Storage battery charging method

A charging method and battery voltage technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problems of battery service life impact, battery thermal runaway, thermal runaway, etc., to prevent charging thermal runaway, The effect of prolonging the service life and increasing the rate of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

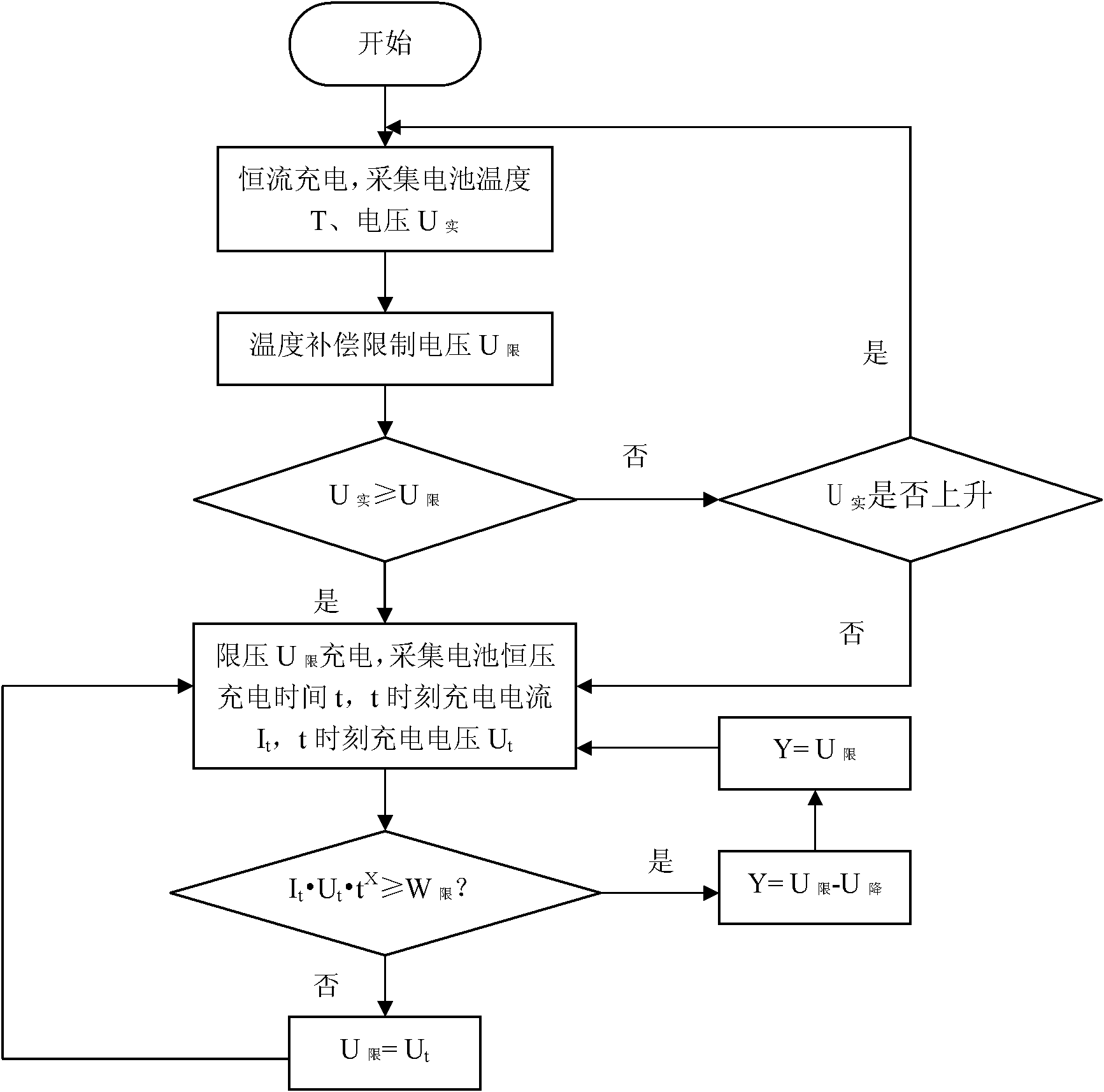

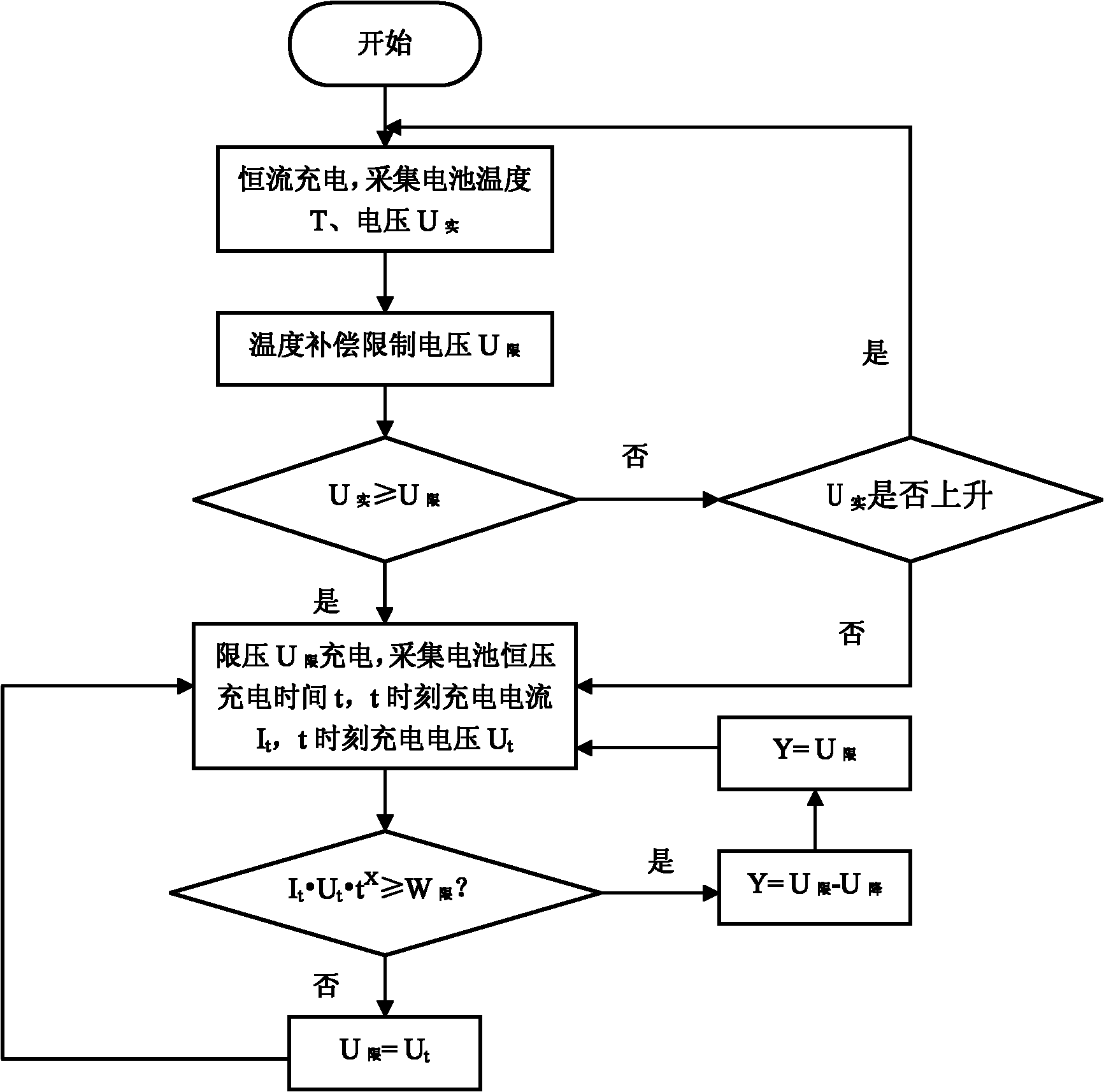

[0020] refer to figure 1 Embodiment 1 of a battery charging method of the present invention, a battery charging method, is carried out in accordance with the following steps:

[0021] A. First measure the temperature T of the battery, according to U 限 =n[U 25℃ +k(T-25)] formula to calculate battery charging limit voltage U 限 value, where U 25℃ It is the battery charging limit voltage at 25°C, the range is 2.35~2.50V / cell; k is the temperature compensation coefficient, the range is -5~-2mV / °C; n is the number of cells connected in series; the battery is charged with constant current, The constant current value is 0.05 to 0.5 times the rated capacity value of the two-hour rate of the battery;

[0022] B. Collect battery voltage U every 600 seconds 实 , compare U 实 and battery charge limit voltage U 限 value, if U 实 ≥U 限 , then the battery enters the limited voltage charging stage and adopts U 限 Charging; if the battery voltage U 实 Battery charging limit voltage U not re...

