Method for harmlessly treating livestock and poultry breeding waste water

A technology for harmless treatment of wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as polluting the environment, reducing livestock and poultry wastewater, and achieve high efficiency , simple process, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

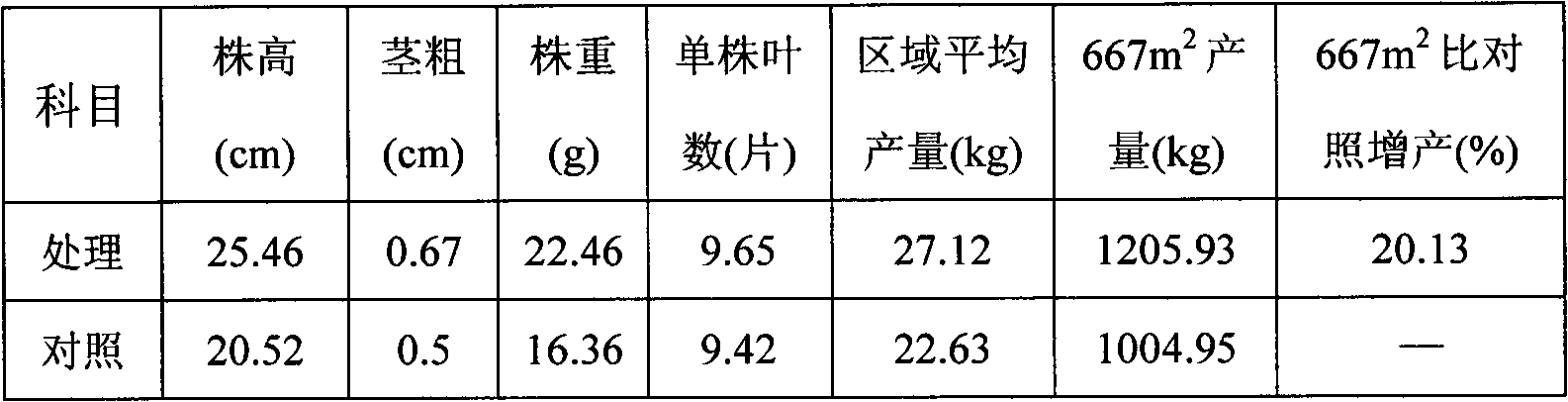

Embodiment 1

[0032] After introducing the livestock and poultry wastewater into the regulating tank, add the auxiliary agent (including 30% deodorant and 70% microbial regulator) through a liquid injector according to the amount of wastewater, and then proceed to ultrasonic reactor treatment. The ultrasonic frequency is 40kHZ and the ultrasonic intensity is 50W / cm 2 , Ultrasonic time is 20min each time, there are 5min interruptions, and a total of 48h is treated; in this step, the aeration device, such as the aeration pipe connected to the fan and the aeration pipe, can be treated for 1h each time. Aeration is performed intermittently for 20 minutes to prevent the anaerobic odor of the wastewater; the treated wastewater from the regulating tank is passed through the coarse screen to remove the larger solids to obtain the first-level separation. After the separated liquid is introduced into the separation tank, it passes through the liquid injector Add additives (including 30% deodorant, 70% ...

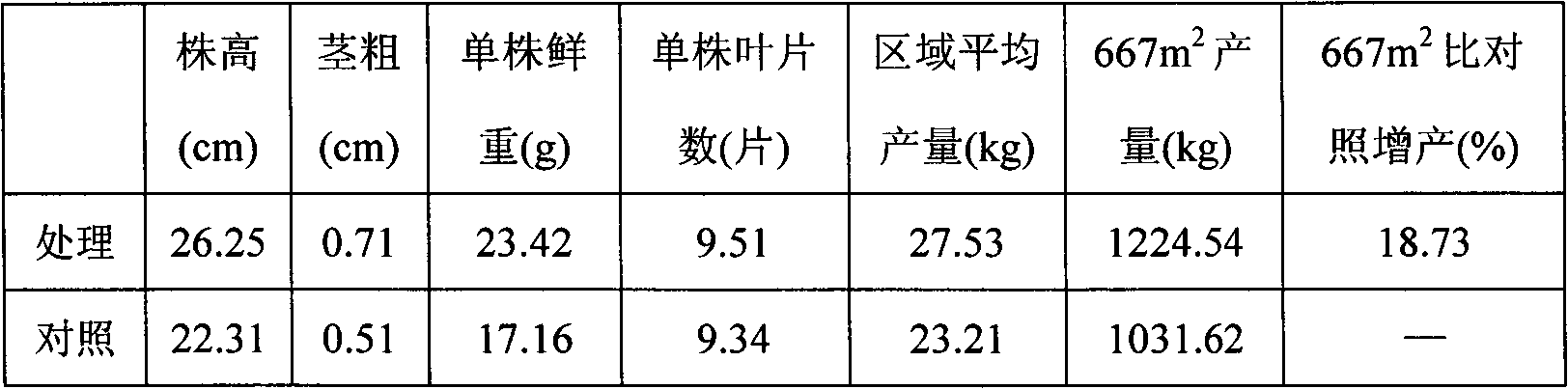

Embodiment 2

[0035] After introducing the livestock and poultry wastewater into the regulating tank, add additives (including 40% deodorant and 60% microbial regulator) through a liquid injector according to the amount of wastewater, and then proceed to ultrasonic reactor treatment. The ultrasonic frequency is 22kHZ and the ultrasonic intensity is 80W / cm 2 , Ultrasonic each time is 30min, there are 5min interruptions, and a total of 48h is treated; in this step, the aeration device, such as the fan and the aeration pipe connected to the fan, can be treated for 45min each time. Aeration is performed for 15 minutes with a frequency interval to prevent the anaerobic odor of the wastewater; the treated wastewater from the regulating tank is passed through a coarse screen to remove larger solids to obtain a first-level separation. After the separated liquid is introduced into the separation tank, it is injected Adding additives (including 40% deodorant and 60% microbial regulator) according to th...

Embodiment 3

[0038] After introducing the livestock and poultry wastewater into the regulating tank, add the auxiliary agent (including 40% deodorant and 60% microbial regulator) through a liquid injector according to the amount of waste water, and then proceed to ultrasonic reactor treatment. The ultrasonic frequency is 40kHZ and the ultrasonic intensity is 60W / cm 2 , Ultrasonic each time is 30min, there are 5min interruptions, and a total of 48h is treated; in this step, the aeration device, such as the fan and the aeration pipe connected to the fan, can be treated for 45min each time. Aeration is performed for 15 minutes with a frequency interval to prevent the anaerobic odor of the wastewater; the treated wastewater from the regulating tank is passed through a coarse screen to remove larger solids to obtain a first-level separation. After the separated liquid is introduced into the separation tank, it is injected Adding additives (including 40% deodorant and 60% microbial regulator) acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com