High performance direct shearing apparatus for large contact surfaces

A contact surface, high-performance technology, applied to instruments, using stable shear force to test the strength of materials, measuring devices, etc., can solve the problem of uneven force on the sample surface, change of shear area, small shear area, etc. problems, to achieve the effect of high degree of equipment automation, large shear surface size and high measurement accuracy

Active Publication Date: 2011-10-05

NANJING HYDRAULIC RES INST

View PDF5 Cites 50 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] But the above-mentioned direct shear instrument more or less cannot meet the following problems: the shear area is small, and it cannot adapt to the requirements of the direct shear test of coarse-grained soil samples; The problem of upturning of the upper shear box during the test; the uneven force on the sample surface during the normal force transmission; the change of the shear area during the direct shear process; the complicated operation of the hydraulic control; The adaptability of the friction characteristic test is not strong; it is difficult to prepare large-scale direct shear test samples; the automation level of the equipment is not enough, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0039] Example 1, NHRI-4000 high-performance large contact surface direct shear instrument.

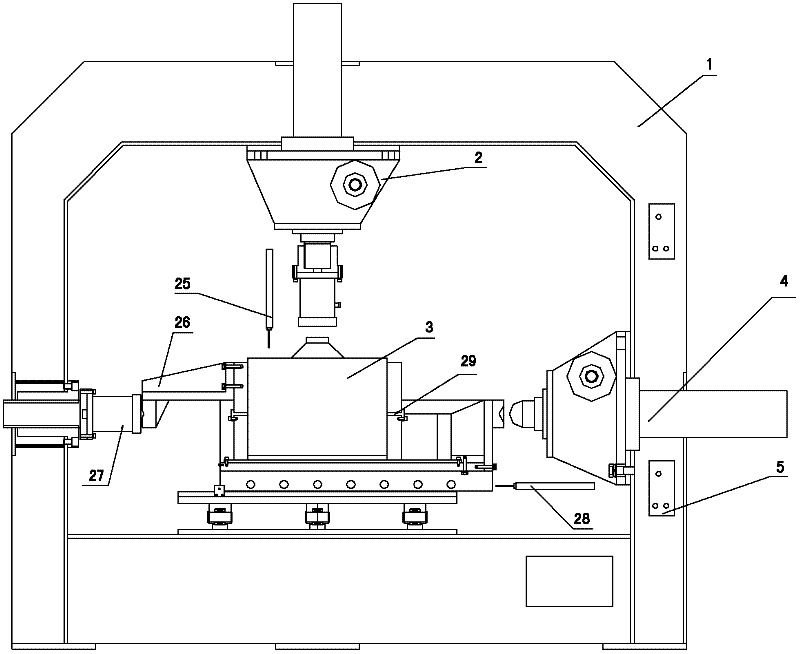

[0040] See figure 1 As shown, it mainly includes a frame assembly 1 , a normal force applying device 2 , a shear box device 3 , a shearing force applying device 4 and an electrical control component 5 .

