Stonepaper honeycomb cardboard and manufacturing method thereof

A technology of honeycomb cardboard and stone paper, which is applied to cardboard items, etc., can solve the problems of application limitations of honeycomb cardboard, and achieve the effect of smooth surface, good physical strength and good moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

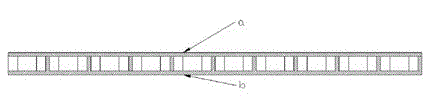

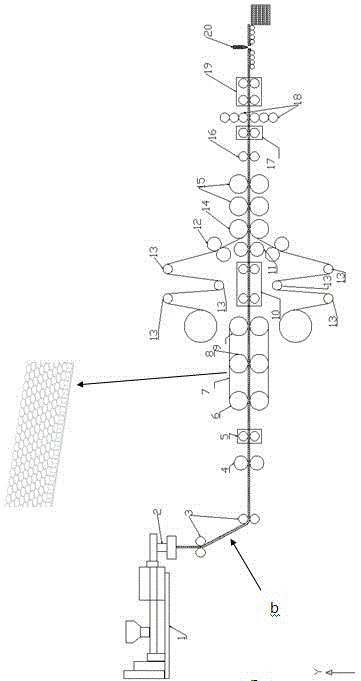

[0035] Example 1 Manufacture of single-layer stone paper micro-honeycomb paperboard (refer to image 3 )

[0036] a. Raw material granulation process Single-layer micro-stone paper honeycomb paperboard uses 75 parts of natural inorganic mineral powder (mainly composed of calcium carbonate, including calcium sulfate, barium sulfate, mica powder, zinc oxide, dolomite powder, talcum powder, silicon dioxide, etc.) as the main raw material , with 20 parts of HDPE (high density polyethylene), 2.3 parts of modifiers (including 0.8 parts of aluminate, 1 part of JL-G modifier, 0.5 parts of stearic acid), 2.1 parts of processing aids (including 0.6 1 part of polyvinyl ester CH-4, 1.5 parts of solid paraffin 56#), 2 parts of functional additives (calcium carbonate modified whitening agent). First, the main raw material, natural inorganic mineral powder, is mixed and dried; then the dried inorganic materials and modifiers are added to the mixing / modification equipment and mixed to ...

Embodiment 2

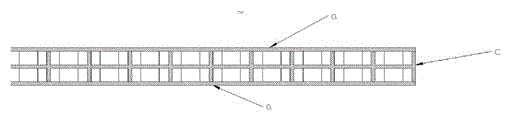

[0041] Example 2 Manufacture of double-layer stone paper honeycomb paperboard (reference Figure 4 )

[0042] a. Raw material granulation processDouble-layer stone paper honeycomb paperboard uses 75 parts of natural inorganic mineral powder (mainly composed of calcium carbonate, including calcium sulfate, barium sulfate, mica powder, zinc oxide, dolomite powder, talcum powder, silicon dioxide, etc.) as the main raw material. With 20 parts of HDPE, 2.3 parts of modifiers (including 0.8 parts of aluminate, 1 part of JL-G modifier, 0.5 parts of stearic acid), 2.1 parts of processing aids (including 0.6 parts of polyvinyl ester CH-4 , 1.5 parts of solid paraffin wax 56#), 2 parts of functional additives (calcium carbonate modified whitening agent). Then activate the modified inorganic materials and functional additives 、 The processing aid and HDPE are added to the mixing equipment and mixed evenly, put into the granulation equipment 1, and banburyed in the granulation equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com