Embodiment 2

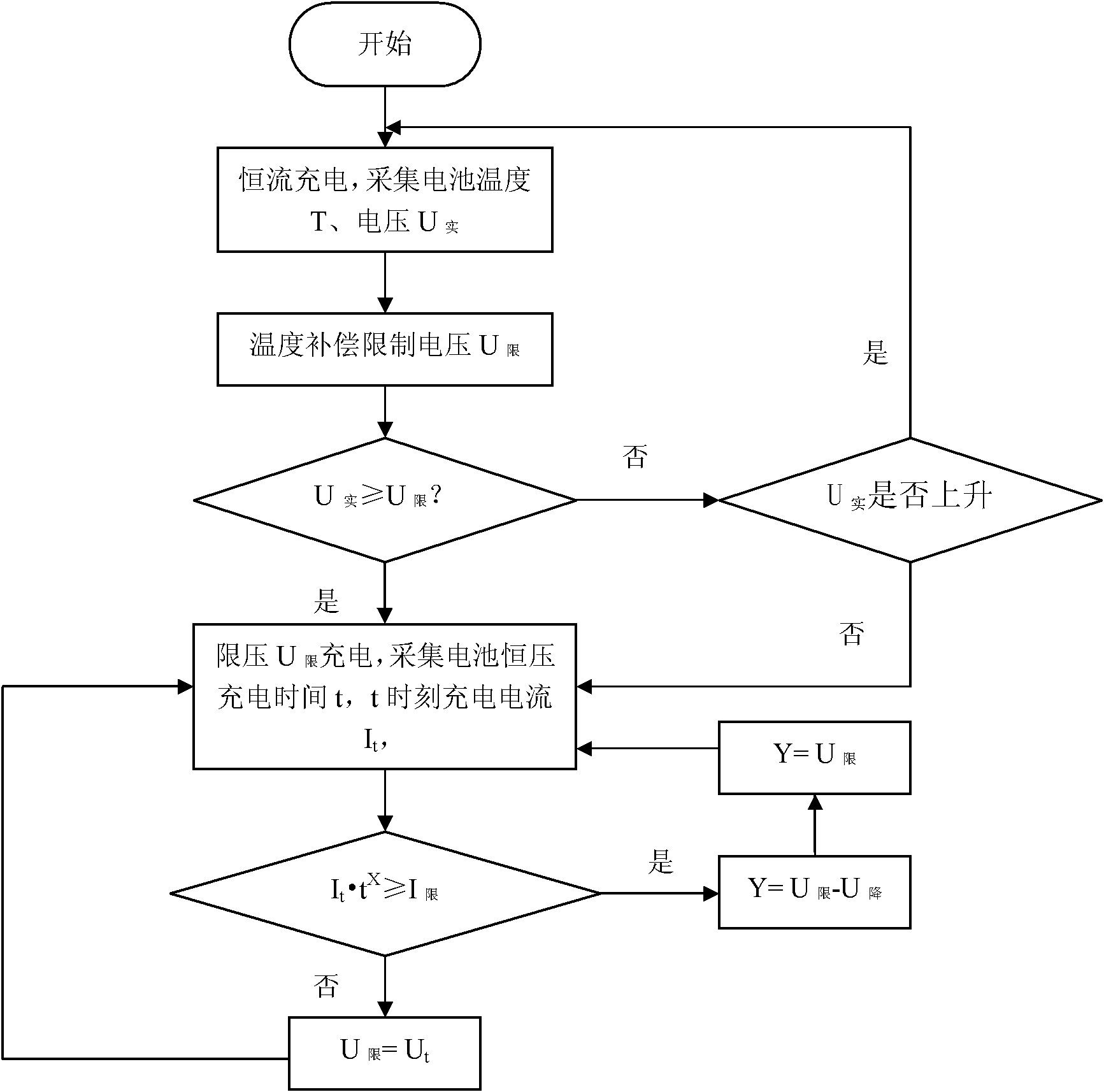

[0026] refer to figure 2 Embodiment 2 of a battery charging method of the present invention, a battery charging method, is carried out in accordance with the following steps:

[0027] A. First measure the temperature T of the battery, according to U 限 =n[U 25℃ +k(T-25)] formula to calculate battery charging limit voltage U 限 value, where U 25℃ It is the battery charging limit voltage at 25°C, the range is 2.35~2.50V / cell; k is the temperature compensation coefficient, the range is -5~-2mV / °C; n is the number of cells connected in series; the battery is charged with constant current, The constant current value is 0.05 to 0.5 times the rated capacity value of the two-hour rate of the battery;

[0028] B. Collect battery voltage U every 600 seconds 实, compare U 实 and battery charge limit voltage U 限 value, if U 实 ≥U 限 , then the battery enters the limited voltage charging stage and adopts U 限 Charging; if the battery voltage U 实 Battery charging limit voltage U not re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com