Transfer protective film punching and laminating mold, punching and laminating machine and punching and laminating combination method

A technology of protective film and stamping machine, which is applied in the direction of metal processing, etc., can solve the problems affecting the subsequent composite bonding process, the troubles of composite bonding process, and low work efficiency, and achieve simple and reasonable structure, fast processing speed, and easy operation. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

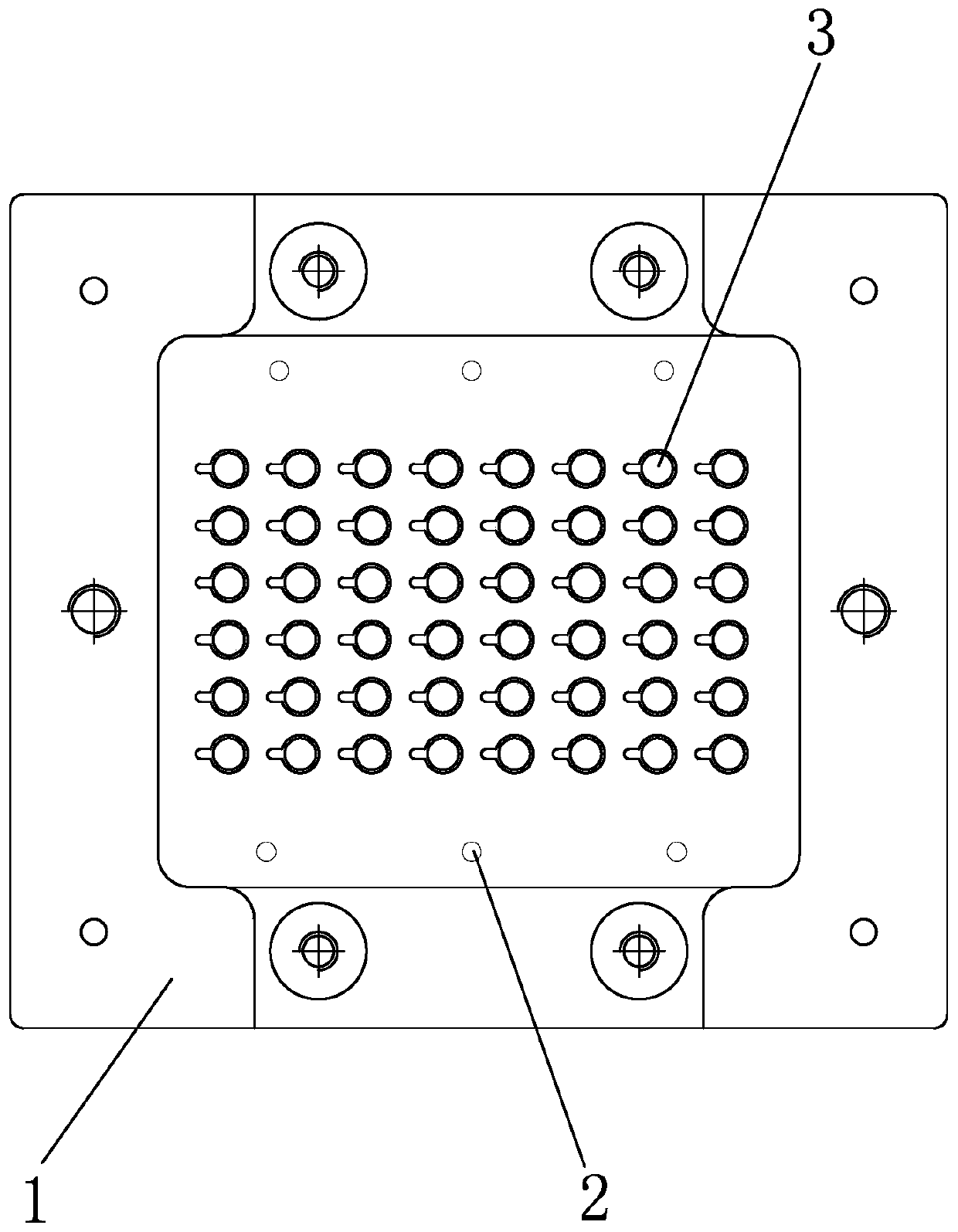

