Organic el element surface sealant, method for producing display, and display

A technology for display devices and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, lighting devices, etc., and can solve problems such as terminal blockage, easy flow of sealants, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

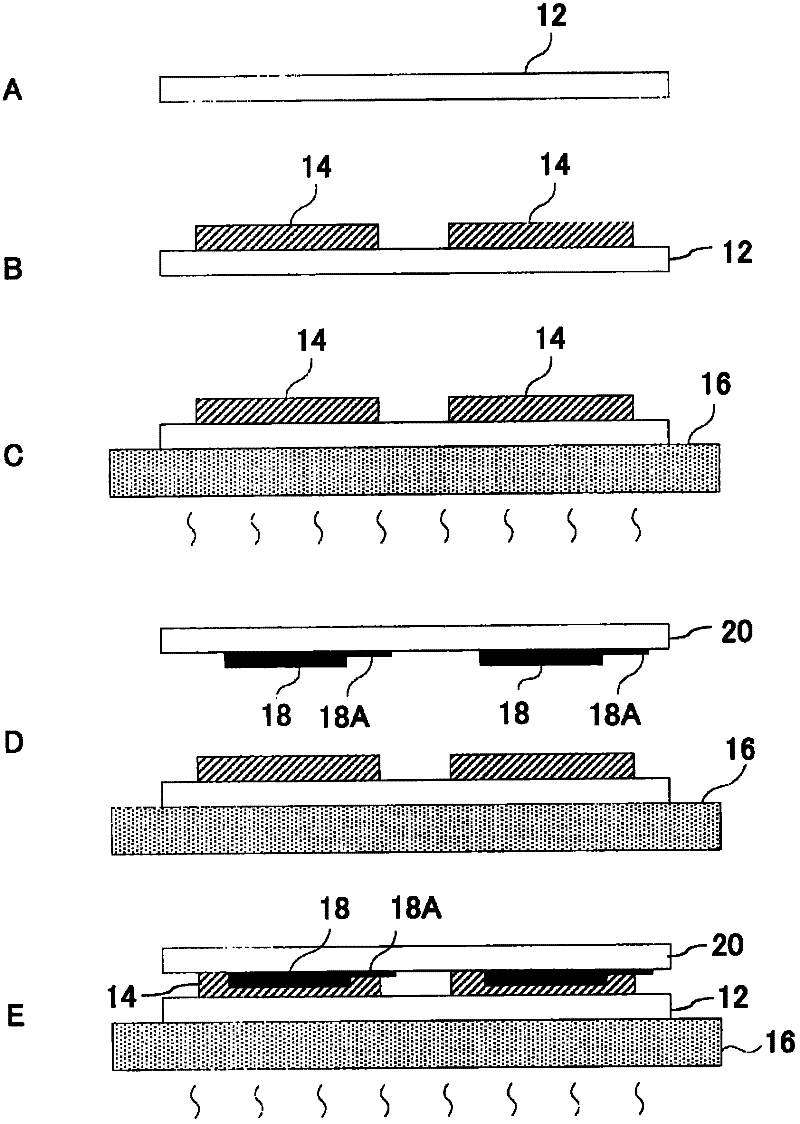

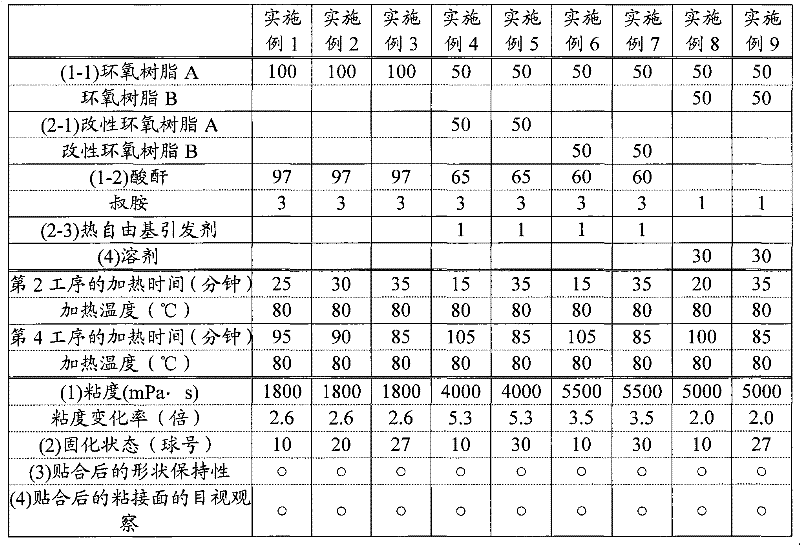

[0131] 1. Preparation of Sealants

[0132] 100 parts by weight of epoxy resin A and 97 parts by weight of tetrahydromethylphthalic anhydride (RIKASHIDDO MH700, manufactured by Nippon Rika Co., Ltd.) were added to a stirring vessel, and stirred and mixed at 25° C. for 1 hour. 2 parts by weight of γ-glycidoxypropyltrimethoxysilane (KBM-403, manufactured by Shin-Etsu Silicone Co., Ltd.) and 3 parts by weight of tris(dimethylaminomethyl)phenol were added to the mixture. (JER cure 3010, manufactured by Japan Epoxy Resin Co., Ltd.), and then stirred and mixed at 25° C. for 0.5 hour to prepare a sealant.

