Conical piece hoisting device

A hoisting device and cone-shaped technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of low efficiency, easy to bruise workpieces, etc., and achieve the effects of convenient adjustment, less bruises, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

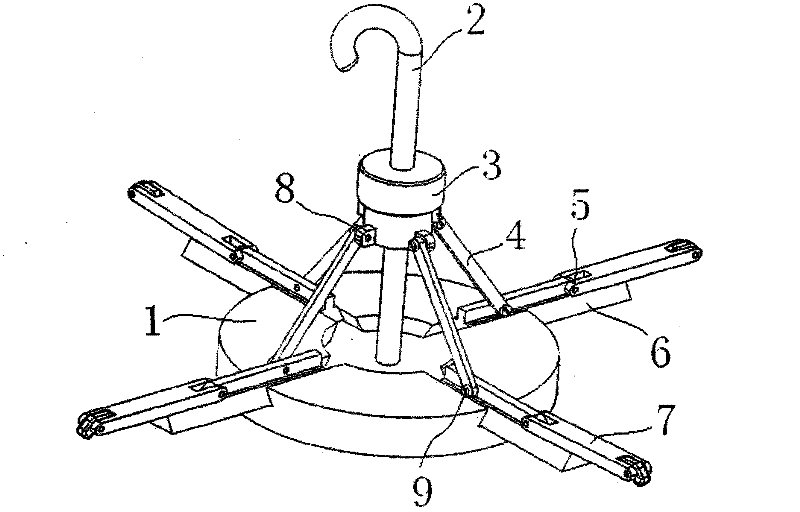

[0021] This embodiment is a hoisting device for a cone.

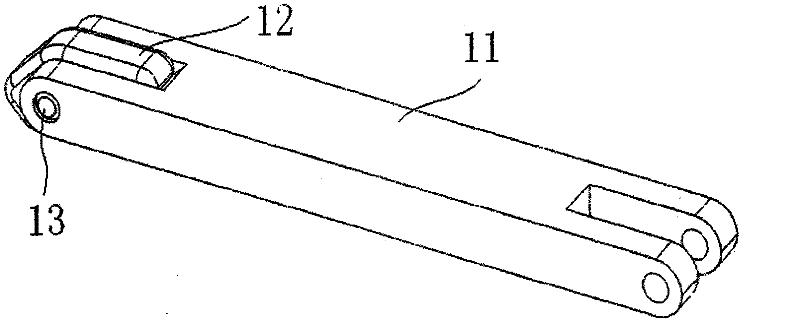

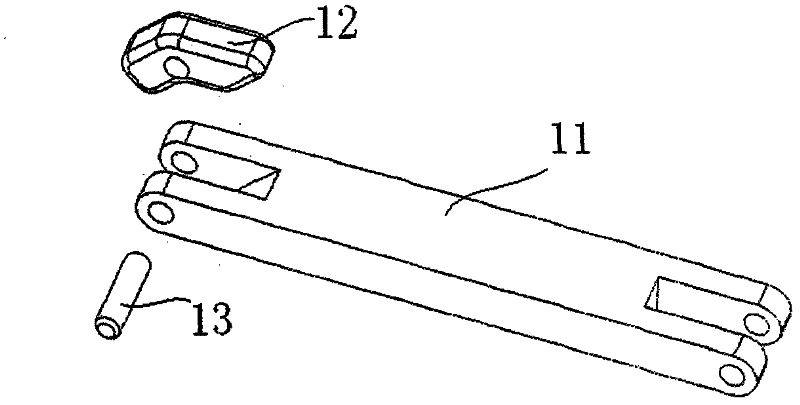

[0022] Such as figure 1 As shown, this embodiment includes a chassis 1 , a boom 2 , an adjustment mechanism 3 , a pull rod 4 , a pin shaft 5 , a slider 6 and a bar body 7 . There is a circular groove in the center of one surface of the chassis 1, and three slider grooves communicating with the groove are evenly distributed around the groove. The slider groove is a trapezoidal groove distributed radially along the chassis 1 . There is a threaded through hole for fixing the suspender 2 in the center of the groove; three sliders 6 having the same cross-section as the slider groove are respectively located in the slider groove, and the two slopes of the slider and the slider groove are clearance fits. A pressing bar body 7 is installed on the upper surface of the slider 6 . The pin hole on the slide block 6 is concentric with the pin hole on the pressure bar 11, the pin hole on the slide block 6 is in clearance fit with ...

Embodiment 2

[0034] This embodiment is a hoisting device for a cone.

[0035] Such as figure 1As shown, this embodiment includes a chassis 1 , a boom 2 , an adjustment mechanism 3 , a pull rod 4 , a pin shaft 5 , a slider 6 and a bar body 7 . There is a circular groove at the center of one surface of the chassis 1, and four slider grooves communicating with the groove are evenly distributed around the groove. The slider groove is an inverted V-shaped groove distributed radially along the chassis 1 . There is a threaded through hole for fixing the suspender 2 in the center of the groove; 4 sliders 6 having the same cross-section as the slider groove are respectively located in the slider groove, and the two slopes of the slider and the slider groove are clearance fits. A pressing bar body 7 is installed on the upper surface of the slider 6 . The pin hole on the slide block 6 is concentric with the pin hole on the pressure bar 11, the pin hole on the slide block 6 is in clearance fit with...

Embodiment 3

[0047] This embodiment is a hoisting device for a cone.

[0048] Such as figure 1 As shown, this embodiment includes a chassis 1 , a boom 2 , an adjustment mechanism 3 , a pull rod 4 , a pin shaft 5 , a slider 6 and a bar body 7 . There is a circular groove in the center of one surface of the chassis 1, and 6 slider grooves communicating with the groove are evenly distributed around the groove. The slider groove is a T-shaped groove distributed radially along the chassis 1 . There is a threaded through hole for fixing the suspension rod 2 in the center of the groove; 6 sliders 6 having the same cross-section as the slider groove are respectively located in the slider groove, and the two slopes of the slider and the slider groove are clearance fits. A pressing bar body 7 is installed on the upper surface of the slider 6 . The pin hole on the slide block 6 is concentric with the pin hole on the pressure bar 11, the pin hole on the slide block 6 is in clearance fit with the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com