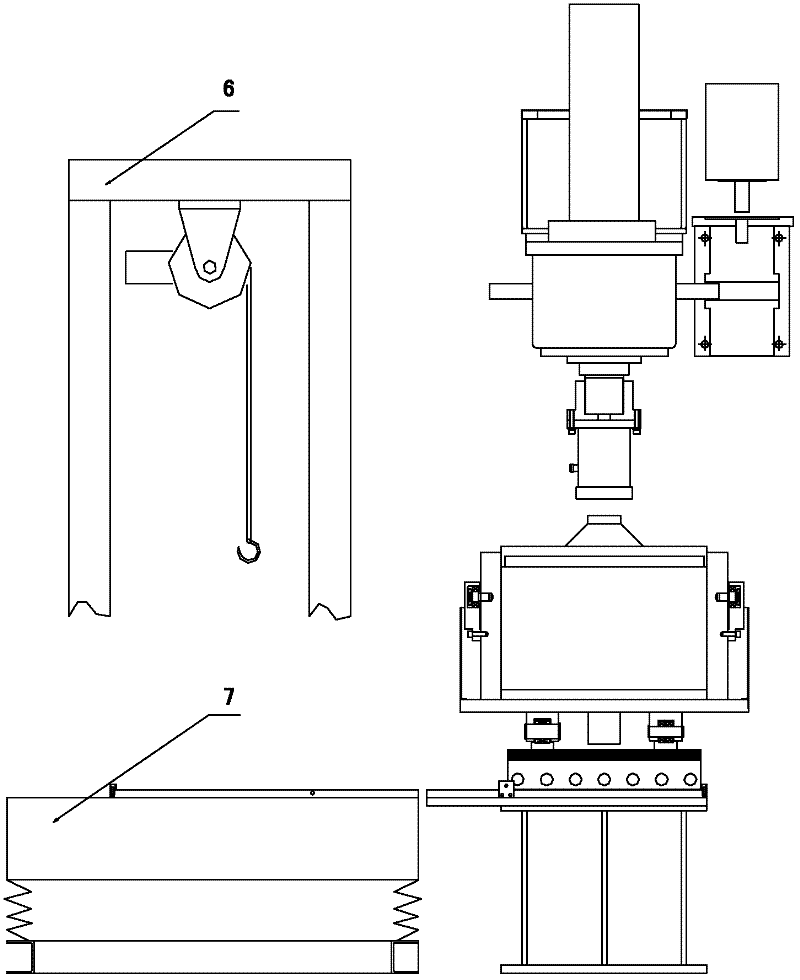

[0041] See figure 2 As shown, it mainly includes a lifting device 6 and a vibrating table 7.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

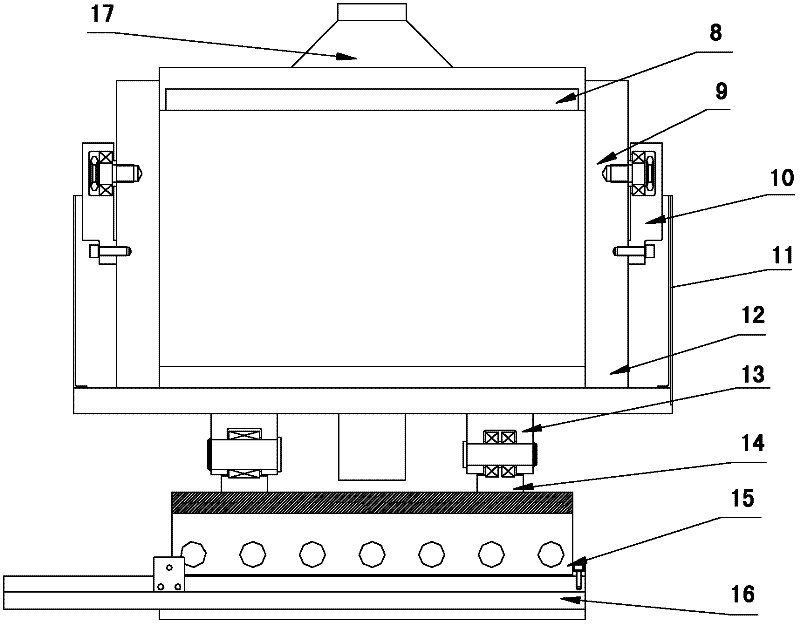

The invention discloses a high performance direct shearing apparatus for large contact surfaces. A large vibration table is arranged on the back side of a frame. A Y-direction guide way and an X-direction rolling guide way are arranged on the vibration table. A shear box apparatus is rolling along the X-direction guide way and the Y-direction guide way. An elevating apparatus is arranged above the vibration table. The shear box apparatus is divided into an upper shear box and a lower shear box. A normal force applying apparatus, a normal force load sensor and a normal deformation displacementsensor are arranged on the upper part of the frame. A shearing force applying apparatus is arranged on the right side of the frame. A shearing force load sensor and a shearing deformation displacement sensor are arranged on the left side of the frame. A computer-controlled data collecting apparatus is also arranged in the apparatus. Data collected by the normal force load sensor, the normal displacement sensor, the shearing force load sensor and the shearing displacement sensor is transmitted to the computer through RS-232 interfaces. The apparatus is characterized in that: a rigid pressure transferring plate and an elastic baffle plate are arranged between a sample in the shear box and the normal force applying apparatus; and the lower shearing box is fixed on a high-strength rigid plate. The apparatus provided by the present invention has advantages of high measuring precision, large shearing surface size, and high automation degree.

Description

technical field [0001] The invention relates to a test device, in particular to a high-performance large-scale contact surface direct shear instrument, which is suitable for measuring the internal friction characteristics of various materials such as concrete materials, earth and rocks, and is especially suitable for the relationship between different materials such as concrete materials and earth and rocks, Research on the mechanical properties and deformation mechanism of the contact surface of braided fabrics. The equipment can be used for constant shear surface direct shear test and variable shear surface direct shear test. Background technique [0002] The contact interface of different materials is often encountered in civil engineering and hydraulic engineering. Due to the difference in the mechanical properties of the materials on both sides of the contact interface, there are often large shear stresses and displacement discontinuities on both sides of the interface...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/24G01N19/02

Inventor 蔡正银茅加峰傅华凌华徐光明胡翔韩华强白鹭王芳曹培

Owner NANJING HYDRAULIC RES INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com