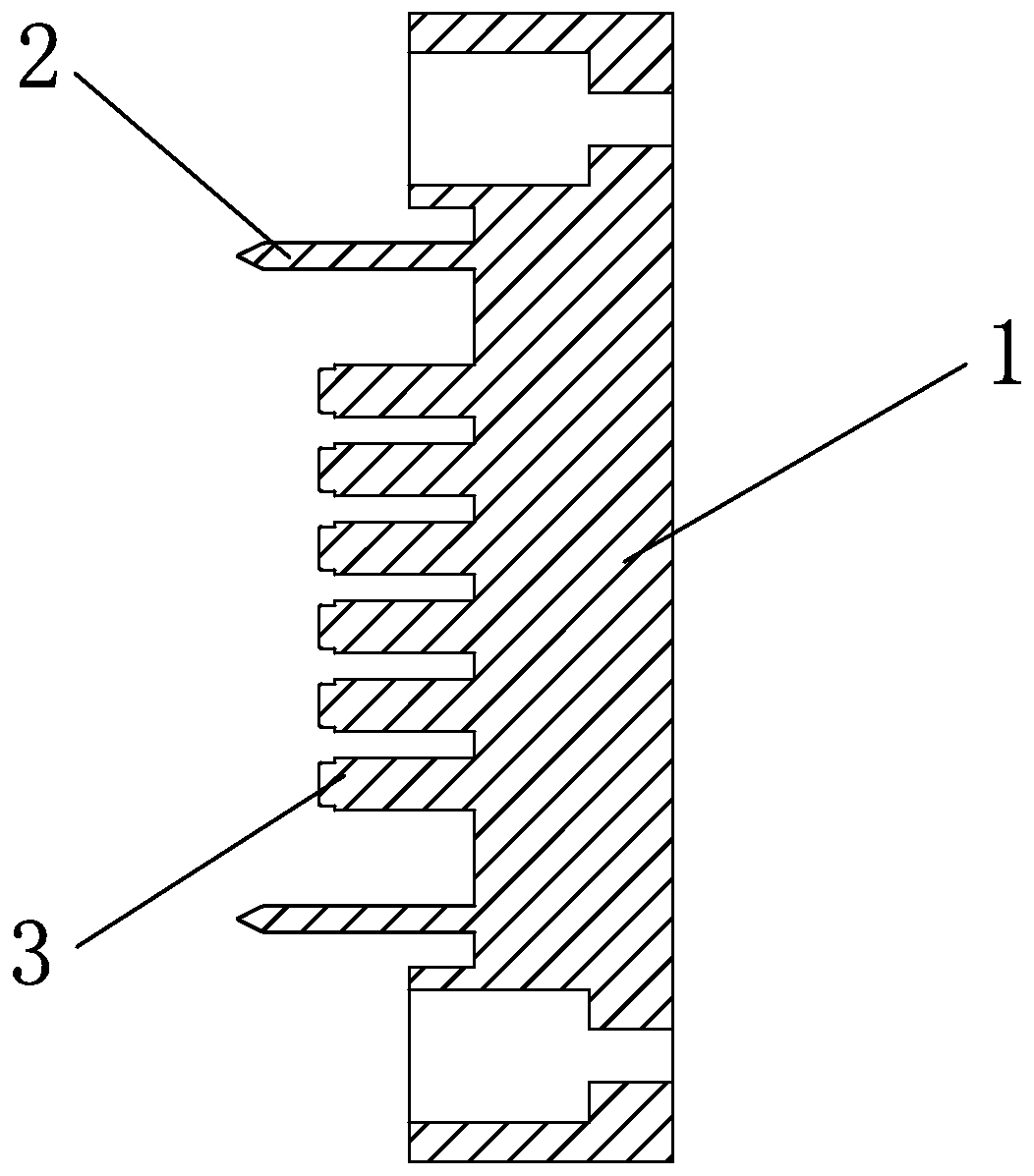

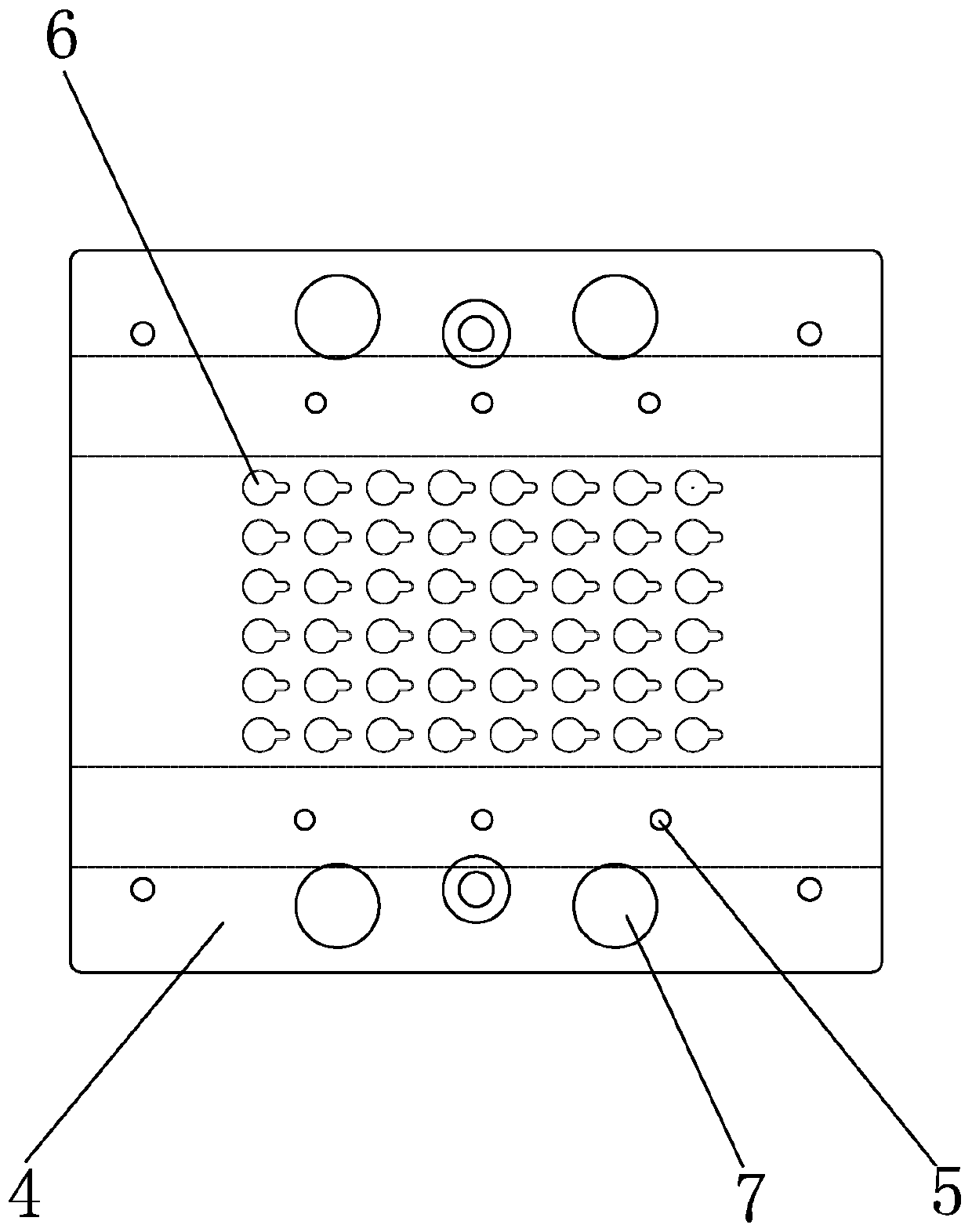

[0028] combine Figure 1 to Figure 4 , the invention discloses a stamping die for a transfer protective film, which includes an upper die and a lower die that cooperate with each other. The upper mold includes an upper mold template 1 , and positioning pins 2 and punching pins 3 arranged on the upper mold template 1 . The punching pins 3 are arranged in an array in the middle of the upper mold template 1 , and the positioning pins 2 are located outside the punching pins 3 . The punching needle 3 has a cylindrical structure, and a boss is provided on the front end of the punching needle 3 to converge inwardly. Preferably, the height of the boss at the front end of the punching pin 3 is less than 2 mm, preferably 0.8-1.3 mm. The positioning pin 2 is a needle body structure with a tapered front end and a cylindrical body; the lower mold includes a lower mold template 4 . A punching hole 6 matched with the punching pin 3 and a positioning hole 5 matched with the positioning pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com