[0133] (1) Viscosity and storage stability

[0134] The viscosity (initial viscosity) of the prepared sealant was measured with an E-type viscometer at 25° C. and 1.0 rpm.

[0135] Further, the viscosity of the sealant after storage at 25° C. for 24 hours was measured with an E-type viscometer at 25° C. and 1.0 rpm. The ratio of the viscosity after storage to the viscosity befor...

Embodiment 2~3

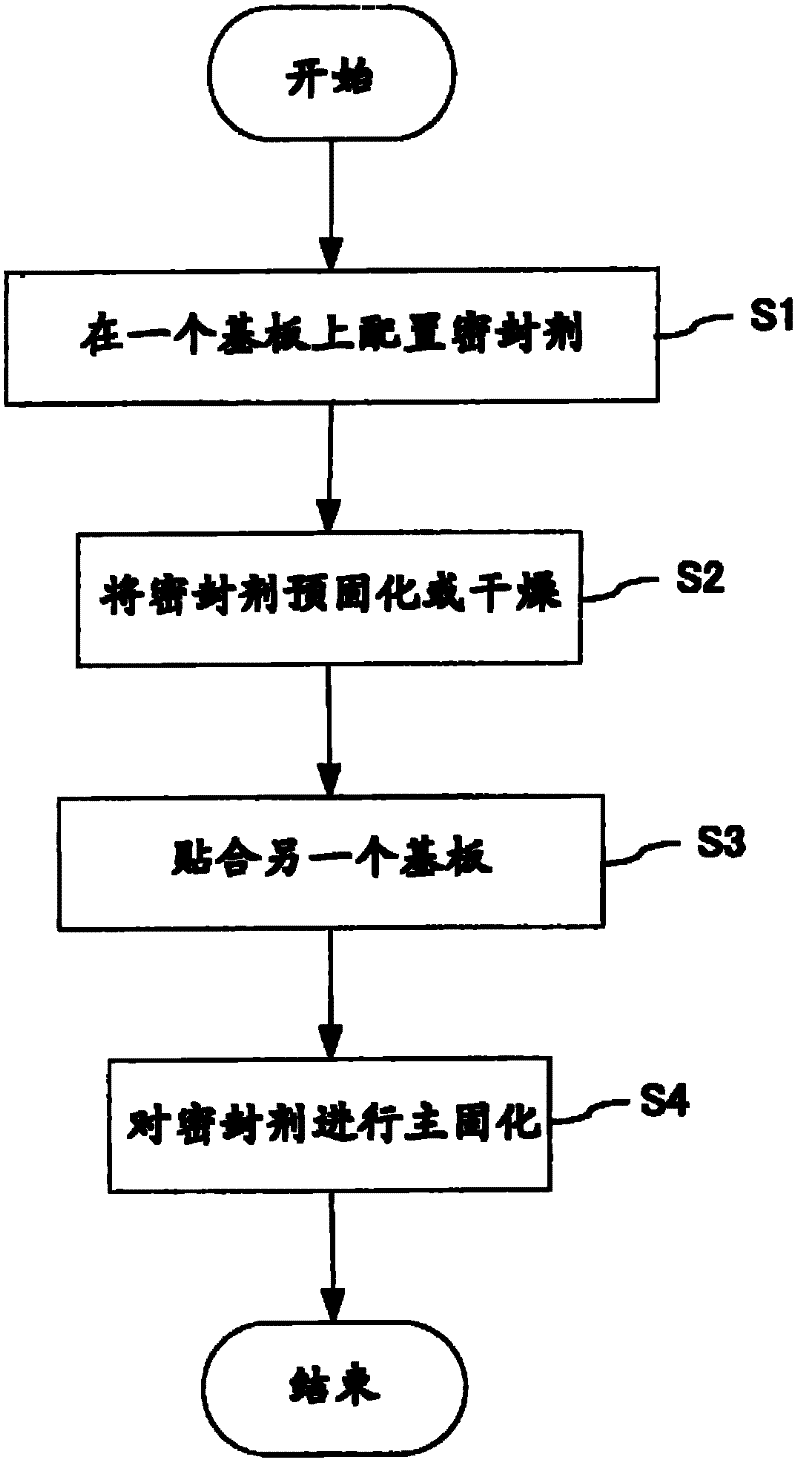

[0150] 2. Except having changed the heating time in the 2nd process of the manufacturing method of a display device, and the 4th process as shown in Table 1, it carried out similarly to Example 1, and prepared the sealing compound.

Embodiment 4~9

[0152] The sealing compound was evaluated in the same manner as in Example 1, except that the composition of the sealing compound and the heating time in the second step and the fourth step of 2. Display device manufacturing method were changed as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com