Single-particle high-speed drop generator

A generating device and high-speed droplet technology, which is applied in the field of instruments and instruments, can solve the problems that the droplets cannot be ejected in the direction of high initial velocity, and cannot accurately produce small-sized droplets, etc., and achieve electrical signal safety and power consumption. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

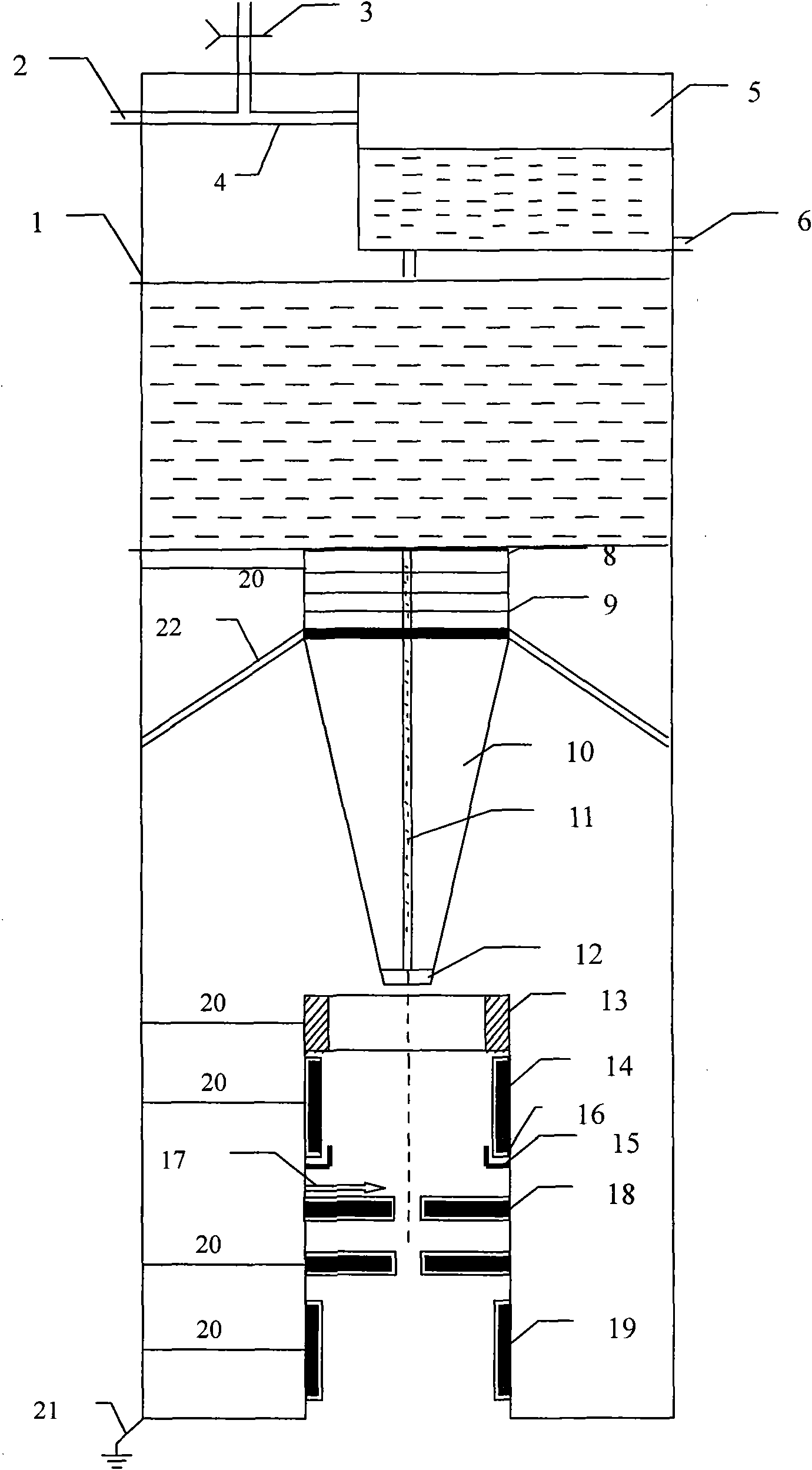

[0014] The invention comprises a housing 1, a droplet generating device, and a droplet parameter adjustment device. A buffer gas-water tank 5 is arranged above the droplet generator, and a droplet parameter adjustment device is arranged below. The buffer gas-water tank 5 communicates with the liquid through a liquid pipe. The drop generator is connected. The distance between the droplet nozzle 12 on the droplet generating device and the charging ring 13 on the droplet parameter adjustment device is 10-30 millimeters, and the droplet nozzle 12 coincides with the center line of the charging ring 13;

[0015] The droplet generating device includes: constant pressure air pump interface 2, air release valve 3, buffer gas water tank 5, the bottom of the buffer gas water tank 5 is provided with an injection / drainage port 6, the injection / drainage port 6 is connected to the device shell 1, and the buffer gas The upper part of the water tank 5 is provided with a hose 4, and the hose 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com