Sectioned lead screw type lifting device

A technology of lifting device and lead screw, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of insufficient safety of jacking structure, large horizontal component force, geometric deformation, etc., and is suitable for large batches The effect of manufacturing, good safety, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

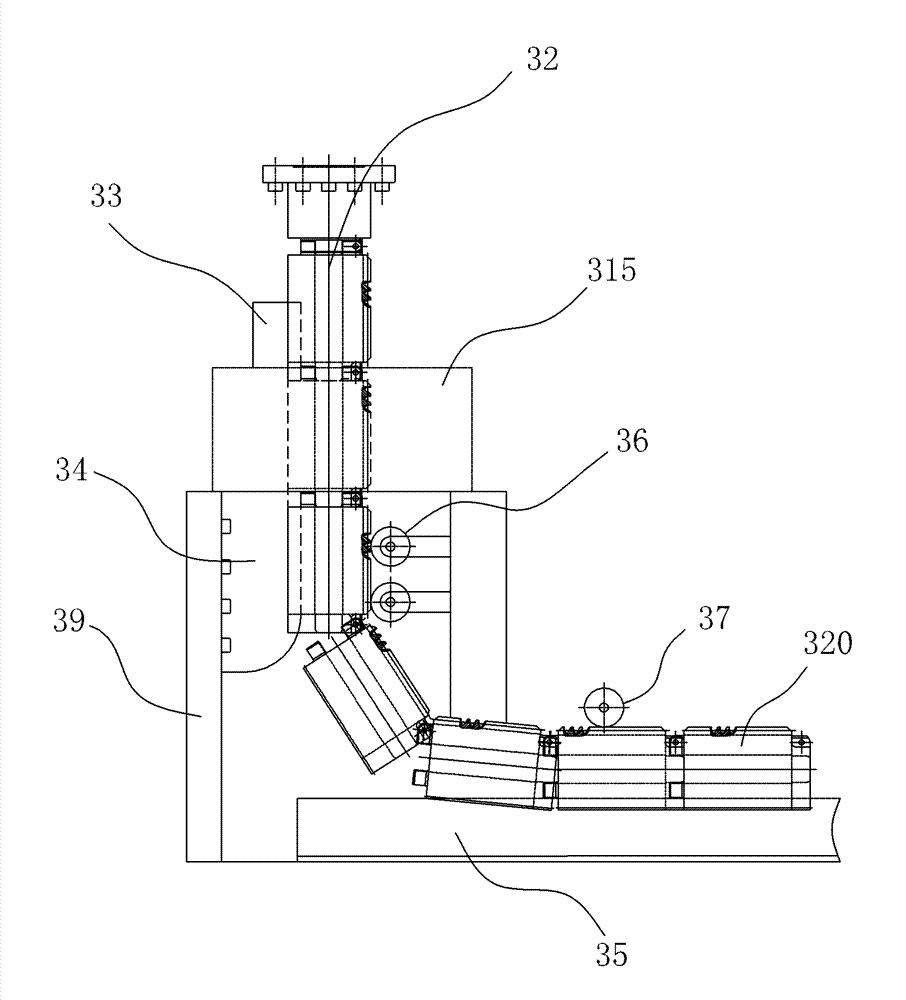

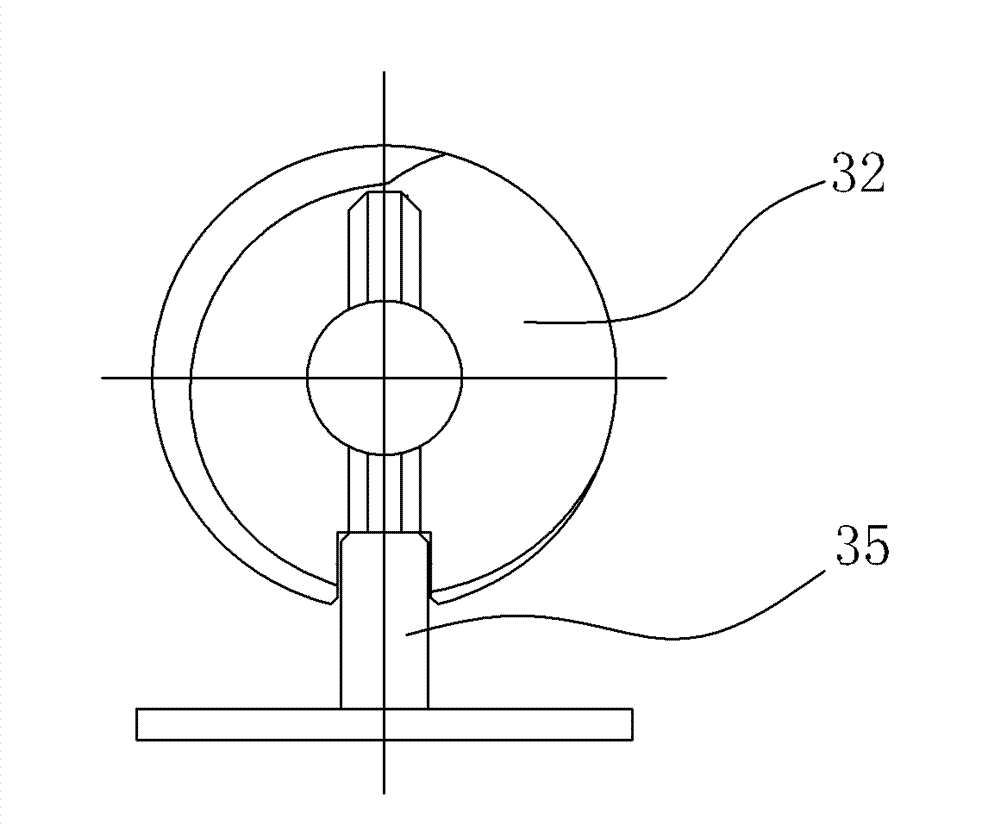

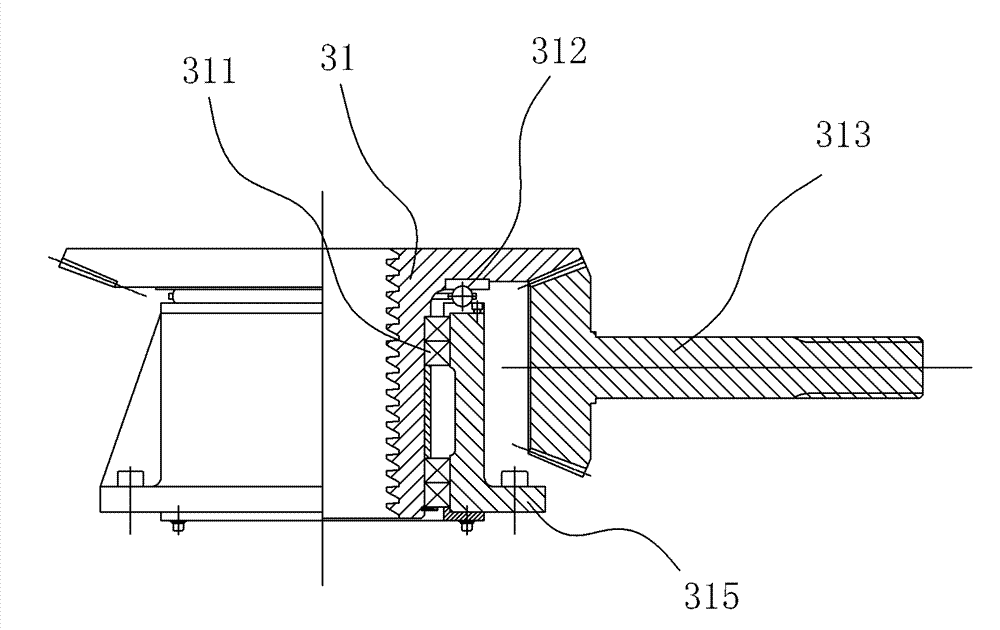

[0031] Embodiment: a segmented screw type lifting device of the present invention, as attached figure 1 , attached image 3 , attached Figure 10 , attached Figure 11 , attached Figure 12 As shown, it includes a lead screw 32 that can be connected to the bottom of the lifting platform 4, and a rotating nut 31 that can be rotated under the actuation of an external drive device. In the structure bent to one side, the vertical section between the rotating nut 31 and the lifting platform 4 is rigid, and the rest is flexible; the two ends of the segmented screw 320 are parallel to each other. The engaging thread of the segmented lead screw 320 and the rotating nut 31 is a zigzag thread. The larger end of the rotary nut 31 thread angle is set downward.

[0032] as attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 As shown, the two end surfaces 321 and 322 of the segmented lead screw 320 are planes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com