Inner slope type forged hubbed flange

A forging method and flange technology, which is applied in the field of new node connection forms, can solve the problems of large deformation and low stiffness of non-stiffened flange connections, and achieve the effects of reasonable structure, improved production efficiency and mechanization efficiency, and force coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

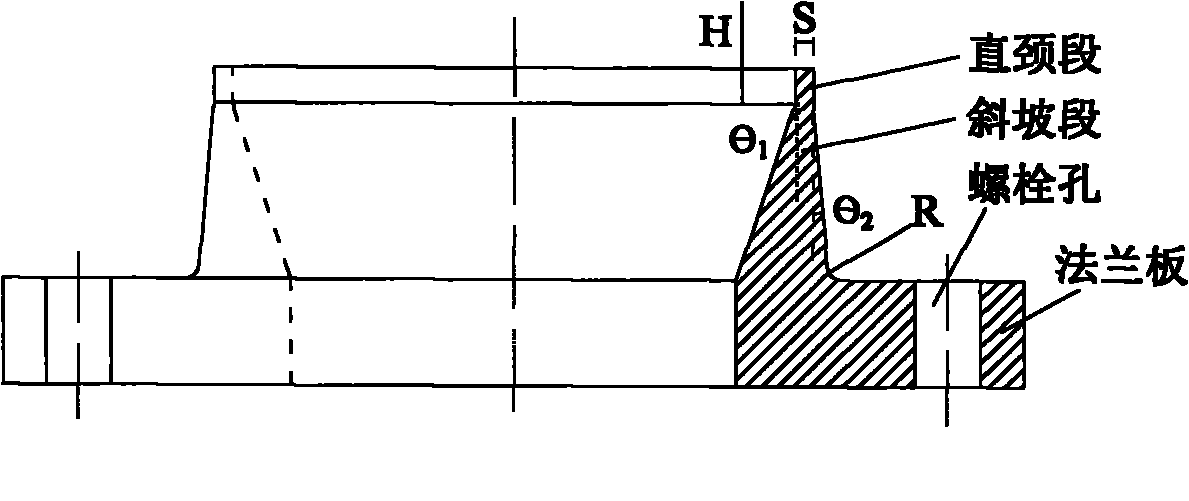

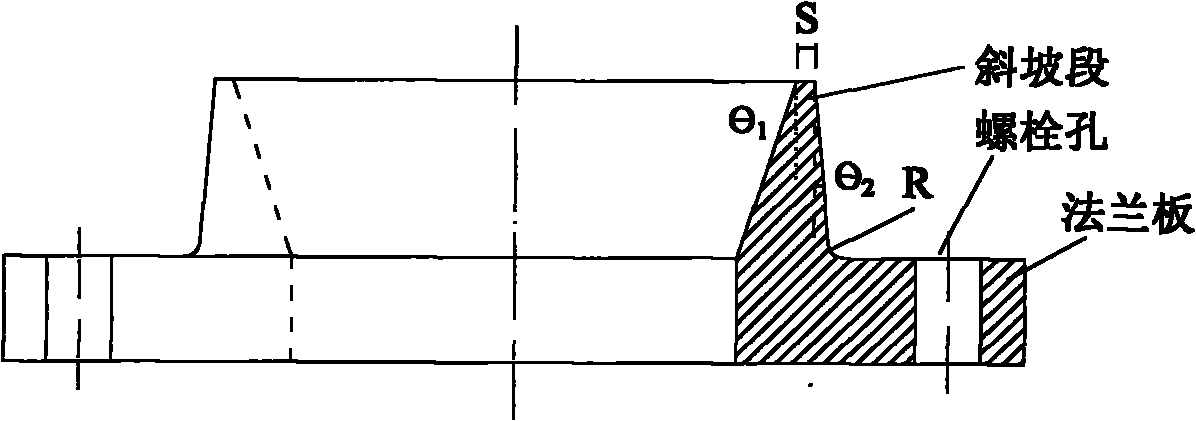

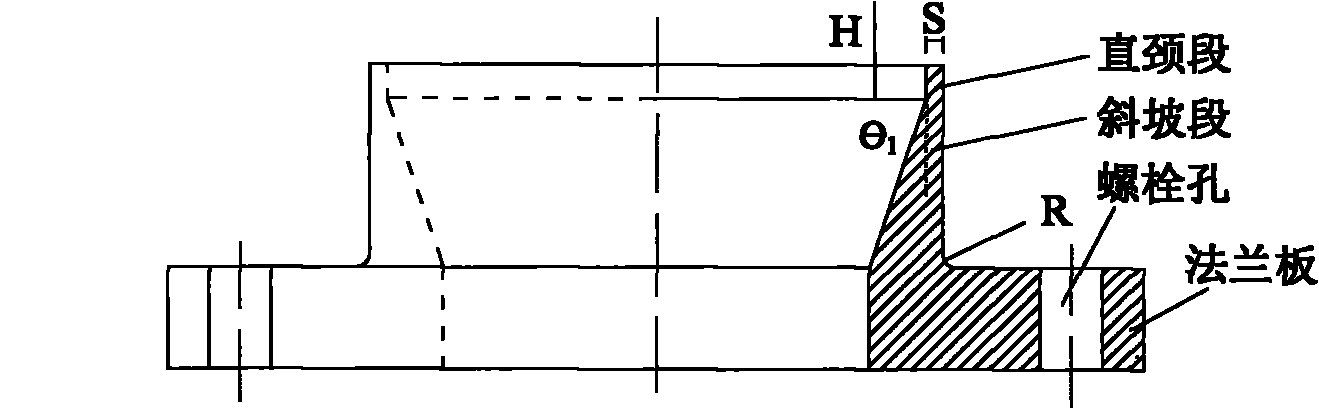

[0016] The forged neck flange is directly forged from a steel billet into a rough sample of the flange, then machined, and heat-treated to eliminate residual stress. The steel can be Q235, Q345, Q390, Q420, Q460 and other existing steel types at home and abroad. ; It is connected with the steel pipe of equal diameter by butt weld. When the wall thickness of the steel pipe and the wall thickness of the flange welding part are relatively large, the bevel should be opened according to the requirements of the welding process; the flange of the steel pipe is connected by bolts, and the bolts can be 6.8, For grades 8.8 and 10.9, the high-strength bolts are tightened according to a certain pre-tightening force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com