A structure and construction method of a perforated steel plate shear key

A technology of perforated steel plate and shear key, which is applied in the direction of building structure and construction, can solve the problems that the longitudinal shear force resistance of concrete tenons cannot be repeated, the construction difficulty of penetrating steel bars, and the integrity of damage are achieved, so as to achieve pull-out resistance The effect is good, the effect of increasing the longitudinal shear resistance and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

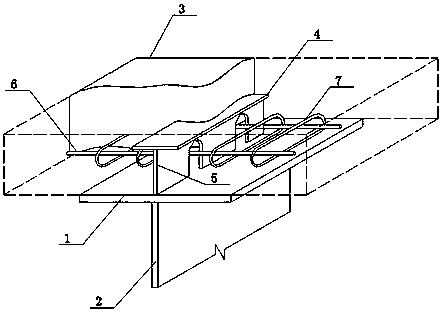

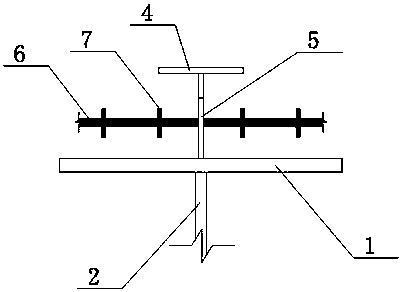

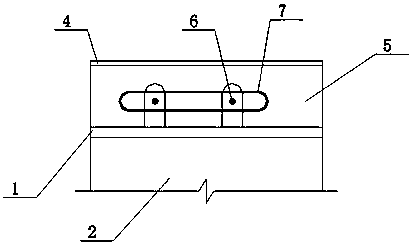

[0017] see Figure 1~3 , the structure of a kind of perforated steel plate shear key of the present invention, comprises the steel beam that is made up of steel beam flange plate 1 and steel beam web 2, is welded with T-shaped shear force key on steel beam flange plate 1, described T Shaped shear key comprises shear key flange plate 4 and has the shear key web 5 of U-shaped groove, and the thickness of described shear key web 5 is 10mm, and height is 100mm, and the opening width of U-shaped groove is 20mm, and the spacing between U-shaped grooves is 200mm. The U-shaped groove on the shear key web 5 and the steel beam flange plate 1 form a closed "door opening", and a main reinforcement 6 is arranged in the "door opening", and a closed stirrup 7 is arranged on the main reinforcement 6 .

[0018] During construction, first lay the steel beam according to the design requirements, and then weld the T-shaped shear key on the flange plate 1 of the steel beam, such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com