Tensile bending forming process of complex section bar

A forming process and profile technology, applied in the field of profile bending, can solve problems such as quality defects, achieve good forming quality, reduce springback and residual stress, and reduce cracking defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

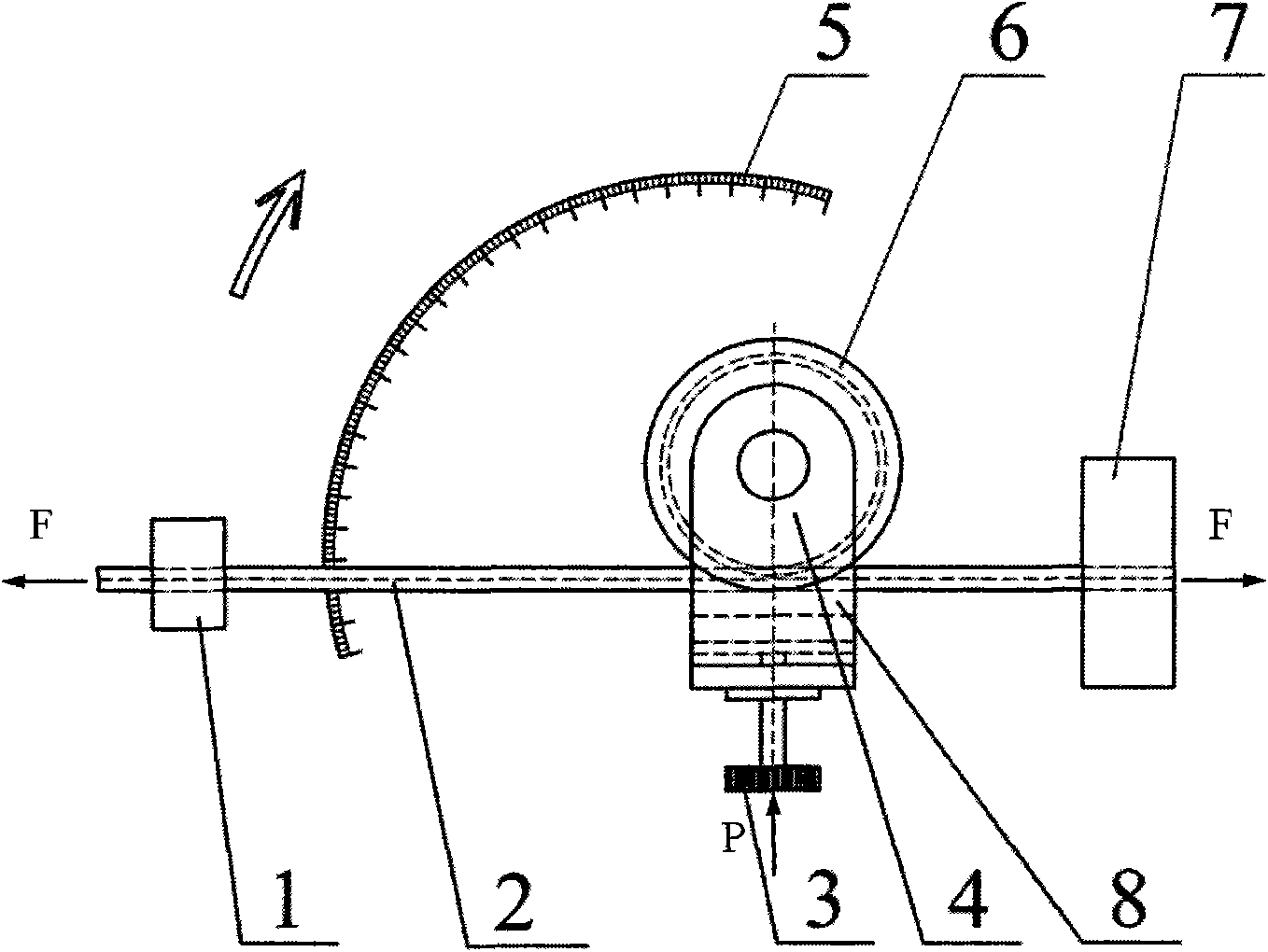

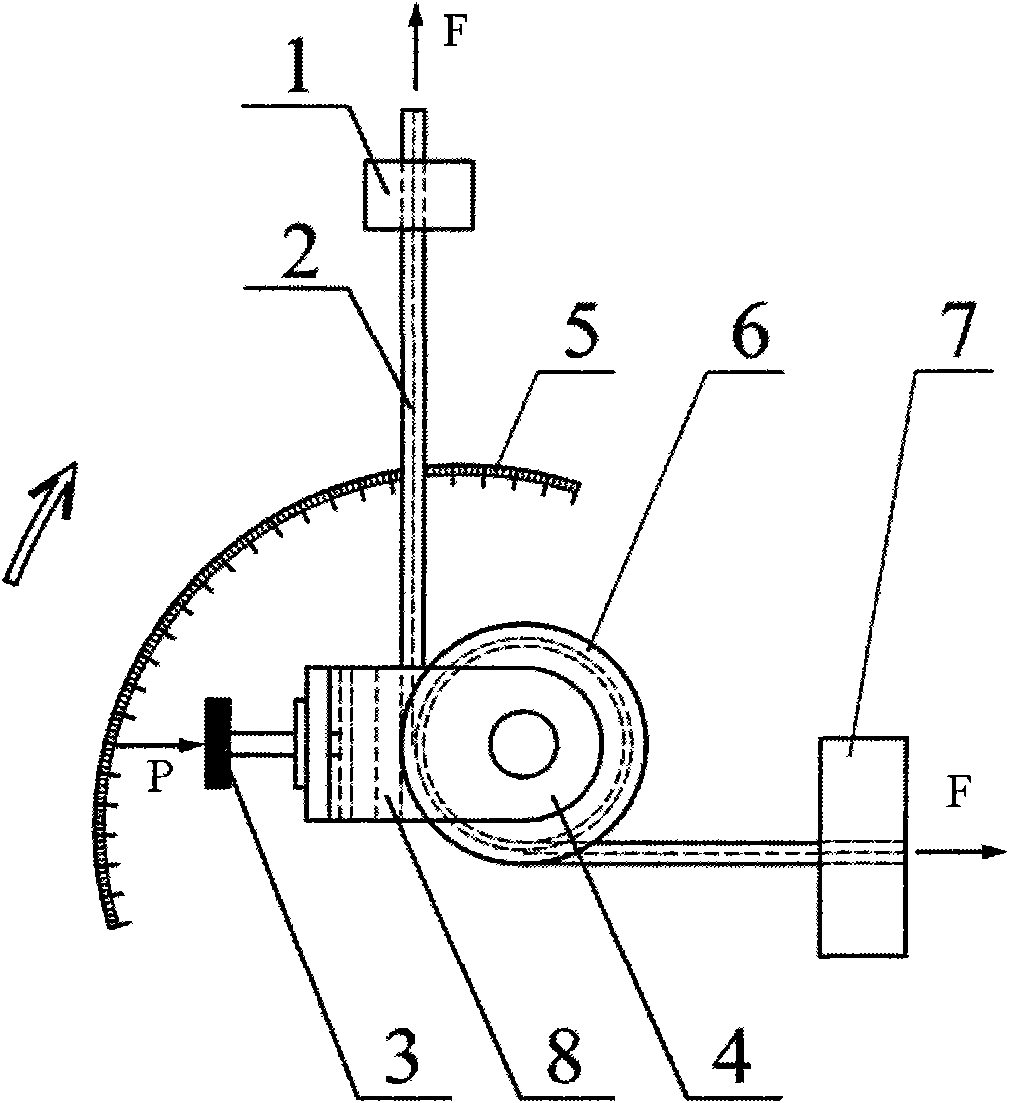

[0021] Such as Figure 1-2 As shown, the complex profile tension bending forming device of the present invention includes a stretching device 1, a profile 2, an adjustment mechanism 3, a movable mold 4, a scale 5, a concave mold cavity 6, a chuck 7, etc., and the specific structure is as follows:

[0022] The movable mold 4 is set corresponding to the concave mold cavity 6, so that the bending radius, bending angle and cross-sectional shape of the processed part are formed between the concave mold cavity 6 and the movable mold 4; one end of the movable mold 4 is provided with an adjustment mechanism 3, and the movable mold The sliding body 8 in 4 is connected with the adjustment mechanism 3, and the sliding body 8 is advanced or retreated through the adjustment mechanism 3, and the other end of the movable mold 4 is connected with the concave mold cavity 6 through a shaft; one end of the profile 2 is installed in the chuck 7, The other end of the profile 2 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com