Process for manufacturing centrifugal concrete pile

A manufacturing process and technology of concrete piles, applied in the direction of reinforcement molding, etc., can solve problems such as low production efficiency, lower vertical bearing capacity of single piles, and high brittleness of prestressed concrete piles, so as to improve horizontal bearing capacity and avoid brittle fracture problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

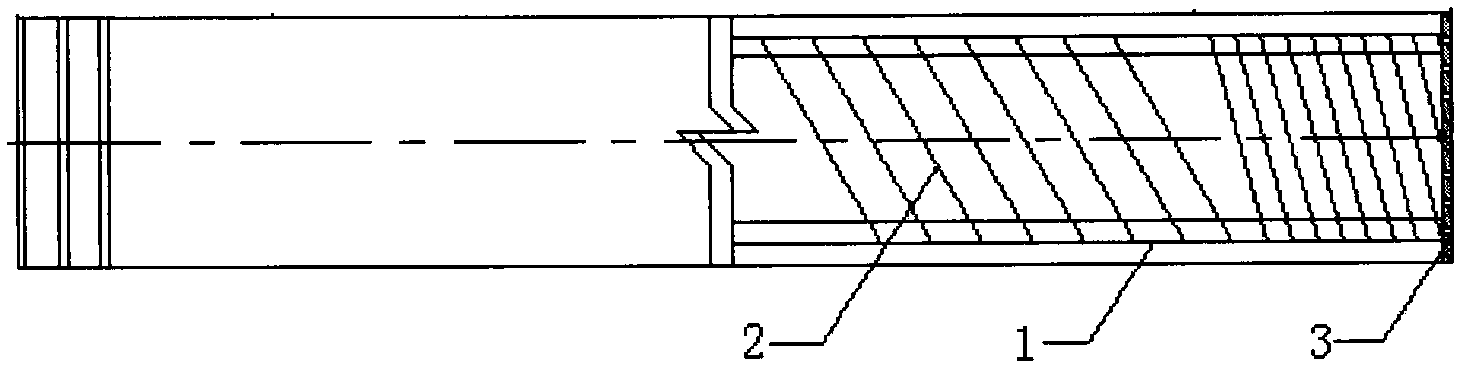

[0030] like figure 1 , figure 2 and Figure 4 As shown, the manufacturing process of the centrifugal concrete pipe pile is as follows:

[0031] (1) To make a reinforcement cage, distribute the main reinforcement 1 evenly along the cross section, the number of which shall not be less than 6; The pitch of the annular stirrups and the pitch of the spiral stirrups are not greater than 45mm, and the spacing of the rest of the annular stirrups and the pitch of the spiral stirrups are not greater than 80mm, and then the prepared reinforcement cage is placed in the lower mold;

