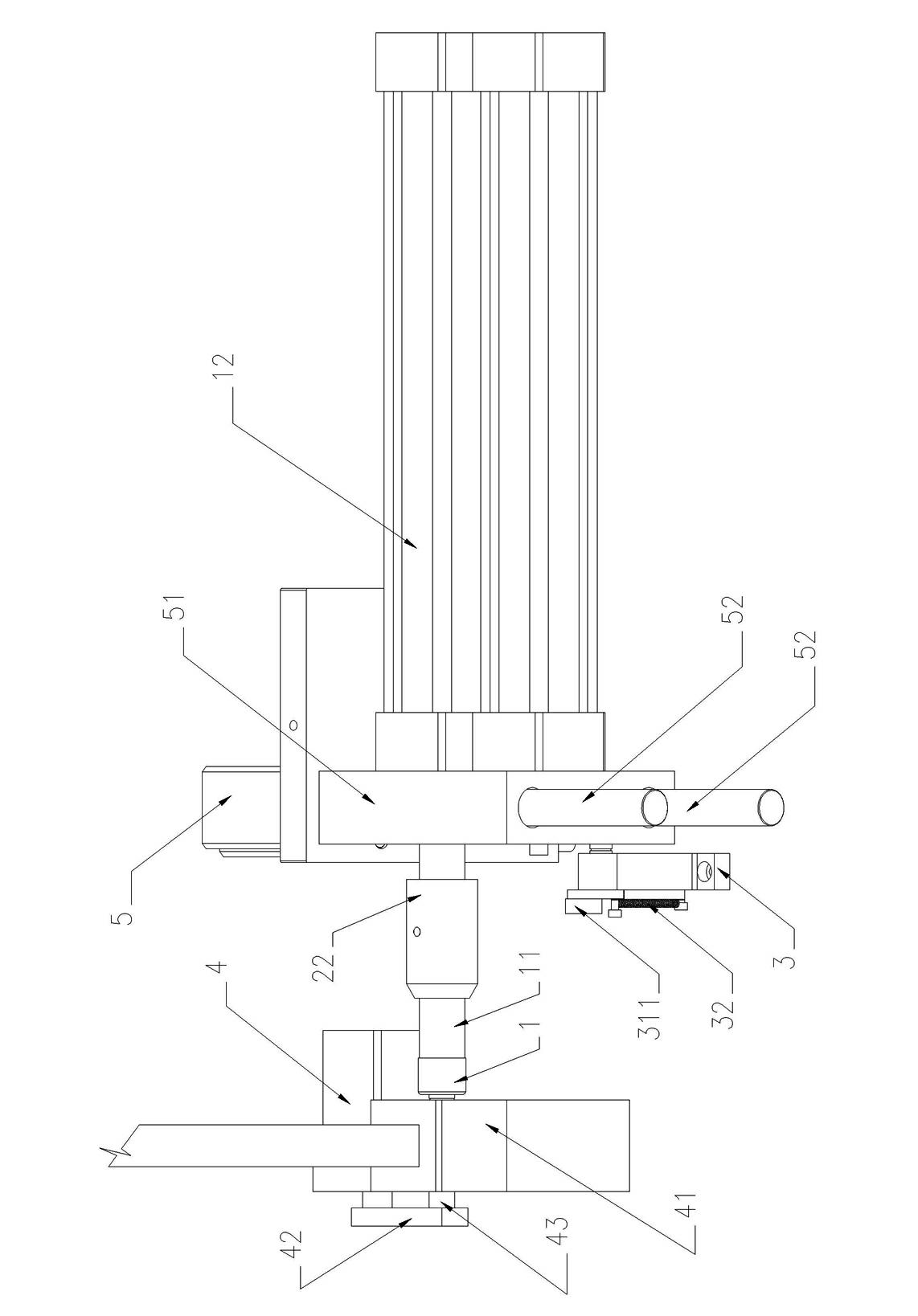

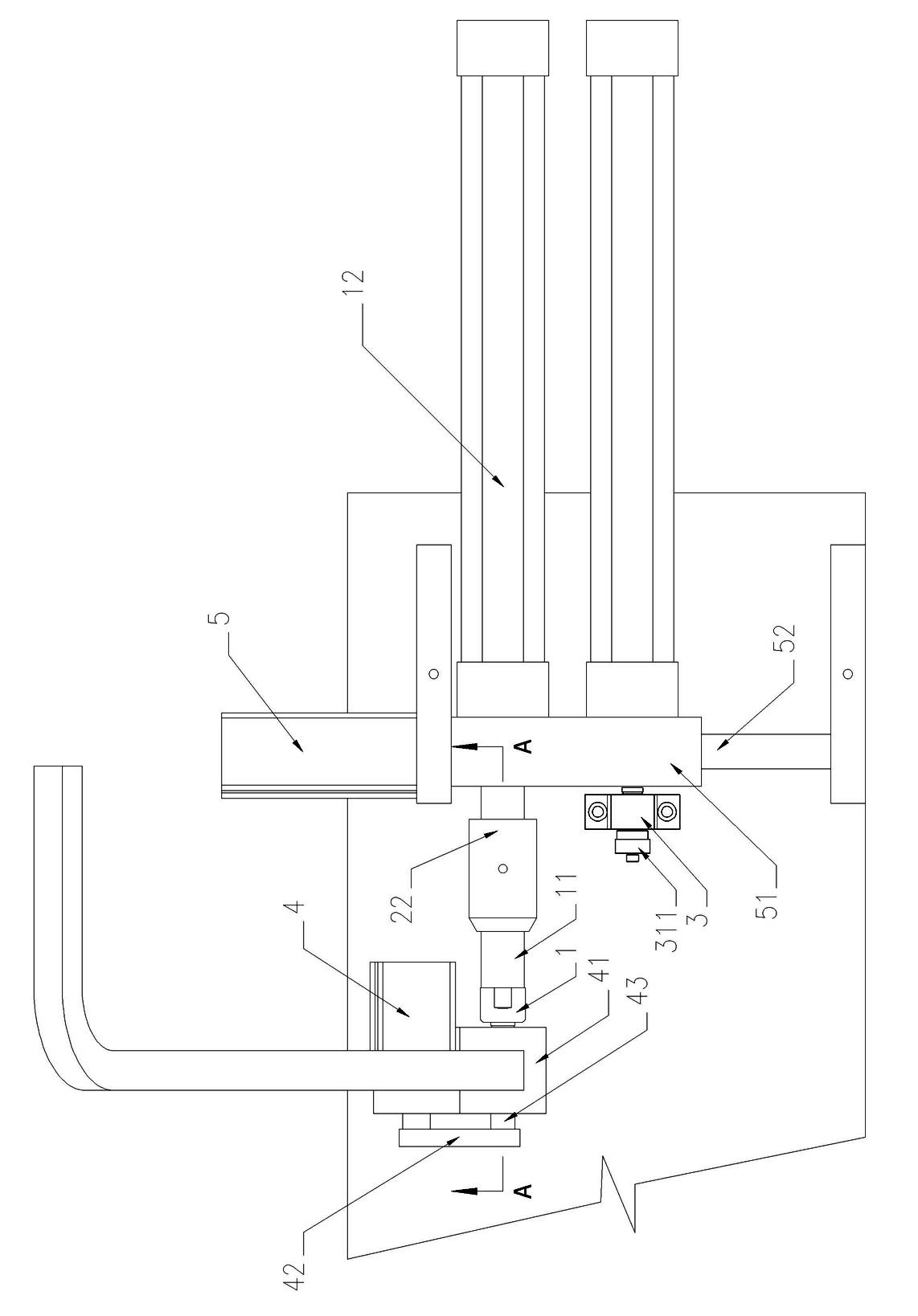

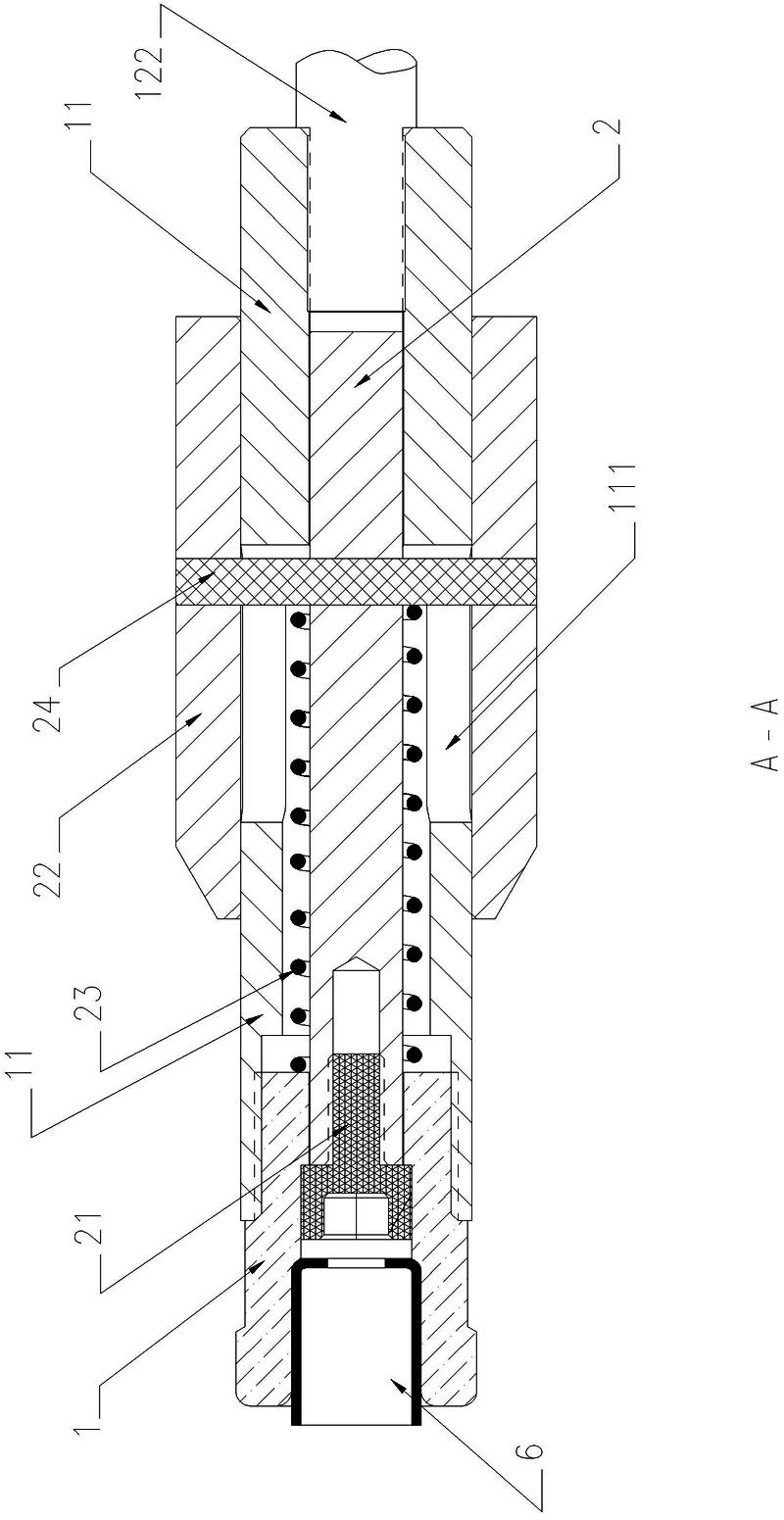

[0030] Such as Figure 1 to Figure 6 The active retracting device of the hose assembly machine shown in the figure is controlled by the microcomputer control system to control the movement direction and movement time of each cylinder, so as to realize the automatic operation of each mechanical part; The sheet 42 and mandrel 43 move to the left, and the ferrule 6 in the cover base 41 falls into the top cover position, as figure 1 figure 2 As shown, at the same time, the lateral movement cylinder 5 pulls the displacement cylinder seat 51, so that the sleeve head 1 is aligned with the sleeve removal position of the sleeve base 41, and the cylinder ejector rod 122 of the cylinder 12 ejects the sleeve head 1 and stops at the sleeve removal position. The "door" is waiting.

[0031] Then the ejector rod of getting cover cylinder 4 under microcomputer control drives conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com