Semiconductor device and method for manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large forward voltage drop and component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

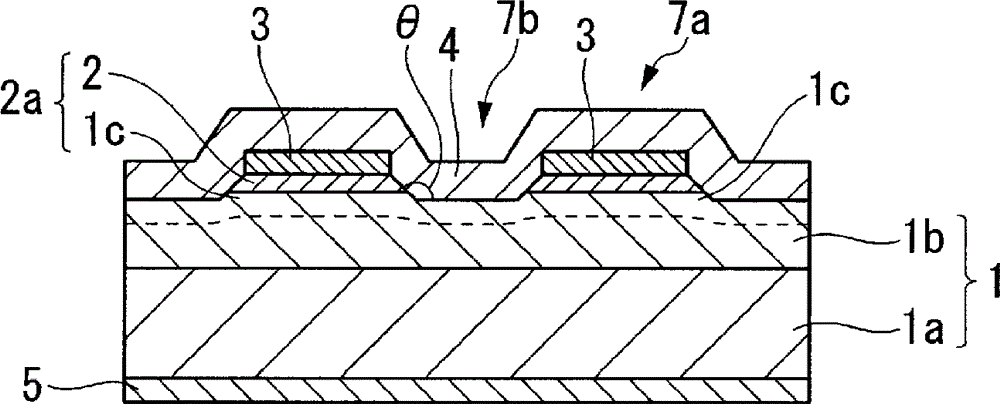

[0114] Manufactured as follows Figure 1A The Schottky barrier diode of Example 1 is shown. First, when the impurity concentration is 2E18cm -3 N + SiC layer 1a is formed on semiconductor substrate 1 with N - Type epitaxial layer growth, forming an impurity concentration of 1E16cm -3 N - SiC layer 1b, obtained with N + SiC layer 1a and N - N-type semiconductor substrate 1 of SiC layer 1b. Next, on the N of the semiconductor substrate 1 - On the SiC layer 1b, a PN junction layer (not shown) is formed by ion implantation. Specifically, using an oxide film formed by CVD (Chemical Vapor Deposition) as a mask, the N - On the SiC layer 1b, a P-type impurity made of aluminum is ion-implanted at a temperature of 600°C so that the impurity concentration is 2E19cm -3 . Thereafter, the mask made of the oxide film is removed.

[0115] Next, heat treatment is performed to diffuse and activate the P-type impurities ion-implanted into the semiconductor substrate 1 . The heat tre...

Embodiment 2

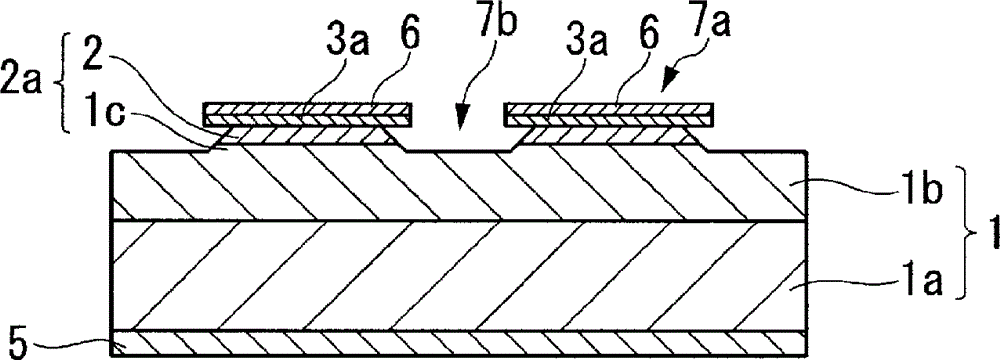

[0139] Manufactured as follows figure 2 The Schottky barrier diode of Example 2 is shown.

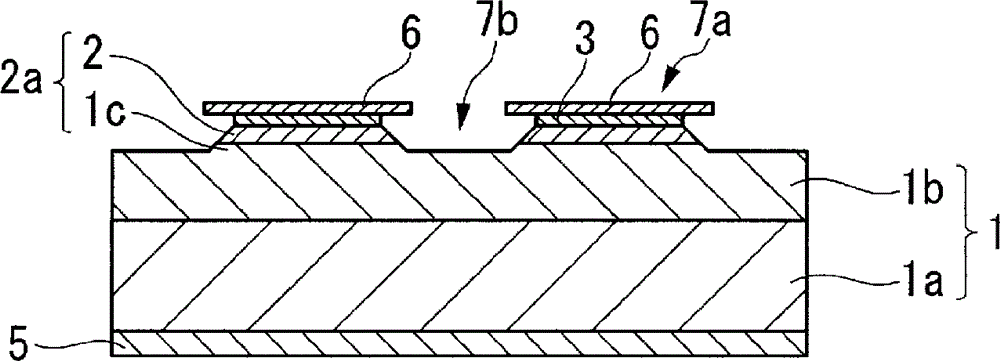

[0140] That is, in the etching process, the method of adjusting the etching conditions such as the etching rate is adopted, and the region 1d where the semiconductor substrate 1 of the Schottky junction region 7b is connected to the side surface of the convex portion 2a is made into a curved surface. In the same manner as in Example 1, the semiconductor device of Example 2 was obtained.

[0141] The relationship between the reverse current and the reverse voltage of the semiconductor devices of Example 2, Example 1, and Comparative Example thus obtained was investigated. show the result in Figure 3B . Figure 3B It is a graph showing the relationship between the reverse current and the reverse voltage of the semiconductor devices of Example 2, Example 1, and Comparative Example.

[0142] Such as Figure 3B As shown, in Example 2 and Example 1, compared with the comparative exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com