Basic programming system (BPS) automatic deflection correction method and system for crane cart

An automatic deviation correction and crane technology, applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems of wheel and track wear, motor burnout, large wheel and track wear, etc., to eliminate the deformation of the main girder, The effect of high detection accuracy and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of BPS automatic correction method of crane cart, this method is respectively to set a bar code belt on the side of guide rail of left and right sides respectively; Simultaneously, corresponding bar code reader is installed on vehicle frame; The barcode readers on the right sides are installed on the frame near the driving wheels respectively; the control unit timely collects and compares the values of the barcodes read by the readers on both sides, and judges whether the strokes of the driving wheels on the left and right sides of the cart are synchronized; When the driving wheels on both sides are not synchronized, the control unit automatically adjusts the driving wheels on both sides by reducing the speed of the driving wheel on the leading side or increasing the speed of the driving wheel on the trailing side to keep the two driving wheels in the same bar code segment; the control unit controls the frequency converter The output frequency is u...

Embodiment 2

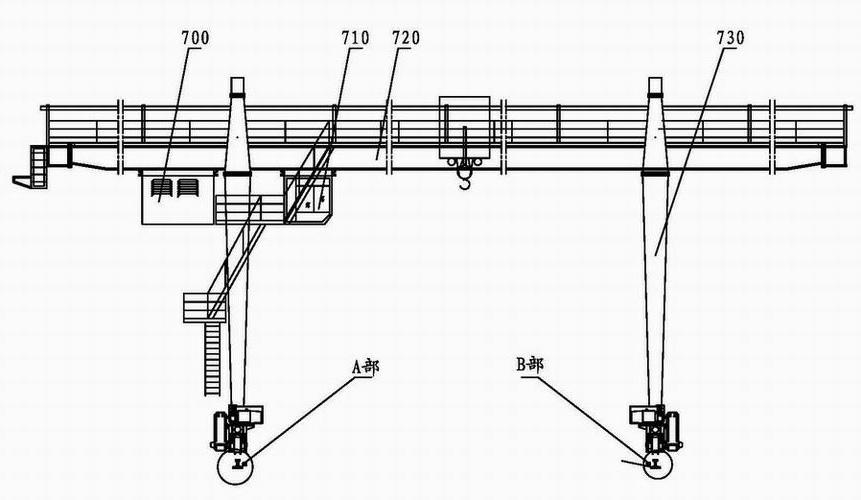

[0027] Embodiment two: if Figure 1 ~ Figure 4 As shown, a BPS automatic deviation correction system for a crane cart, including the cart, the cab and the electrical room are installed on the cart, the linkage platform +40-S40, the PLC master station and the touch screen-HMI are installed in the cab 710, and others Electrical components are housed in the electrical compartment 700 .

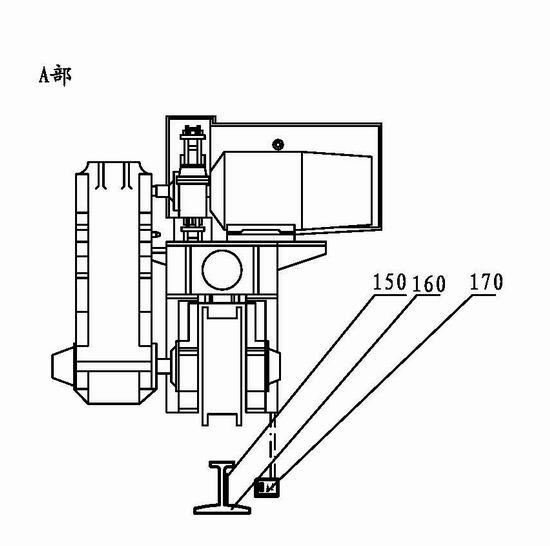

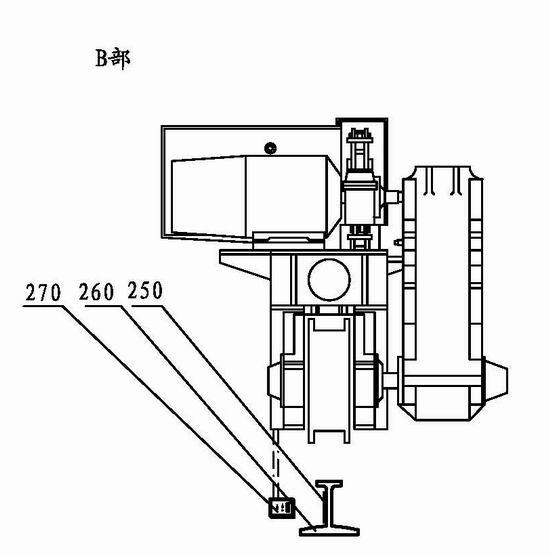

[0028] The automatic deviation correction device of the BPS cart of the crane mainly includes the left barcode tape 150 and the right barcode tape 250, which are respectively pasted on the left rail 160 and the right rail 260 of the cart (usually installed together with the drag line slot), the left barcode reader 170 and the right barcode reader 270 are respectively installed on the left and right leg frames of the cart (on the frame near the driving wheel), the left and right barcode readers are connected to the PLC slave station through the field bus profibus, and the linkage station +40-S40 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com