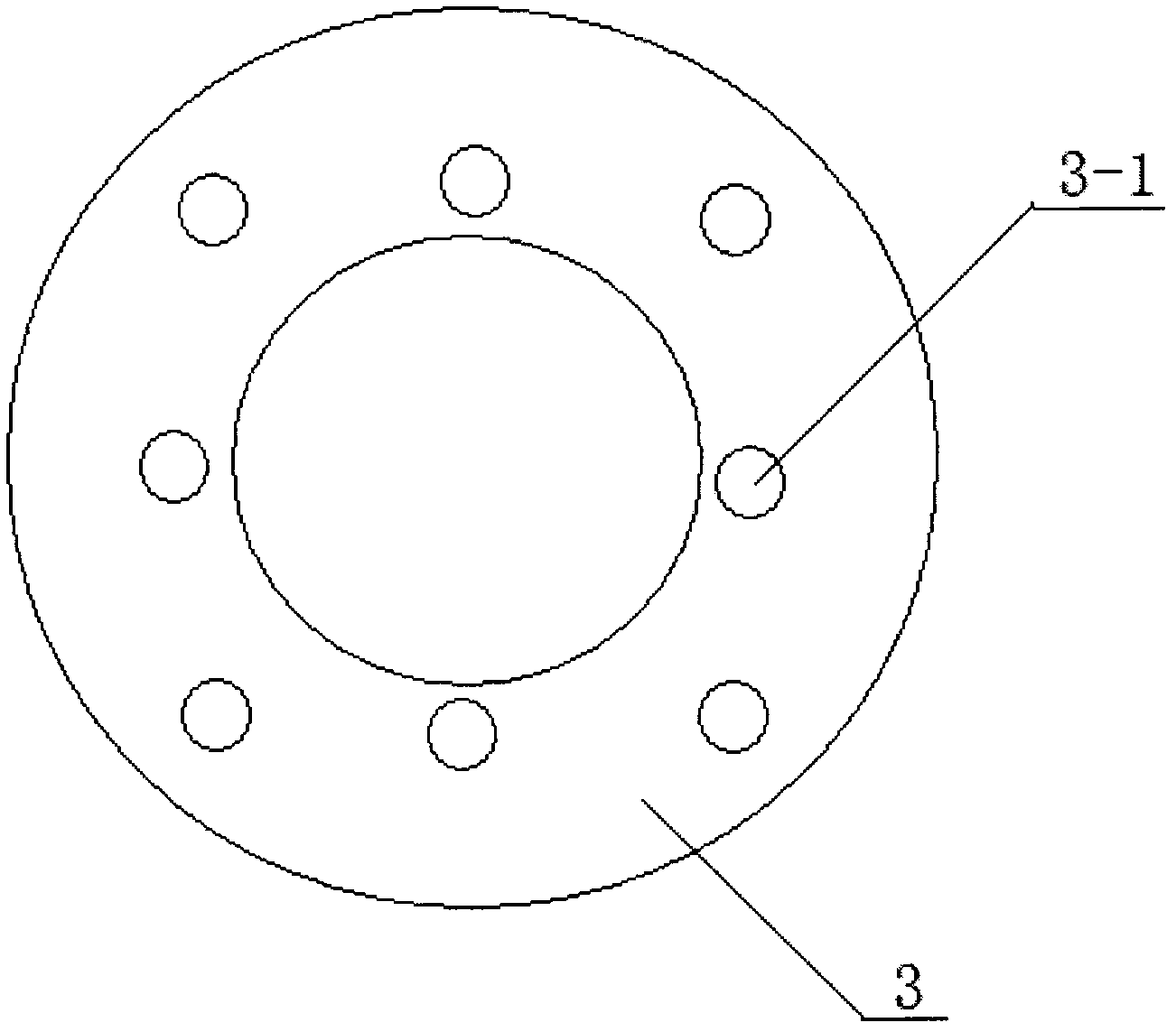

[0032] (2) According to the structure of the reinforcement cage, the annular end plate 3 is used, and the counterbore 3-1 with the same number as the main reinforcement is opened on the position corresponding to the main reinforcement on the end plate, and the bottom hole is located inside the end plate; the main reinforcement penetrates the counterbore After 3-1, weld with the end plate;

[0033] (3) Cem...

Embodiment 2

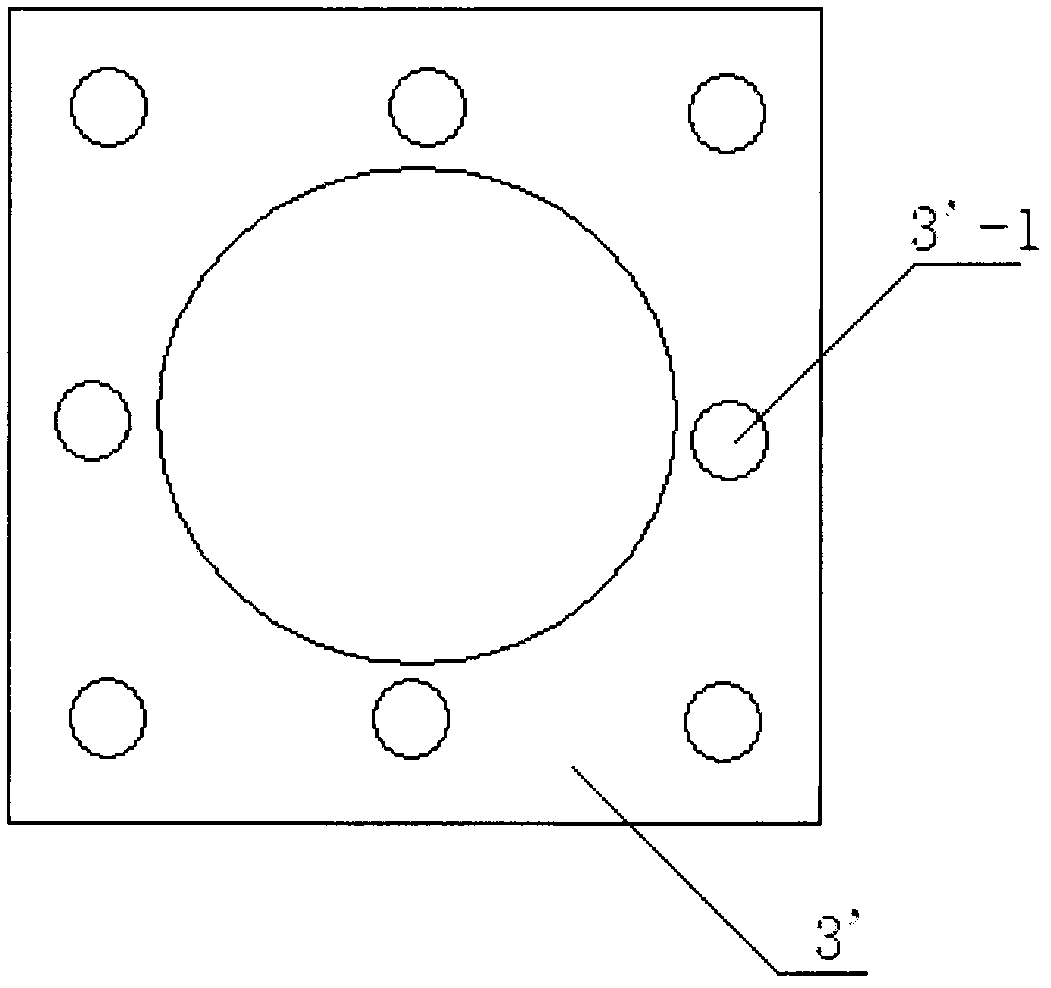

[0039] like figure 1 , image 3 and Figure 4 As shown, the difference between the manufacturing process of the centrifugal concrete square pile and the pipe pile lies in the selection of the end plate and the mold, and the other processes are the same as the pipe pile, so they will not be repeated here.

[0040] The pile produced by the process of the invention is compared with similar products, and the Φ400(95)-C80 type prestressed high-strength concrete pipe pile (PHC) is used for comparison.

[0041] PHC 400A 95-C80 prestressed high-strength concrete pipe pile, the main reinforcement adopts 7Φ9.0 prestressed steel rods, the tensile strength of the prestressed steel rods is not less than 1420MPa, and the non-proportional extension strength is not less than 1280MPa. The effective precompression stress of pipe pile concrete is 4.30MPa, and the main mechanical performance indicators are as follows:

[0042] Design value of pile body flexural bearing capacity: [M]=64KN·m

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Non-proportional tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com